Extruded Anodes AZ61D of Magnesium Upon Customer's Require

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Extruded Sacrificial Anodes of Magnesium Upon Customer's Require

1. Specification:

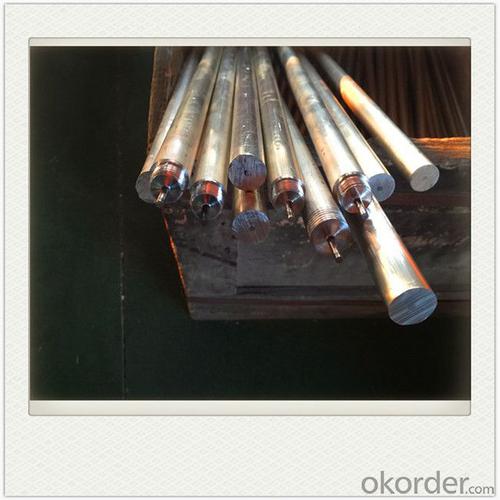

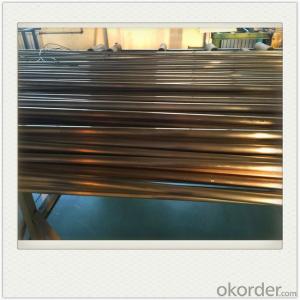

We are capable of manufacturing all kinds of extruded sacrificial anodes of magnesium and aluminum alloys upon customer's requirements. Compared with casting magnesium rod, is capable of producing all kinds of extruded magnesium and aluminum alloy sacrificial anode upon customer's requirement. Compared with cast magnesium rods, extruded magnesium rod has a better machining accuracy and a finer surface finish, and provides the most effective protection for the product it is installed in.

2. Application:

Being an important type of sacrificial anodes of magnesium alloys, extruded sacrificial anodes of magnesium are mainly applied in water heaters, heat exchangers, evaporimeters, boilers and other equipment. They soften water, remove dirt and therefore extend the service life of machines.

3. Images

4. Advantages:

Good Quality ............... The most important factor we care.

Competitive Price ........ For our mutual benefit.

Prompt delivery ........... Abundant production ability, storage ability and manpower.

Excellent Service ......... Customer always first.

Now our main markets in Asia and Europe, to the future we will set up sales network in more than 200 countries around the world.

5. What is Magnesium Alloys?

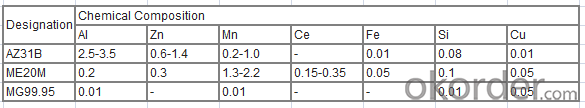

Magnesium alloys are mixtures of magnesium with other metals (called an alloy), often aluminum, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium is the lightest structural metal. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles, and magnesium block engines have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

Practically, all the commercial magnesium alloys manufactured in the United States contain aluminum (3 to 13 percent) and manganese (0.1 to 0.4 percent). Many also contain zinc (0.5 to 3 percent) and some are hardenable by heat treatment. All the alloys may be used for more than one product form, but alloys AZ63 and AZ92 are most used for sand castings, AZ91 for die castings, and AZ92 generally employed for permanent mold castings (while AZ63 and A10 are sometimes also used in the latter application as well). For forgings, AZ61 is most used, and here alloy M1 is employed where low strength is required and AZ80 for highest strength. For extrusions, a wide range of shapes, bars, and tubes are made from M1 alloy where low strength suffices or where welding to M1 castings is planned. Alloys AZ31, AZ61 and AZ80 are employed for extrusions in the order named, where increase in strength justifies their increased relative costs.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

CNBM, The Fortune 500. A world class manufacturer & supplier of magnesium alloys ingots plates&sheets, magnesium alloy bars, Magnesium alloy slabs,magnesium alloy wires,magnesium alloy tubes and etc.. bases in China.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;

We would like to offer free samples for your inspect and check.

We have advanced manufactured equipments,such as hot rolling equipment. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③What is your main markets?

Our main markets are from Europ, America and Aisa. Such as Germany,Czech, Poland, England, Canada, Korea, Turke

Send your message to us

Extruded Anodes AZ61D of Magnesium Upon Customer's Require

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches