Fiberglass Insulation Sleeve PVC Fiberglass Insulation Sleeving 2.5kv-in002

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 5000000METER/MONTH m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

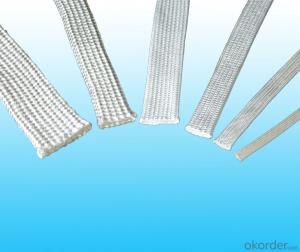

Product Description of PVC Fiberglass Insulation Sleeving 2.5KV:

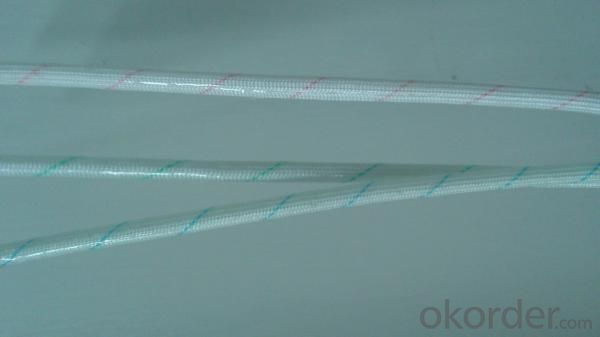

Diameter:0.5mm~30mm

Breakdown Voltage:2.5KV,

Colour: red line, green line, blue line and all kinds of color

Usage/Applications of PVC Fiberglass Insulation Sleeving 2.5KV

PVC fiberglass sleeving is fiberglass sleeving coated with PVC resin, with very good flexibility and dielectric features, it is widely used as insulating and protection material for motor and electric appliance.

Packaging & Delivery of PVC Fiberglass Insulation Sleeving 2.5KV

Production Line of PVC Fiberglass Insulation Sleeving 2.5KV

- Q: What are the uses of glass fiber reinforced plastics?

- Construction industry: cooling tower, glass steel doors and windows New, building structure, building envelope, interior decoration, equipment and glass steel plate, corrugated tile, decorative panels, sanitary ware and bathroom, sauna, surfing the whole bathroom, construction formwork, storage building, concrete formwork, reinforcement, and solar energy utilization device etc..

- Q: What are the manufacturers of high temperature sleeving (fiberglass, silicone sleeve)?

- Single glass fiber casing (MBQGD) using alkali free glass fiber yarn, after coated with silicone resin, then through high temperature drying and shaping material. Products with heat resistance, corrosion resistance, anti aging characteristics, softness, and can play a good role in insulation. A major application of high temperature, products high voltage, transformer, generator, engine, electric equipment, household appliances and lighting and other industries, to provide insulation protection. ,

- Q: What are fiberglass tubes, and what are they mainly used for?

- Motor winding joints, electric mattress, rice meal fort, electric iron, general electric heating equipment, almost all used.

- Q: What is the difference between a thermally conductive insulating sheet and a thermally conductive silicon film?

- The heat conduction insulating sheet and the heat conducting silica gel sheet are both heat conducting and insulating materials.

- Q: What are the materials used for the insulation breakdown of high voltage cables?

- Insulated pipe is a general term. A glass fiber insulation casing, PVC casing, heat shrinkable sleeve, Teflon sleeve, ceramic sleeve etc..

- Q: LED fluorescent tube, with glass fiber board, or with aluminum substrate, okay?

- Aluminum substrate is mainly good heat dissipation, whether the equipment life or use effect is good, high costGlass fiber fiber plate compared to the aluminum substrate, heat dissipation is too bad, cheap

- Q: What is a high temperature resistant insulated fire protection sleeve?

- Characteristics and application:1. safety protection to protect the health of the workersAlkali free glass fiber itself has very strong tension characteristics, will not wrinkle broken, anti sulfuration, smokeless halogen-free non-toxic, pure oxygen combustion, good insulation, followed by organic silica gel after curing, strengthens its safety and environmental protection, effective protection of workers health, reduce the incidence of occupation disease. Unlike asbestos products, they are extremely hazardous to the human body and the environment.2. superior performanceThe organosilicon structure on the surface of the casing contains both organic groups and inorganic structures. This particular composition and molecular structure make it characteristic of organic compounds and inorganic compounds. Compared with other polymer materials, the most prominent is its high temperature resistance. The silicon oxygen bond (SiO) as the main chain structure, C-C bond is 82 thousand and 600 kcal / mole, SiO bond card / 121 thousand in silicon molar, so its high thermal stability, high temperature (or radiation) molecular bond doesn't break, do not break down. Silicone is not only resistant to high temperature and low temperature resistance, can be used in a wide temperature range. Both chemical properties and physical and mechanical properties vary little with temperature.

- Q: Why should transformer coils be graded insulated?

- According to use can be divided into: power transformers and special transformers (electric furnace transformer, rectifier transformer, power frequency test transformer, voltage regulator, mine, variable audio transformers, intermediate frequency transformers, high frequency transformer, transformer, instrument transformer, the impact of electronic transformer, reactor, transformer etc.). Circuit symbols are often used as the beginning of numbers. Examples: T01, T201, T, etc..

- Q: How to distinguish between fiberglass cloth coated with silica gel?

- Main properties and characteristics of silicone rubber fiber glass cloth:(1) for low temperature -70 DEG C to high temperature 280 DEG C, good thermal insulation property.(2) ozone resistance, oxygen, light and climate aging, field use, good weather resistance, life expectancy of up to 10 years.(3) high dielectric properties, dielectric constant 3-3.2, breakdown voltage 20-50KV/MM.(4) resistance to chemical corrosion is good; oil resistance, waterproof [scrub].(5) high strength, soft and tough, and can be cut and processed.

- Q: Where is the best ceramic fiber packing?

- Compared with asbestos textiles, ceramic fiber textiles have the following advantages:1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Insulation Sleeve PVC Fiberglass Insulation Sleeving 2.5kv-in002

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 5000000METER/MONTH m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords