Fiberglass Mat Tissue E Glass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 240000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

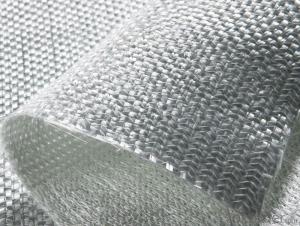

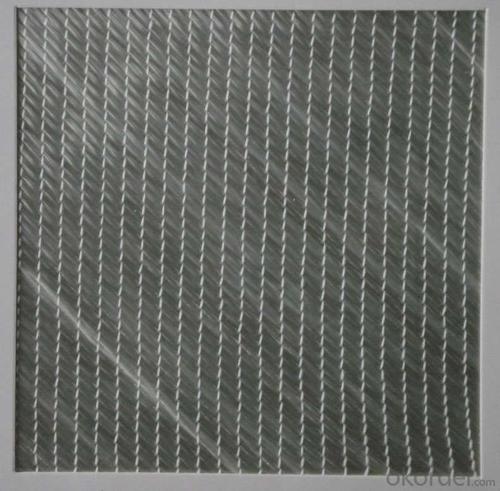

1.Brief Introduction

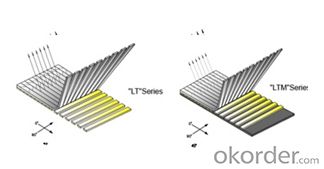

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-UDL450 | 479.14 | 405.66 | 55.12 | - | 18.36 |

E-UDL500 | 490.85 | 405.66 | 66.83 | - | 18.36 |

E-UDL600 | 608.9 | 566.92 | 23.62 | - | 18.36 |

E-UDL1200 | 1207.34 | 1133.86 | 55.12 | - | 18.36 |

Special specification can be produce according to customer requirements.

4.FAQ

a.Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

b.Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Can fiberglass mat tissue be used for flooring insulation?

- Typically, fiberglass mat tissue is not employed for flooring insulation. It is a lightweight substance frequently utilized in the construction sector to reinforce plaster and concrete, and as insulation in walls and ceilings. However, for flooring insulation purposes, other materials like foam boards or batt insulation are generally favored. These materials offer superior thermal and sound insulation features that are specifically tailored for flooring applications. Moreover, they are simpler to install and better equipped to endure the pressures and demands of foot traffic on the flooring.

- Q: How does fiberglass mat tissue perform in high temperatures?

- Fiberglass mat tissue performs well in high temperatures as it has a high melting point and excellent heat resistance. It retains its strength and structural integrity even when exposed to elevated temperatures, making it suitable for various applications in high-temperature environments.

- Q: Does fiberglass mat tissue require any special maintenance after installation?

- Once the fiberglass mat tissue is installed, it typically requires no special maintenance. Its design makes it durable and resistant to wear and tear, as well as highly resistant to moisture, chemicals, and UV radiation. This versatility makes it suitable for a variety of applications, such as roofing, insulation, and wall covering. However, it is advisable to periodically inspect the fiberglass mat tissue to guarantee its good condition. This involves checking for any indications of damage, such as cracks, tears, or delamination. In the event of any issues, prompt attention should be given to prevent further harm. Furthermore, it is essential to adhere to the manufacturer's guidelines and recommendations concerning the specific type of fiberglass mat tissue used. This may involve avoiding exposure to certain chemicals or utilizing appropriate cleaning methods if necessary. In summary, while fiberglass mat tissue generally requires minimal upkeep, regular inspections and adherence to the manufacturer's instructions can promote its durability and optimal functionality.

- Q: Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a versatile material that is commonly used in various insulation applications due to its excellent thermal insulation properties. It is lightweight, flexible, and provides effective insulation against heat transfer. When used in insulation jackets, fiberglass mat tissue can help to retain heat and prevent heat loss, making it an ideal choice for applications where thermal insulation is required. Additionally, fiberglass mat tissue is also fire-resistant, which further enhances its suitability for insulation jackets.

- Q: How does fiberglass mat tissue perform in terms of thermal expansion?

- Fiberglass mat tissue has a relatively low thermal expansion coefficient, meaning it expands minimally when exposed to heat. This characteristic makes it an excellent material for applications where thermal stability is crucial. The tightly woven structure of fiberglass mat tissue helps to limit the expansion and contraction of the material, even under high temperatures. Consequently, it exhibits excellent dimensional stability and resistance to thermal stresses. This property allows fiberglass mat tissue to maintain its structural integrity when exposed to extreme temperature variations, making it highly suitable for use in industries such as aerospace, automotive, and construction, where thermal expansion and contraction can pose significant challenges.

- Q: Is fiberglass mat tissue suitable for construction applications?

- Indeed, fiberglass mat tissue proves to be a fitting material for construction purposes. Renowned for its robustness, longevity, and ability to withstand diverse environmental conditions, this versatile substance is frequently employed in roofing, flooring, insulation, and wall panel installations. Fiberglass mat tissue emerges as an exceptional selection for construction ventures as it bestows reinforcement and stability upon a range of materials. When incorporated into roofing materials, it fortifies them against impacts, weathering, and fires. Similarly, it bolsters the strength and durability of flooring systems, rendering them capable of withstanding substantial loads and heavy foot traffic. Moreover, fiberglass mat tissue exhibits commendable insulation capabilities. It serves as an efficacious insulating component for walls, ceilings, and floors, enabling the maintenance of a comfortable indoor temperature while diminishing energy consumption. Its thermal and acoustic insulation properties render it an ideal choice for construction applications. Furthermore, its imperviousness to moisture, chemicals, and corrosion makes fiberglass mat tissue a suitable option for deployment in areas characterized by high humidity or exposure to harsh chemicals. Thanks to its resistance to decay, it guarantees durability, ensuring longevity in construction projects. To conclude, fiberglass mat tissue is an apt choice for construction applications due to its strength, durability, insulation properties, and resistance to various environmental factors. Its adaptability and reliability have cemented its popularity within the construction industry.

- Q: What is the shelf life of fiberglass mat tissue?

- The shelf life of fiberglass mat tissue can vary depending on several factors such as storage conditions, packaging, and the specific manufacturer's recommendations. Generally, fiberglass mat tissue can have a shelf life of around one to two years if stored in a cool, dry place and unopened. However, it is important to note that over time, the material may degrade or lose its physical properties, which can affect its performance and suitability for use. Therefore, it is advisable to always check the manufacturer's guidelines or consult with them directly for the most accurate information regarding the shelf life of a particular fiberglass mat tissue product.

- Q: Can fiberglass mat tissue be used for reinforcement in composites?

- Yes, fiberglass mat tissue can be used for reinforcement in composites. It is commonly used as a reinforcement material in various composite applications due to its high strength, durability, and excellent bonding properties. The fiberglass mat tissue helps enhance the mechanical properties and structural integrity of the composite material.

- Q: Can fiberglass mat tissue be used for insulation in hot climates?

- Yes, fiberglass mat tissue can be used for insulation in hot climates. It has excellent thermal insulation properties and can effectively block heat transfer, making it suitable for use in hot climates to maintain cooler indoor temperatures.

- Q: Can fiberglass mat tissue be used for reinforcing concrete?

- Indeed, reinforcing concrete is possible with the utilization of fiberglass mat tissue. This lightweight and flexible material is frequently employed in construction endeavors to augment the sturdiness and endurance of concrete structures. By embedding it within the concrete, additional reinforcement is provided, which aids in averting the formation of cracks over time. Typically crafted from top-notch glass fibers that are interwoven to form a robust and steady substance, fiberglass mat tissue showcases exceptional tensile strength and corrosion resistance, rendering it an optimal selection for enhancing the performance of concrete. Whether employed in sidewalks, driveways, or other concrete formations, the presence of fiberglass mat tissue can substantially heighten the potency and lifespan of the concrete in question.

Send your message to us

Fiberglass Mat Tissue E Glass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 240000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords