ETP in MR/ SPCC Steel for General Can Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Products: Tinplate

Tinplate and TFS are widely used for making all types of containers such as artistic cans, tea cans, painting cans, chemical package cans and metal printing etc. Its applications are not limited to containers; recently, they have also been used for making electrical machinery parts and many other products.

2. Specification:

Our goods enjoyed high quality both at home and abroad. We can supply tin free steel as follows:

Technical standard | JISG3303 and GB/T 2520-2008 |

Steel Type | MR / SPCC |

Thickness | From 0.15mm to 0.50mm (Tolerance +/- 0.01mm) |

Width | Normally 600-1050mm (Tolerance +3/-0 mm) |

Coating | 2.8/2.8g/m2 , 2.8/5.6g/m2 ,1.1/1.1 g/m2 |

Temper & Annealing | T1-T5, DR7-8, TS230-TH435, T49-T65(+/- 4) |

Surface Treatment | Bright & Fine Stone & Stone & Silver & Matt |

Payment terms | Letter of Credit (L/C), Telegraphic transfer (T/T) |

Price terms | CFR & CIF price term |

Delivery time | Within 60 days after received L/C or T/T down payment |

Packing | High quality shipping packing which contains thin plastic film, rust-proof paper, metal cover, metal angles and strap sand pallet. |

Minimum order Quantity(MOQ) | 25 metric tons (1X 20'' container) |

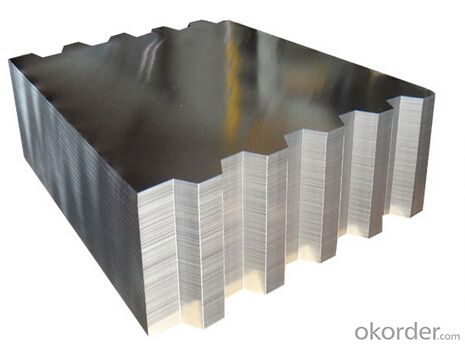

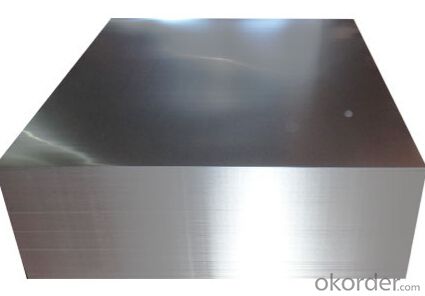

3. Pictures:

4. Features of the factory price/ tin free steel/tinplate/tfs/tmbp/etp/spte:

Beautiful Appearance

Excellent Paintability & Printability

Excellent Formability & Strength

Excellent Corrosion Resistance

Excellent Solderability & Weldability

5. FAQ:

We are one of the main producers in China for tinplate, tin free steel and also TMBP. At present, our productivity is more than 450000 MT/year.

For more information about our products or company, pls contact us freely.

Welcome your enquiries and orders.

- Q: How does tinplate contribute to the presentation of jewelry?

- Tinplate is often used in the packaging of jewelry, such as boxes or containers, which enhances the presentation and adds an element of luxury. Its glossy and reflective surface provides a visually appealing backdrop for showcasing the beauty and intricacy of the jewelry inside. Additionally, tinplate offers excellent protection against corrosion and moisture, ensuring the longevity and preservation of the jewelry.

- Q: How is tinplate tested for corrosion resistance?

- Tinplate is tested for corrosion resistance through various methods, including salt spray testing, electrochemical impedance spectroscopy, and weight loss analysis. These tests evaluate the ability of tinplate to withstand exposure to corrosive environments and provide insights into its protective properties.

- Q: Is tinplate resistant to corrosion?

- Yes, tinplate is resistant to corrosion.

- Q: What are the common sizes and shapes of tinplate products?

- Common sizes and shapes of tinplate products vary depending on their purpose and industry. However, some commonly seen sizes include cans ranging from small containers for food and beverages (such as soda cans) to larger ones for bulk products (such as paint cans). Tinplate products also come in various shapes, including rectangular, cylindrical, and irregular forms, to cater to different packaging needs and maximize storage efficiency.

- Q: What are the printing options for tinplate?

- The printing options for tinplate include lithography, screen printing, and digital printing.

- Q: Can tinplate be used for packaging wine or spirits?

- Yes, tinplate can be used for packaging wine or spirits. Tinplate is a durable and corrosion-resistant material that provides excellent protection against light, oxygen, and moisture. It also offers a classic and premium appearance, making it a popular choice for wine and spirits packaging.

- Q: Tinned iron and iron matte tin in difference

- While in tinplate iron or iron matte silver, the surface is sandy, so people often referred to as silver iron, its price is a tin material price is more expensive, generally can usually used without printing packing, for printed cans is usually to is sandy, it is generally. Iron printing, matte iron tensile and hardness of tin iron generally not good, some specifications of tinplate is not suitable for stretching relatively large.

- Q: How is tinplate manufactured?

- Tinplate is manufactured through a process called electroplating, where a thin layer of tin is deposited onto a steel sheet. The steel sheet is first cleaned and then passed through an electrolyte bath containing tin salts. Electric current is then applied to the bath, causing the tin ions to be attracted to the steel sheet and form a uniform coating. This tin coating provides corrosion resistance and enhances the appearance of the steel sheet, making it suitable for various applications such as food cans and packaging materials.

- Q: Can tinplate be used for non-food products?

- Yes, tinplate can be used for non-food products. Tinplate is a versatile material that can be used in various industries such as automotive, construction, electronics, and packaging. Its corrosion resistance and durability make it suitable for non-food applications like metal cans, aerosol containers, electrical enclosures, and decorative items.

- Q: How does tinplate impact the ease of opening and closing packaging?

- Tinplate, due to its durability and flexibility, positively impacts the ease of opening and closing packaging. It provides a sturdy and secure enclosure, ensuring that the package remains intact during transportation and storage. Additionally, tinplate's smooth surface allows for effortless opening and closing, making it convenient for consumers to access the contents of the packaging.

Send your message to us

ETP in MR/ SPCC Steel for General Can Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords