Reinforcing Fiberglass Mesh for Architectural Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Wall Mesh for Construstion Material

Product Description

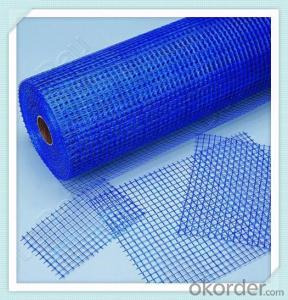

Fiberglass wall mesh Made of C or E glass fiber yarn through special weaving technique,

then coated by the anti-alkali and reinforcing agent and treated by high temperature heat finishing.

It is ideal engineering material in construction and decoration industry!

fiberglass wall mesh High Quality

1. Coating glue: our coating glue is produced by Germany BASF which can keep more than 70% after 28 days NaoH test.

2. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it is more 20% strong strength and beauty surface than normal fiberglass yarn.

fiberglass wall mesh Application

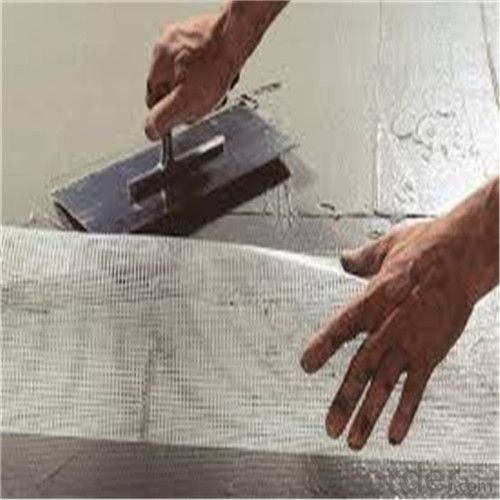

1.Fiberglass wall mesh is Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board, gypsum board, bitumen)

2. Reinforced cement products.

3. Used for Granite, mosaic, marble back mesh etc.

4.Waterproof membrane fabric, asphalt roofing.

Certificates to guarantee quality.

Passed in ISO9001:2000 certificate , IQ net, China National test, ROSH,Europe ETAG certificate

Company information :

Advantage:

1.CNBM International is a subsidiary of the CNBM Group

2.The largest building materials and equipment group in China

3.Government owned compny

4.Owned our logistics parkand in Dubai

Our service :

1.Any time you can contact with us

2.Free sample

3.If you place order ,we will update the new production process to you

4.Every order,we will make professtional inspecting

5.If you have any feedback , we will first time to make it for you

6.We will all stand your side to consider everything

Fiberglass wall mesh Payment:

T/T 30% in advance, T/T 70% against B/L copy.

FAQ:

Q: What are we doing?

A: we offer the best fiberglass mesh with the right price, we make the best ones , and also offer sourcing service for many products

Q: What are we making in our own factory?

A: we are one of the best fiberglass mesh supplier in China. We own and co-own the best fiberglass mesh factory, and we also make many accessories in our own factory, So we have many exclusive products that is only available from us.

Q: How is our customer service?

A: All our sales representatives can speak fluent English. They will answer all of your questions within 24 hours.

Q: What others can we offer?

A: Based on the wide products range, we offer the best one-step sourcing services. We will definitely save you a lot of time and money, and based on our quantity of shipment, we can get the best shipping service from the best forwarders. This will help you to save a lot on shipment.

- Q: The household is screened glass fiber gauze or stainless steel gauze.

- Of course, the glass fiber network is good, the warp and weft bonding. Yarn mesh size is constant, suitable for cleaning,

- Q: What are the requirements for wall insulation fiberglass mesh?

- Article 4.0.6 A test for alkali resistant tensile breaking strength shall be in accordance with provisions A12.2 of this Regulation appendix, fiberglass mesh alkali-resistant tensile breaking strength and alkali-resistant tensile breaking strength retention rate should be in accordance with regulations in table 4.0 .6. Table 4.0.6 Glass fiber mesh performance requirements: test items: alkali tensile breaking strength N / 50mm; alkali tensile breaking strength retention % . warp-wise, weft, warp-wise,weft. performance requirements: fiberglass mesh ≥750≥50; alkali-resistant fiberglass mesh ≥1000≥75.

- Q: Specifications of alkali resistant glass fiber gridding cloth

- Refer to the requirements of JG149JG158

- Q: What's the harm of glass fiber gridding cloth?

- Too itching. Some may cause skin allergy.

- Q: How long is a roll of mesh specially for external wall thermal insulation?

- It boasts with many advantages, such as fireproofing, insect?prevention, flexibility, high tensile resistance in the direction of warp and weft, good chemical stability, high strength and shock resistance.

- Q: What are the bonding requirements of alkali resistant fiberglass mesh? Anti cracking protection layer construction, alkali resistant fiberglass mesh cloth why not dry lap?

- The bonding width of alkali resistant fiberglass mesh shall not be less than 50mm, and the edge of alkali resistant fiberglass mesh cloth shall not be dry lapped, and must be embedded in anti cracking mortar.

- Q: Is the plastering of the window opening necessary to hanging the mesh.

- Newly renovated house, usually newly built, will produce a slight crack, but it is not serious. as for the lightweight walls, it can also use kraft paper to repair, not necessarily to use mesh.

- Q: What purposes do dry-type transformers epoxy resin mesh have ?

- 1, the product adopts high quality, wax-free, E-glass and electric fiber yarn as the substrate, knitted into a variety of mesh cloth, and is made through heat drying dehydration, and then impregnated with epoxy resin mixture unique formula, dispensing glue under moderate temperature, and heat drying curing. 2, according to the property of the impregnated resin, the products can be divided into solvent and solvent-free mesh mesh. The main differences between the two mesh are as follows: 2.1, impregnated resin is different: Solvent Mesh contains acetone, solvent-free mesh is pure resin. 2.2, different procedures of impregnation: Solvent mesh is impregnated at normal temperature air, and it is opaque; while solvent-free mesh is impregnated under the medium-temperature vacuum pressure, and the mesh is transparent. 2.3, containing different amounts of plastic: The proportion of resin contained in solvent-free mesh is much larger than a solvent mesh, about twice of the solvent mesh. 2.4 application is different: Solvent-free mesh is suitable as an insulating layer between the coils with no partial discharge at very high field intensity the use of solvent-free mesh can reduce the thickness of the interlayer insulation.

- Q: Can glass fiber gridding cloth waste be recycled? If can, then what is is?

- The acrylic in grid cloth can produce pungent smell and cause serious soil pollution after high temperature, which proves the environmental protection of glass fiber. It may cause serious air and soil pollution and contain harmful substance to respiratory system. And the core material of grid ding cloth is flame retardant and cannot be burnt.

- Q: Rock wool board insulation, why add two layers of glass fiber network, and XPS is a layer?

- Rock wool with two layers of mesh cloth and not improve crack resistance, but because wool soft texture, installing the anchor bolt after the surface is uneven, with two layers of mesh is to increase the thickness of the mortar, to find the plane. There is no such phenomenon in the extrusion board.

Send your message to us

Reinforcing Fiberglass Mesh for Architectural Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords