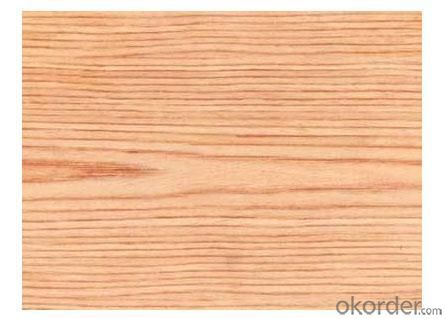

Exotic Wood Veneers - Natural Red Oak Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the natural red oak veneer

| Veneer size | 2200-3000*130+0.5 |

| Grade | A, B,C |

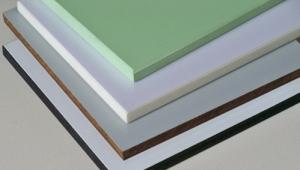

| Applications | furniture making, interior and exterior decoration |

| Species | red oak |

| Packing | standard exporting packing |

The advantages of the natural red oak veneer

A) high quality of the natural red oak veneer, no sound and dead knot, no hole and very clean

B) professtional team for your whole exporting process

C) moisture: to be 8-10% at time of shippment

D) various species and various colors to meet your requirements

E) the natural red oak veneer can make the furniture appear especially high grade

F) applied in the modern design and traditional classic design

other wood species for the natural veneer

White oak, teak, russian oak, sapeli, russian birch, american walnut, maple, cherry.

Application of the natural red oak veneer

The cutting style of the natural red oak veneer is sliced or rotary cut, it is widly used in the furniture

making, interior and exterior decoration. Especially for face or back-fancy plywood, flooring. It is

stable supply for both crown and quarter.

The following pictures for reference

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- In personal terms. Science and technology veneer in the next few years will be to a certain extent, replace the natural veneer. hope this helps. Pure hand hope to give points. You can also ask

- Q: How to seize the key to solve the problem of slow development of paste veneer process?

- However, due to the development of paste veneer technology is relatively lagging behind, part of the veneer products, the appearance and durability of the product failed to be effectively guaranteed

- Q: A lot of Advantages of veneer

- The same mild touch as the logs. More economical than the logs, low prices. Easy to apply to all kinds of body, painting versatility.

- Q: Paste veneer craft specifically refers to what

- Because of the existence of these defects, with the universal glue and white latex can not solve the arc-shaped furniture or furniture, arc parts of the bubble, cracking, overflow rubber and other issues

- Q: Slicing of thin slices of wood

- after cooking treatment; the cooking process should be reduced to more than 40 ℃, it should slow down the heating rate

- Q: What can the veneer be classified?

- by type of classification Can be divided into natural thin wood; dyeing thin wood; combination of thin wood (technology veneer); splicing veneer; into thin velvet (non-woven veneer).

- Q: Brief description of veneer production process

- Of the wooden side should be promptly placed in the paver before the wood temperature of the tank, the insulation in the range of 40 ~ 50 ℃ (with the species and thin wood thickness may be).

- Q: Often, the processing of natural vines is done by slicing the method.

- The program is reasonable not only the high rate of production, and the system is made of chopped thin wood, chord thin wood, the resulting high value of decorative products.

- Q: Veneer has a very affordable, versatile features

- Veneer used in all kinds of high-grade wood decorative leather furniture on the surface, not only the price is reasonable and the function is also particularly good

- Q: What is the size of the veneer?

- 2.45 meters above the general is called large sheet material. The longest domestic veneer is generally about 2.7 meters,

Send your message to us

Exotic Wood Veneers - Natural Red Oak Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords