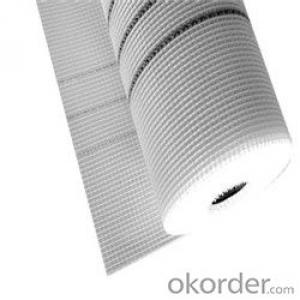

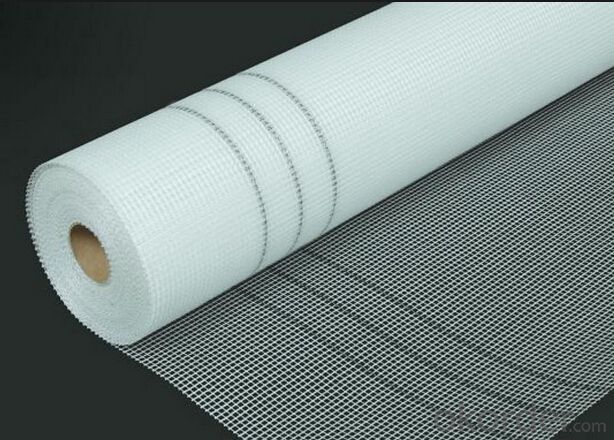

Fiberglass Mesh Cloth - Coated Alkali-Resistant Fiberglass Mesh Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Coated Alkali-Resistent Fiberglass Mesh Cloth

Product Description:

Fiberglass Mesh is made of quality filamentary plastic coating glass fiber yarn by special weaving technique. Fiberglass Mesh has plain and neat appearance, good season-fitting, steady and soft color. Fiberglass Mesh is the first choice for home, hotel and offices to prevent sunshine.

Fiberglass Mesh are mainly used in construction and decoration. Fiberglass Mesh has the properties of alkali-resistance and high tensile strength. This will bring people a comfortable feeling and comfortable life.

Specifications:

1. Standard Mesh: 3mm× 3mm, 4mm× 4mm, 5mm× 5mm, 6mm× 6mm, 10mm× 10mm.

2. Weight/m2: 50g - 300g.

3. Length/Roll: 50m - 300m.

4. Width/Roll: 0.2m - 2m.

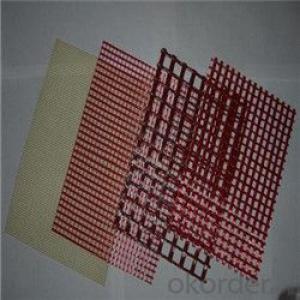

5. Standard Color: White(standard), blue, green or other colors.

6. Packing: Each roll shrank wrapped, then by carton.

7. Special items can also be done as per customers' requirements.

| 1 | Mesh size: | 5x5mm, 4x5mm or 4x4mm; |

| 2 | Weight: | 80g- -160g; |

| 3 | Length/roll: | 50m, 100m or 200m; |

| 4 | Width/roll: | 1m- -2m; |

| 5 | Colours: | White(standard), blue, green or other colors. |

| 6 | Packing: | Each roll shrank wrapped, four or six rolls a carton; A 40ft container can be loaded about 80, 000- -150, 000 square meters. |

| 7 | Special items can also be done if some changes on weight, width, length, color, or packing if required by customers | |

FAQ of Fiberglass Mesh

Q: What is Fiberglass Mesh?

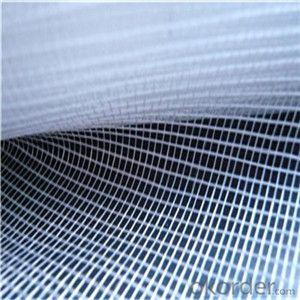

Coated Alkali-resistant Fiberglass Mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Fiberglass Mesh?

Weight: 40gsm to 200gsm

Width: 1M--2M

Length: 20m, 50m, 100m

Q: What is the application of Fiberglass Mesh?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of Fiberglass Mesh?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Fiberglass Mesh?

Four years under normal weather conditions and use .

Q: What is the package of Fiberglass Mesh?

Package: rolls are packed into cartons or pallets.

Packing volumes: about 10000m/20FCP, 20000m2/40HQ.

Q: Wow long about the production periods of Fiberglass Mesh?

Production periods: 30days for 1X40HQ.

- Q: What's the use of fiberglass mesh?

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion. Therefore, the utility model has the advantages of good alkali resistance, flexibility, and high tensile resistance at warp and weft direction. The utility model can be widely used for heat preservation, water resistance and crack resistance of walls inside and outside buildings.

- Q: The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- Grid cloth stereotypes are used in the market, a wide range of species, can generally be divided into urine gel, latex twoThe grid cloth made of urine gum is hard, and the quality of latex is almost worse than that of latex

- Q: Glass fiber mesh cloth bent do to straighten it?

- Of course not, because of hard and soft and orientation relationship, different product positioning different soft and hard to do it, and a product is related to raw materials, and then coated on the surface of the adhesive is below, introduced from two aspects respectively.

- Q: What is the function of the wall cloth mesh?

- The main uses are widely used:1) wall reinforcement materials (such as glass fiber wall, net cloth, GRC wallboard, EPS internal and external wall insulation board, gypsum board and so on.2) reinforce cement products (such as Rome column, flue, etc.).3) granite, mosaics, special mesh, marble back net.4) waterproof coiled material and bituminous roof waterproof.5) strengthen the skeleton material of plastic and rubber products.

- Q: Self-adhesive fiberglass mesh

- EPS mesh made of alkali resistant glass fiber fabric, it uses alkali free glass fiber yarn by weaving leno weave structure and special organization, after the anti alkali, heat setting treatment such as reinforcing agent, finally by not dry glue coating baked. A EPS mesh fabric with alkali resistance, softness, adhesion and tensile resistance is formed.

- Q: Glass fiber mesh cloth, pure gold pot with what glue out, finished products can be detected, as well as the proportion of glue is how much?

- This product and people engaged in the industry of external wall insulation pot imitation gold mesh fabric is very familiar, but exactly how this product is really not much here to explain imitation gold mesh pot is to be defined.

- Q: What are the fiberglass mesh fabric manufacturers?

- Offiberglass self-adhesive caulkingGlass fiber self-adhesive tapes are made from high quality glass fiber fabric coated with acrylic copolymer, which is stable and difficult to oxygen because of its chemical propertiesSo, we developed production offiberglass self-adhesive caulking is not only superior to other similar products There is nothing comparable to this.

- Q: What's the price of fiberglass mesh?

- Alkali resistant glass fiber mesh cloth big price difference, and the alkali resistant glass fiber mesh quality, tensile strength

- Q: Slotted walls, seams, seams, tape, or anti mesh cloth?

- Don't spend so much money to buy what tape and mesh cloth, is decorated well, to buy the cheapest dacron, remember to not want that kind of chemical fiber, cotton, cotton for a long time to decay.

- Q: What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- How to identify quality problems of alkali resistant glass fiber cloth, glass fiber cloth market price of 1. of the worst is usually around 1 yuan -1.60 yuan, his glass fiber is usually made of some kind of waste glass beer bottles, the production process for clay crucible drawing, production process is prohibited by the state, the surface coating is non alkali resistant emulsion. From the intuitive point of view: the work is relatively rough, generally sold in the market volume of the theory, often lack of length, grams of weight is not enough, two fold on the break, the contact is not firm, easy to shift, and easy to stab the skin. In the insulation layer in general in the two months after the loss of strength using the grid cloth, if the mortar off grid cloth out, just gently crushed, fiberglass yarn is made into powder.

Send your message to us

Fiberglass Mesh Cloth - Coated Alkali-Resistant Fiberglass Mesh Cloth

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords