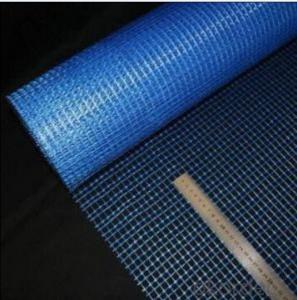

Fiberglass Mesh Grating, 135 gram/m2, Blue Colour Fiber Glass Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Fiber Glass Mesh, 135 Gram/m2, Blue Colour

FOB Price of Fiber Glass Mesh, 135 Gram/m2, Blue ColourUS $0.28 / Square Meter

MOQ of Fiber Glass Mesh, 135 Gram/m2, Blue Colour : 5000 Square Meters

Supply Ability of Fiber Glass Mesh, 135 Gram/m2, Blue Colour: 6000000 Square Meters per Month

Payment Terms of Fiber Glass Mesh, 135 Gram/m2, Blue Colour: L/C,T/T

Fiber Glass Mesh, 135 Gram/m2, Blue Colour

Specifications of Fiber Glass Mesh, 135 Gram/m2, Blue Colour

Fiber Glass Mesh, 135 Gram/m2, Blue Colour Application: Wall Materials

Fiber Glass Mesh, 135 Gram/m2, Blue Colour Width: 1M-2M

Fiber Glass Mesh, 135 Gram/m2, Blue Colour Size: 5*5/ INCH

Fiber Glass Mesh, 135 Gram/m2, Blue Colour Weight: 40gsm to 200gsm

Fiber Glass Mesh, 135 Gram/m2, Blue Colour Weave Type: Plain Woven

Fiber Glass Mesh, 135 Gram/m2, Blue Colour Yarn Type: C-Glass

Fiber Glass Mesh, 135 Gram/m2, Blue Colour Alkali Content: Medium

Fiber Glass Mesh, 135 Gram/m2, Blue Colour Standing Temperature: 500℃

Product information of Fiber Glass Mesh, 135 Gram/m2, Blue Colour

Name: Fiber Glass Mesh, 135 Gram/m2, Blue Colour

Use best fiberglass yarn and best glue

Clear and beautiful Fiber Glass Mesh, 135 Gram/m2, Blue Colour

High strength Fiber Glass Mesh, 135 Gram/m2, Blue Colour

30 years experience of manufacturing Fiber Glass Mesh, 135 Gram/m2, Blue Colour

Excellent Priced Fiber Glass Mesh, 135 Gram/m2, Blue Colour

FAQ of Fiber Glass Mesh, 135 Gram/m2, Blue Colour

Q: What is Fiber Glass Mesh, 135 Gram/m2, Blue Colour?

Coated Alkali-resistant Fiber Glass Mesh, 135 Gram/m2, Blue Colour is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Fiber Glass Mesh, 135 Gram/m2, Blue Colour?

Weight: 135g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of Fiber Glass Mesh, 135 Gram/m2, Blue Colour?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of Fiber Glass Mesh, 135 Gram/m2, Blue Colour?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Fiber Glass Mesh, 135 Gram/m2, Blue Colour?

Four years under normal weather conditions and use .

Q: What is the package of Fiber Glass Mesh, 135 Gram/m2, Blue Colour?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Fiber Glass Mesh, 135 Gram/m2, Blue Colour?

Production periods: 30days for 1X40HQ.

- Q: Function of fiber net in building plastering

- Because two kinds of wall materials because of the expansion rate is not always, will produce cracks, such as concrete wall and brick wall, and fiber network in two kinds of material surface, thereby reducing the generation of this crack.

- Q: What is the difference between different glass fiber mesh cloth

- A general glass fiber mesh cloth roll at both ends, both ends of blue green is non alkali glass fiber products

- Q: How to paste gridding cloth?

- Gridding cloth is a material used for for metope grassroots anti-cracking material in home decoration. It is also called crack resistant cloth, crack resistant gridding cloth and generally made of fiberglass. In construction, cloth is used for crack instead of crack resistant cloth.

- Q: Fiberglass mesh warp and weft, which one is more resistant to fracture?

- After alkaline polymer, this is not entirely the key to judging the quality of products. For the majority of consumers, quality is the most important. In order to better play the efficacy of products, it is made from middle-alkaline or non-alkialine glass fiber.

- Q: The introduction to alkali-resistant glass fiber mesh cloth

- Alkali-resistant fiberglass mesh alkali or alkali glass fiber woven fabric is based by alkali-resistant coating, the product is excellent in strength, adhesion, docile nature, positioning, which is widely used in enhanced wall and thermal insulation and waterproof of external wall.

- Q: Are epoxy resins and glass fibers the same kind of thing?

- Epoxy resins refer to organic compounds containing two or more epoxy groups in the molecule. Except for some of them, the relative molecular weight of them is not high enough. (two). The molecular structure of epoxy resin is characterized by the presence of active epoxy groups in the molecular chain. The epoxy group can be located at the end of the molecular chain, intermediate or ring like structure. Because the molecular structure contains active epoxy groups, they can react with various types of curing agents to form insoluble polymers with three directions network structure. Any polymer compound with epoxy groups in its molecular structure is collectively referred to as an epoxy resin.

- Q: The house is hollowing in some parts at present. If you want to install mesh, is there a need to repair the hollowing parts?

- Not need. The contents of the room inspection 1. The inspection of wall, roof and floor is mainly to check the hollowing which has direct effect on the decoration cost later. If there are any problem, the developers are in charge of repairing. The hollowing of the wall can cause the cracking and loss in the later period. The hollowing of the floor will lead to the fracture of the floor tile. The loose of the wood floor will produce noise. For the fissure of the wall, it generally not require to be repaired by the developers. It is generally handled by the decoration company. If there are any doubt about the structure, you should consult the professionals. 2. The acceptance inspection of the doors and windows mainly depends on the appearance quality, such as: The damage, bump and scratch of the frame. If the damage of the frame is very difficult to be repaired as good as the original one, it should be replaced. The qualified scratch of the glass should be 0.1cm width and10cm length, and the quality of the hollowed glass should be also noticed, especialy in winter when the interior surface of the glass is with water. 3. The inspection of the electrical parts is mainly to check the power supply. The weak electricity that did not open cannot be checked. The electrical socket outlet should be correct and should not be on the contrary. The ground connection wire should be paid the most importance, if without, the reason should be found out. 4. The inspection of the equipment should be checked by the developers or the real estates. After being teached how to use, the owners can operate by themselves.

- Q: If external insulation material is insulation putty, is it necessary to wrap external corners of mesh?

- Before being paving, mesh shoule be scraped a leveling blamket with cracking resistant mortar on insulation layer. Then paste mesh, slightly press it with trowel, and scrape another cracking resistant mortar to make sure that mesh is outside of the cracking resistant mortar so that it is crack-resistant.

- Q: What is the difference between medium alkali glass fiber cloth and alkali resistant glass fiber cloth?

- As for the cloth and mesh cloth, just different weave, has nothing to do with the glass composition.

- Q: How to paste reinforced mesh into the reverse side of stone?

- Use epoxy resin to paste stone, then dry mesh and use epoxy resin with curing agent to brush finish.

Send your message to us

Fiberglass Mesh Grating, 135 gram/m2, Blue Colour Fiber Glass Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords