Fiberglass Tape FGT-180 - Packaging Tape Melbourne

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1x20' FCL roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

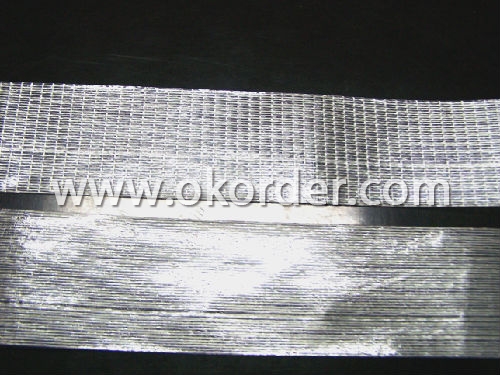

General Information of Fiberglass Tape FGT-180

Filament / fiberglass tape is with PET film and one-directional fiberglass.

2. The tape is with high tensile strength, used for palletizing, holding, bundling, reinforcing, heavy duty packing, carton packing & sealing.

3. Standard cut roll packing: one roll per plastic bag, then into cartons. We can also offer special packing as per customer's requirements, such as label, core printing and sticker.

CONSTRUCTION of Fiberglass Tape FGT-180

Backing: One directional Fiberglass + PET film

Adhesive: Hot melt rubber based adhesive

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + backing): 130micron

Initial Tack: more than 18# steel ball

Tensile Strength: more than 180N/25mm

Peel Adhesion: 13 N/25mm

Holding power: not less than 30h (1kg/25mm)

Temperature resistance: 60C

Elongation: 0.3%

Sizes of Fiberglass Tape FGT-180

Jumbo Roll: 1.02 x 1000m

Cut Roll: As per customer's requirements

Remarks of Fiberglass Tape FGT-180

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: Can packaging tape be used for sealing recreational or outdoor gear?

- Yes, packaging tape can be used for sealing recreational or outdoor gear. Packaging tape is designed to securely seal boxes and packages, providing a strong and durable seal. It can be used to repair tears or holes in gear such as tents, sleeping bags, backpacks, or tarps. Additionally, packaging tape can be used to reinforce weak points or seams in gear, adding extra strength and protection. However, it is important to note that while packaging tape can provide a temporary fix, it may not be as long-lasting or weather-resistant as specialized outdoor repair tapes. It is always recommended to use the appropriate gear repair products for a more reliable and durable solution.

- Q: Can packaging tape be used for sealing arts and crafts materials?

- Packaging tape is indeed suitable for sealing arts and crafts materials. Its versatility as an adhesive enables it to effortlessly attach and secure a wide range of materials such as paper, cardboard, fabric, and more. Whether you need to seal envelopes, wrap gifts, or engage in art projects, packaging tape guarantees a sturdy and durable bond, ensuring the secure sealing of your arts and crafts materials. Moreover, its transparent nature allows it to seamlessly blend with your project, making it an exceptional option for sealing arts and crafts materials.

- Q: Can packaging tape be used for sealing glass containers?

- Yes, packaging tape can be used for sealing glass containers. Packaging tapes are designed to provide a strong and secure seal on a variety of surfaces, including glass. When properly applied, the tape adheres firmly to the glass surface, creating a tight seal that helps to keep the contents of the container protected. However, it's important to note that not all packaging tapes are suitable for use with glass containers. It is recommended to use a tape specifically designed for glass or a heavy-duty packaging tape that has strong adhesive properties to ensure proper sealing.

- Q: Can packaging tape be used for sealing wooden crates?

- Sealing wooden crates can indeed be accomplished with packaging tape, which creates a sturdy and reliable bond. This ensures that the crate remains tightly sealed throughout transportation or storage. Packaging tape is specifically designed to adhere well to different surfaces, including wood, making it an excellent option for sealing wooden crates. Nevertheless, it's crucial to take into account the weight and dimensions of the crate before solely depending on packaging tape. In the case of heavier or larger crates, reinforcing the seal with supplementary methods like nails or screws may be necessary.

- Q: Can packaging tape be used on different materials?

- Yes, packaging tape can be used on different materials. Packaging tape is versatile and can adhere to a wide range of surfaces, including cardboard, plastic, metal, glass, and even fabric. It is designed to provide a strong and secure seal, ensuring that packages remain intact during transportation and storage. Whether you are sealing a cardboard box, bundling items together, or securing a package, packaging tape is an effective choice for various materials.

- Q: Can packaging tape be used for sealing poly mailers?

- Yes, packaging tape can be used for sealing poly mailers. Packaging tape is commonly used to seal a variety of packaging materials, including poly mailers. It provides a strong and secure seal that prevents the contents from falling out or being tampered with during transit. However, it is important to ensure that the tape is applied properly and securely to ensure the integrity of the seal. Additionally, it is recommended to use a high-quality packaging tape that is designed for secure sealing to ensure the best results.

- Q: How does packaging tape perform on fabric or textile surfaces?

- Packaging tape generally adheres well to fabric or textile surfaces, providing a strong bond. However, its effectiveness may vary depending on the type and texture of the fabric. It is recommended to test a small area before applying packaging tape to ensure it does not damage or leave residue on the fabric.

- Q: What are the benefits of using tamper-evident packaging tape?

- Tamper-evident packaging tape offers several benefits, including enhanced security and protection of goods during transit. It provides a clear indication if the package has been tampered with, ensuring the integrity of the contents. This not only helps prevent theft and unauthorized access but also increases customer confidence in the product. Additionally, tamper-evident tape acts as a deterrent, discouraging potential tampering or pilferage. Overall, it offers peace of mind, improved product safety, and a reliable way to maintain the authenticity of packaged items.

- Q: Is packaging tape safe to use on mirrors?

- Yes, packaging tape is safe to use on mirrors as it adheres well without causing any damage or leaving residue behind when removed.

- Q: How does packaging tape perform on low-friction surfaces?

- On low-friction surfaces, such as smooth plastics or certain laminates, packaging tape tends to underperform. These surfaces lack texture and adhesion, posing difficulties for the tape to adhere and hold effectively. Due to the absence of friction, the tape easily slides or peels off, putting the package's integrity at risk. To overcome this issue, it is recommended to utilize alternative techniques like shrink wrapping, heat sealing, or adhesive sprays specially formulated for low-friction surfaces. These alternatives offer superior adhesion and guarantee secure sealing throughout handling and transportation.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | Southeast Asia; South America; Eastern Europe; North America; Northern Europe; South Asia; Western Europe; Africa; Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | 10%-20% |

| No.of Employees in Trade Department | 51-100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | masking tape, cloth tape, PET tape |

| Product Price Range | Average |

Send your message to us

Fiberglass Tape FGT-180 - Packaging Tape Melbourne

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1x20' FCL roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords