Composite Fiberglass Reinforced Plastic (FRP/GRP) Pipes API Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pipe Description

Made from the high quality corrosion resistant resin and continuous fiber winding without alkali, filament winding FRP pipe possesses the characteristics of lightness, high strength, distinguished corrosion resistance and expedient installation and maintenance etc.,

FRP Pipes were applied widely in the oil-field system of sewage treatment, electrical plant water circulation, water pipe with electric magma and projects of chemical engineering, metallurgy, and medicine processing etc.

our company (headquarter in Jiangsu Province) has been the No. 1 in exporting composites products domestically, annual capability of 100,000 tons for pipes & tanks as well as 10,000 pieces of wind turbine blade, with branches in Thuringia of Germany, Liaoning province, Neimenggu Province, Gansu Province, Xinjiang Province and Sichuan Province etc.

We are the exclusive FRP manufacturer with rich experiences in cooperating with foreign companies worldwide, the only supplier that provides large-diameter FRP pipes to the nuclear power station. Sole company owning finite element analysis in China. 20 production lines are in good operation.

Main Features of the FRP Pipe

Corrosion-resistant

Light weight

Long standard lengths

Extremely smooth bore

Precision sealability

Flexible manufacturing

High technology pipe design

High technology pipe manufacturing system producing pipe that complies to stringent performance standards (AWWA, ASTM, DIN, EN,BS, etc.)

FRP Pipe Application

1)drinking water transmiting

2)sewage pipeline,rainwater pipelin

3)angricultural irrigation

4)seawater desalination system

5) other kinds of liquid transmiting

6)municipal engineering construction

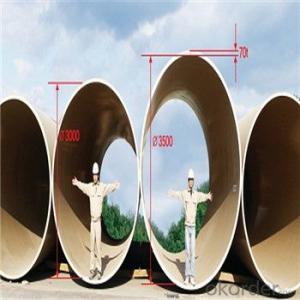

FRP Pipe Images

FRP Pipe Specification

Diameter: DN300-4000

Pressure:PN6-25

Standard length: 6m, 12m

Execute standard:JC552,ASTMD2996

Management System & Certificates

Management system: ISO9001, ISO14001, OHSAS18001,

Performance standards: ASTM D3262, D3517, D3754/AWWA C950, M-54/China Standard B/21238, JC552, CECS190, CECS129; DIN16868/ BS 5480;

WRAS Certificate, API Certificate, Installation Qualification.

Caesar II is applied for stress analyzing of piping system, AFT impulse is used for analysis of water hammer. Meanwhile we can supply finite element analysis to the customer.

FAQ of FRP Pipe

Q: What is fiberglass composite?

A: Fiberglass composite is a laminate made from glass fibers or filaments and thermosetting resin. It is commonly known as RTRP, RTMP, FRP, GRP, GRE and GRV.

Q: Are fiberglass pipes fragile?

A: Due to the elastic nature of the resin which holds the clothlike glass fibers together, fiberglass is strong and flexible. FPI products meet the rigorous "Impact Test" requirements of the international standard e.g. BS, API, ...

Q: What is the trade information

A: Trade terms:FOB,CIF,EXW

Payment terms:T/T,L/C

Shipping:By sea,by air and by express delivery

- Q: Winding method of glass fibre reinforced plastic pipeline anticorrosive glass fiber cloth

- 1) first, apply the release agent on the molding surface of the glass lined sand pipe mold (or a transparent cellophane on the outer surface of the mold);2) after sufficient drying, the magnesium oxychloride cement with initiator (or curing agent), accelerant and other additives is evenly coated on the molding surface of the die;3) then put a good glass cloth on the glass lined sand pipe;4) then apply the magnesium oxychloride cement on the paved glass cloth and take care to remove the bubbles.5) with good magnesium oxychloride cement paste then with cut glass cloth;6) repeat this operation until the GRP sand pipe reaches the design and gauge thickness.

- Q: Are FRP pipes still developing?

- I graduated last year and like you, stay two months left, glass steel pipeline buried pipe still have comparative advantages, but in Chinese, the quality of the products before this, after all, as the steel pipe is reliable, now doing chemical, water treatment, rarely encountered glass steel pipes, steel pipes generally do not. PVC, most used, the cost is much lower than the glass steel

- Q: What are the disadvantages of glass fiber reinforced sand pipe?

- In brief, the disadvantage of FRP sand pipe is that the pipe is restrained by external environment, such as construction environment and span of support. Used in drinking water engineering, loess and sandy soil in the north are more suitable, but in ponds, marshes, mountains, then the pipeline backfill will increase the project investment. Used for overhead glass steel pipe lines, supporting the size of the gap is also the success or failure of the pipeline.

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- Usually with aluminum or iron sheet, with glass or steel, or the first time, I'm afraid the toughness is not enough.

- Q: Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- The use of a fixed fare set without further consideration to duct losses has been included in the quota project

- Q: What is the difference between glass tube, sand pipe and glass tube?

- Glass reinforced plastic sand pipe is actually in the production of glass fiber reinforced plastic pipe, in the middle to increase a layer of sand layer, the purpose is to increase the rigidity of the pipeline.

- Q: Pipe installation of glass fibre reinforced plastic pipe

- In the area, pipeline installation order system, small diameter and large diameter after the first, the first layer after layer, the first easy, first on the pipe rack even after the equipment, pipeline is connected with the machine principle is from the inside to the outside, in order to reduce the influence of welding stress on the installation precision of the machine, touch the mouth interior with the outdoor pipeline should stay outside.

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- PE bellows is good, and now they are so connected.

- Q: What is the thickness of all types of FRP pipes?

- DN200, DN150, DN100, DN80 pipe, polyurethane foam pad, 50mm thick shell, glass steel, thickness 3mm.

- Q: What are the posts of glass fiber reinforced plastic sand pipe and the corresponding occupational hazards and protection?

- FRP material has the characteristics of excellent corrosion resistance, no underground water or sewage pipe tube with acidic or alkaline causes no damage to the use of the product, and the product itself, do not need to do any protective measures, steel pipe and concrete pipe does not have the advantage.

Send your message to us

Composite Fiberglass Reinforced Plastic (FRP/GRP) Pipes API Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords