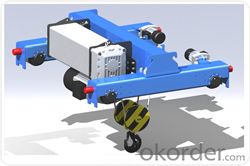

Europe style double rail electric hoist

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Based on bring in and assimilating foreign advanced technology, this type of electric hoist trolley takes modular design theories as guidance, uses modern computer technology as means, introduces optimized and reliable design method, which is new type of hoist made by employing inport configuration, new material and technology and has features in light-weight, generalizing, energy-conservation and environmental protection, maintenance free and high technology content.

This type Europe standard electric hoist applied in industry of machinery production, assembling, petrochemicals, warehouse logistics, electric power construction, papermaking and railways.

Design, production and inspection carry out the last issued relevant national standard,equivalently adopts some foreign criteria including FEM, DIN and IEC . As the core component of driving mechanism, reducer gear pair with hard tooth surface and high accuracy, together with steel reel, forged wheel and variable-frequency speed regulating system , which makes this type of crane become renewal product of traditional .

Features:

1.High Efficiency and Make the Most of space

2.Accurate orientation,highly-efficient operation,improved logistics efficiency.

3.Safe and reliable,monitored operation,easy maintenance.

4.Modularized desigh,low maintenance cost,perfect spare parts and components services

Product Features:Job level is high,can be applied to all kinds of bad place,and the price is good. Note: can be according to your request make non-standard products.

Technical Data:

S.W.L (kg) | FEM | ISO | Hoisting height(m) | Hoisting Speed(m/min) | Traveling Speed(m/min) | Size H (mm) | Size C (mm) |

2000 | 3M | M6 | 6/9/12/18 | 0.8/5.0 | 5~20 | 463 | 350 |

3200 | 2M | M5 | 6/9/12/18 | 0.8/5.0 | 5~20 | 463 | 350 |

5000 | 2M | M5 | 6/9/12/18 | 0.8/5.0 | 5~20 | 463 | 350 |

6300 | 1AM | M4 | 6/9/12/18 | 0.8/5.0 | 5~20 | 463 | 350 |

8000 | 3M | M6 | 6/9/12/18 | 0.8/5.0 | 5~20 | 580 | 563 |

10000 | 1AM | M4 | 6/9/12/18 | 1.0/6.3 | 5~20 | 580 | 563 |

10000 | 2M | M5 | 6/9/12/18 | 0.8/5.0 | 5~20 | 580 | 563 |

10000 | 3M | M6 | 6/9/12/18 | 0.66/4.0 | 5~20 | 580 | 563 |

12500 | 1AM | M4 | 6/9/12/18 | 0.8/5.0 | 5~20 | 580 | 563 |

12500 | 1AM | M4 | 6/9/12/18 | 1.0/6.3 | 5~20 | 679 | 700 |

12500 | 2M | M5 | 6/9/12/18 | 0.6/4.0 | 5~20 | 679 | 700 |

16000 | 2M | M5 | 6/9/12/18 | 0.66/4.0 | 5~20 | 679 | 700 |

20000 | 1AM | M4 | 6/9/12/18 | 0.66/4.0 | 5~20 | 679 | 700 |

20000 | 2M | M5 | 6/9/12/18 | 0.53/3.4 | 5~20 | 679 | 700 |

20000 | 3M | M6 | 6/9/12/18 | 1.0/4.2 | 5~20 | 864 | 1000 |

25000 | 1AM | M4 | 6/9/12/18 | 0.53/3.4 | 5~20 | 864 | 1000 |

25000 | 3M | M6 | 6/9/12/18 | 0.8/3.3 | 5~20 | 864 | 1000 |

25000 | 2M | M5 | 6/9/12/18 | 1.0/4.2 | 5~20 | 864 | 1000 |

32000 | 2M | M5 | 6/9/12/18 | 0.8/3.3 | 5~20 | 864 | 1000 |

32000 | 2M | M5 | 6/9/12/18 | 0~4.9 | 5~20 | 1023 | 950 |

40000 | 1AM | M4 | 6/9/12/18 | 0~4.9 | 5~20 | 1023 | 950 |

50000 | 2M | M5 | 6/9/12/18 | 0~3.2 | 5~20 | 1023 | 950 |

50000 | 1AM | M4 | 6/9/12/18 | 0~4.1 | 5~20 | 1023 | 950 |

63000 | 1AM | M4 | 6/9/12/18 | 0~3.2 | 5~20 | 1023 | 950 |

63000 | 2M | M5 | 6/9/12/18 | 0~2.4 | 5~20 | 1023 | 1110 |

80000 | 1AM | M4 | 6/9/12/18 | 0~2.4 | 5~20 | 1023 | 1110 |

- Q: This question asks about the measures to ensure that safety belts on a building hoist are correctly installed and utilized.

- <p>To ensure that safety belts on a building hoist are properly installed and used, follow these steps: 1. Regularly inspect the belts for any signs of wear, damage, or corrosion. 2. Ensure that the belts are securely fastened and properly adjusted according to the manufacturer's guidelines. 3. Conduct a thorough pre-use inspection before each operation to confirm that the belts are in good condition and functioning correctly. 4. Train all personnel on the proper use of safety belts and the importance of wearing them at all times while operating the hoist. 5. Implement a maintenance schedule to regularly check, clean, and lubricate the belts to prolong their lifespan and ensure optimal performance. 6. Replace any damaged belts immediately to prevent accidents and ensure the safety of workers.</p>

- Q: The user is asking if it's possible to substitute a hydraulic lifting device for a building hoist in construction.

- <p>Yes, a hydraulic lifting device can be used as an alternative to a building hoist in certain scenarios. Hydraulic devices offer precise control and smooth operation, which can be advantageous for lifting heavy construction materials. However, it's important to consider the specific requirements of your project, such as the weight and size of the materials to be lifted, the height of the lift, and the frequency of use. Hydraulic systems are generally more expensive and require more maintenance than building hoists, but they can provide greater lifting capacity and versatility. Always ensure that any lifting device used complies with safety standards and regulations.</p>

- Q: The construction elevator can only go up can't come down what happened

- Does the motor have electricity when it falls? Look at the switch and the line first, then check the controller.

- Q: This question asks for the steps or methods to fix a building hoist that is not working properly.

- <p>To repair a malfunctioning building hoist, first, ensure the hoist is powered off and disconnected from any power source to ensure safety. Inspect the hoist for visible damage or loose parts. Check the motor, cables, and control panel for any signs of wear or damage. If the issue is mechanical, such as a stuck cable or a jammed pulley, disassemble the affected parts and clean or replace them as necessary. For electrical issues, inspect the wiring and connections for any shorts or breaks. Consult the hoist's manual for troubleshooting guides specific to the model. If the problem persists or if you're unsure about any steps, it's best to contact a professional technician for repair to avoid further damage or safety hazards.</p>

- Q: What are the primary materials that are commonly utilized in the construction of hoists?

- <p>Hoists are typically constructed using a combination of metals and synthetic materials for strength and durability. Steel, particularly alloy steel, is a common choice due to its high tensile strength and resistance to wear. Aluminum is also used for its lightweight properties, especially in mobile hoists. Synthetic materials such as nylon or polyester are used for hoist ropes and cables due to their resistance to abrasion and corrosion. Additionally, hoists may incorporate components made from brass, bronze, or other metals for specific parts that require low friction or high resistance to corrosion.</p>

- Q: This question asks about the measures taken to ensure that lifting equipment remains safe and functional in various weather conditions.

- <p>To ensure that lifting equipment is safe and reliable in all weather conditions, regular maintenance and inspection are crucial. Equipment should be designed with weather-resistant materials and should be tested periodically to withstand extreme temperatures, humidity, and precipitation. Protective covers or enclosures can be used to shield equipment from the elements. Additionally, training operators on the safe use of equipment in different weather conditions is essential. Emergency procedures should be in place for extreme weather events, and equipment should be regularly checked for wear and tear that could be exacerbated by weather conditions.</p>

- Q: The maximum allowable deviation of the vertical is the vertical degree when the construction elevator is installed

- The development of the elevator is in a peak state, because most of the manufacturers or individuals to improve the utilization efficiency of space, more options for multistory buildings, which also need a device to convenient up and down by the goods. Due to the common elevator cost is high, bearing capacity is low, not suitable for carrying dozens of tons or hundreds of tons of cargo, so developed a high bearing capacity of hydraulic lift to assist in the production and transportation of goods. The elevators are both safe and super loadable, and convenient for maintenance, making the special industry grow faster.

- Q: Is it possible to utilize a building hoist for the transportation of heavy objects?

- <p>Yes, building hoists are specifically designed to move heavy objects vertically within a construction site. They are used to lift and lower materials such as concrete, bricks, and other construction supplies. Building hoists are equipped with strong cables and a robust mechanism to handle significant weight, making them ideal for heavy-duty lifting tasks in construction projects. However, it's crucial to ensure that the hoist is operated within its weight capacity and safety guidelines are strictly followed to prevent accidents.</p>

- Q: This question asks for guidelines on how to take care of lifting equipment after it has been used.

- <p>To maintain your lifting equipment after use, follow these steps: 1. Clean the equipment thoroughly to remove dirt, grease, and any debris. 2. Inspect all components for wear, damage, or signs of excessive use. 3. Lubricate moving parts as per the manufacturer's recommendations. 4. Check and tighten all bolts, nuts, and fasteners to ensure they are secure. 5. Store the equipment in a dry, clean, and well-ventilated area to prevent rust and corrosion. 6. Regularly review the manufacturer's maintenance schedule and perform any required servicing. 7. Keep a log of all maintenance and inspections to ensure you're staying on top of equipment care. Proper maintenance not only prolongs the life of your equipment but also ensures safety during use.</p>

- Q: Is it possible to replace an electric motor with a hydraulic cylinder in an electric-hydraulic lifting system?

- <p>No, a hydraulic cylinder cannot be used in place of a motor in an electric-hydraulic lifting system. A hydraulic cylinder is a component that converts hydraulic pressure into linear motion, while an electric motor converts electrical energy into mechanical energy. In an electric-hydraulic system, the motor drives a hydraulic pump, which generates the pressure needed to actuate the cylinder. The motor is essential for providing the power source, and the cylinder is the actuator that uses this power to perform work. Replacing the motor with a cylinder would result in a system without a power source, rendering it inoperative.</p>

Send your message to us

Europe style double rail electric hoist

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords