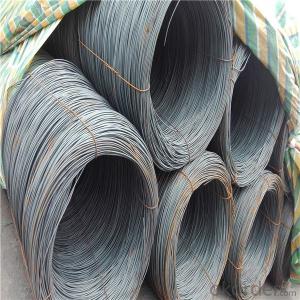

Export steel wire rod from China in different grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 12984 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Drawing Grade wire rods are used by downstream industries for various applications such as making wires for

welded mesh, nails, hangers, screws, chain link & gabion fencing, wire nets, barbed wires and binding wires.

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale,

easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

It generally used in braiding the hose for bathing product and machinery. With it

good flexibility, resistant to high temperature and resistant to corrosion, it

used widely in many industries.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the different types of steel used for manufacturing wire rod?

- There are several different types of steel used for manufacturing wire rod, including low carbon steel, high carbon steel, alloy steel, and stainless steel. Each type of steel has its own unique properties and characteristics, making it suitable for specific applications and industries. Low carbon steel is commonly used for general-purpose wire rod, while high carbon steel is used for applications requiring high strength and durability. Alloy steel is used when additional properties such as heat resistance or corrosion resistance are required. Stainless steel, on the other hand, is used for applications that require excellent corrosion resistance, such as in the automotive or construction industry.

- Q: How is steel wire rod used in the automotive industry?

- Steel wire rod is used in the automotive industry for various applications such as manufacturing engine components, suspension systems, and safety features like seat belts and airbags. It is also used in the production of tires, as reinforcement for rubber hoses, and in the construction of vehicle frames and bodies. The high strength and durability of steel wire rod make it a preferred material choice in the automotive sector, ensuring safety and reliability in vehicles.

- Q: How is steel wire rod used in the production of wire screens?

- Steel wire rod is used in the production of wire screens as it serves as the primary material for creating the screen mesh. The wire rod is drawn through a series of dies to achieve the desired diameter and strength. This process results in a long, continuous piece of wire that can be woven or welded to create the wire mesh for screens. The steel wire rod's durability and flexibility make it an ideal choice for wire screens, ensuring a strong and reliable product for various applications such as filtration, separation, and protection.

- Q: What are the different types of steel wire rod surface defect prevention techniques?

- Some of the different types of steel wire rod surface defect prevention techniques include surface cleaning and descaling, mechanical removal of defects, surface coating or plating, and proper handling and storage practices.

- Q: How is the dimensional accuracy of steel wire rod ensured?

- To ensure the dimensional accuracy of steel wire rod, a series of manufacturing and quality control processes are implemented. Initially, the wire rod is produced using continuous casting or hot rolling methods, closely monitoring and controlling the dimensions. This ensures that the wire rod's diameter and shape fall within the desired tolerances. After formation, the wire rod is subjected to various mechanical treatments such as drawing, annealing, and cooling. These processes further refine the dimensions and enhance the mechanical properties of the wire rod. Drawing involves pulling the wire rod through progressively smaller dies, achieving the desired diameter with utmost precision. Throughout the manufacturing process, regular inspections and measurements are conducted to guarantee the dimensional accuracy of the wire rod. Advanced measurement techniques, such as laser-based measuring systems or optical scanners, are utilized to assess the diameter, roundness, and surface quality of the wire rod. Moreover, quality control procedures are implemented to ensure adherence to the required dimensional standards. Samples are taken at regular intervals, and their dimensions are measured to verify compliance with specified tolerances. Any deviations from the desired dimensions are identified, and appropriate corrective actions are taken to maintain dimensional accuracy. In conclusion, the dimensional accuracy of steel wire rod is secured through a combination of precise manufacturing techniques, mechanical treatments, regular inspections, and quality control procedures. These measures guarantee that the wire rod meets the dimensional requirements for its intended applications.

- Q: What are the main challenges in recycling steel wire rod?

- There are several main challenges in recycling steel wire rod. Firstly, one of the major challenges is the collection and sorting of steel wire rod. Steel wire rod can be found in various forms and sizes, which makes it difficult to separate it from other materials during the recycling process. This requires advanced sorting technologies and efficient collection systems to ensure that only steel wire rod is recycled and other materials are properly sorted out. Secondly, the presence of contaminants in steel wire rod poses a challenge in the recycling process. Steel wire rod often contains coatings, such as zinc or other metals, which need to be removed before recycling. These coatings can hinder the quality of the recycled steel and may require additional processing steps to ensure the purity of the final product. Another challenge is the energy-intensive nature of recycling steel wire rod. The melting process used to recycle steel wire rod requires high temperatures and consumes a significant amount of energy. This can be a challenge in terms of both cost and environmental impact, as it contributes to greenhouse gas emissions and requires substantial energy resources. Furthermore, the transportation and logistics of steel wire rod recycling can be a challenge. Steel wire rod is often bulky and heavy, which increases transportation costs and requires specialized equipment for handling and processing. The logistics of collecting, transporting, and storing steel wire rod for recycling can be complex and require efficient coordination to ensure a smooth recycling process. Lastly, the market demand for recycled steel wire rod can fluctuate, which can pose challenges for recycling facilities. The demand for steel wire rod depends on various factors, such as the economic conditions, construction activities, and infrastructure development. When the market demand is low, recycling facilities may struggle to find buyers for their recycled steel wire rod, which can affect the profitability and viability of the recycling process. In conclusion, the main challenges in recycling steel wire rod include collection and sorting, removal of contaminants, energy consumption, transportation and logistics, and market demand fluctuations. Addressing these challenges requires technological advancements, efficient processes, and a strong market demand for recycled steel wire rod.

- Q: How is steel wire rod used in the production of wire mesh for agricultural applications?

- Steel wire rods are used in the production of wire mesh for agricultural applications by being drawn through a series of dies to reduce their diameter, resulting in wire of the desired thickness. This wire is then woven or welded together to form a mesh, which is used for various agricultural purposes such as securing fences, creating cages for livestock, and constructing trellises for plants. The strength and durability of steel wire rods make them ideal for withstanding the harsh conditions and heavy loads often encountered in agricultural settings.

- Q: How is steel wire rod used in the manufacturing of wire forms for conveyor systems?

- Steel wire rod is an essential component in the manufacturing of wire forms for conveyor systems. It serves as the raw material from which wire forms are created. The wire rod is first processed by undergoing a series of mechanical and thermal treatments, such as hot rolling, cold drawing, and annealing, to enhance its strength, ductility, and flexibility. Once the wire rod has been properly processed, it is then formed into various wire shapes that are specifically designed for conveyor systems. These wire forms can include wire mesh belts, wire spirals, wire ropes, and wire hooks, among others. Each wire form serves a specific purpose in the conveyor system, such as supporting the weight of the conveyed material, guiding the movement of the conveyor belt, or securing and fastening various components of the system. The steel wire rod used in the manufacturing of wire forms for conveyor systems is chosen for its high tensile strength, corrosion resistance, and durability. These properties ensure that the wire forms can withstand the harsh operating conditions of conveyor systems, such as heavy loads, high speeds, and exposure to various environmental factors. Overall, steel wire rod plays a crucial role in the manufacturing of wire forms for conveyor systems by providing the necessary raw material with the required mechanical properties. Its utilization ensures the reliable and efficient operation of conveyor systems in various industries, including mining, manufacturing, transportation, and logistics.

- Q: What are the different types of finishes available for steel wire rod?

- There are several different types of finishes available for steel wire rod, each serving a specific purpose and providing unique properties. 1. Bright Finish: This is the most basic and common finish for steel wire rod. It is achieved by removing any scale or rust from the surface of the rod, resulting in a shiny and smooth appearance. Bright finish is often used for applications where aesthetics are important, such as decorative purposes or in products that are visible to consumers. 2. Galvanized Finish: Galvanizing is a process of applying a protective zinc coating to the surface of the steel wire rod. This finish provides excellent corrosion resistance and is commonly used in outdoor applications or environments with high moisture or humidity. It also offers some degree of abrasion resistance, making it suitable for certain industrial applications. 3. Phosphate Finish: Phosphating is a chemical process that creates a thin layer of phosphate coating on the surface of the steel wire rod. This finish enhances the adhesion of lubricants or coatings, improving the wire's performance in applications where lubrication or corrosion resistance is critical. Phosphate finishes are commonly used in automotive and manufacturing industries. 4. Coated Finish: Steel wire rod can be coated with various materials to provide specific properties. For example, epoxy coatings offer excellent corrosion resistance and are often used in marine or chemical environments. Polymer coatings can provide abrasion resistance, electrical insulation, or improved adhesion properties. Coated finishes are typically tailored to meet specific application requirements. 5. Black Oxide Finish: Also known as blackening, this finish is achieved by converting the surface layer of steel wire rod into a black iron oxide compound. Black oxide finishes provide mild corrosion resistance and improve the wire's appearance. They are commonly used in applications where a black or darkened finish is desired, such as in architectural or decorative products. 6. Zinc-Nickel Finish: This finish is a combination of zinc and nickel plating, providing enhanced corrosion resistance compared to traditional galvanized finishes. Zinc-nickel coatings are commonly used in automotive and aerospace industries, where high corrosion resistance is required. These are just a few examples of the different types of finishes available for steel wire rod. The choice of finish depends on the intended application and the specific properties required, such as corrosion resistance, abrasion resistance, or aesthetics.

- Q: What are the different wire drawing processes used for steel wire rod?

- Steel wire rod can undergo various wire drawing processes to achieve a thinner and more uniform wire with specific properties. The primary wire drawing processes for steel wire rod include: 1. Annealing: By heating the steel wire rod to a specific temperature and slowly cooling it, internal stresses are relieved. This process enhances the wire's ductility and machinability, making it easier to draw into a thinner diameter. 2. Pointing: Before drawing, the ends of the steel wire rod are typically pointed. This is done by grinding or tapering the ends to reduce their diameter, allowing for smooth passage through the drawing die. 3. Drawing: The main step in wire production is the drawing process. Here, the steel wire rod is pulled through a series of dies to decrease its diameter and increase its length. This process is usually carried out in multiple stages, with each stage employing a smaller drawing die to further reduce the wire's diameter. Drawing also enhances the wire's mechanical properties, including strength and hardness. 4. Cleaning and coating: After the wire is drawn, it is often cleaned and coated to shield it from corrosion. This involves removing residual lubricants or contaminants from the drawing process and applying a protective coating, such as zinc or copper, to enhance the wire's resistance to corrosion. 5. Heat treatment: Depending on the desired properties, the wire may undergo additional heat treatment processes after drawing. These can include quenching and tempering, which further improve the wire's strength, toughness, and flexibility. In summary, the various wire drawing processes used for steel wire rod are crucial in transforming the raw material into a final wire product with specific dimensions, mechanical properties, and surface characteristics. Each step in the process plays a vital role in ensuring the quality and performance of the end product.

Send your message to us

Export steel wire rod from China in different grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 12984 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords