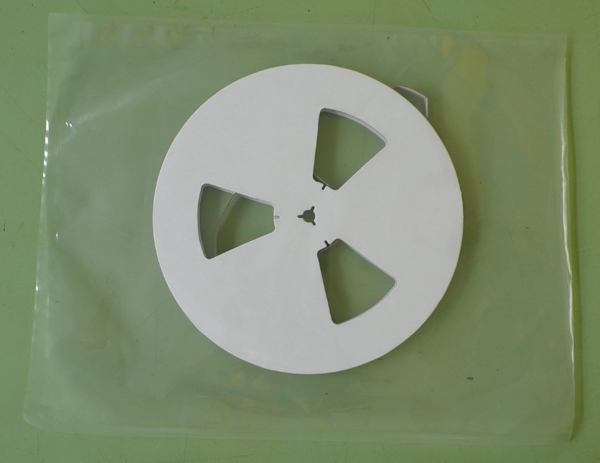

ESD Transparent Vacuum Bag

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Feature:

It is applied for vacuum packing of precise components, PCB and so on.;

The special production technique makes material good anti-tearing property;

Transparent color is convenient to identify inside products.

Service and Quality Control:

All kinds of printing services are available;

Various thicknesses are available and different bag types can be customized;

The third-party testing reports can be offered;

- Q: Express carton packaging, plastic packaging should be how to deal with?

- Most of these packages are thrown away, but this creates environmental pollution and adds to the difficulty of garbage disposal. Environmentally conscious people remove plastic bags and use a knife to remove them from one end of the package, leaving a complete open pocket after opening. Put it in the garbage basket and you can use it as a garbage bag. Full of rubbish, can hold the bag at both ends to the middle or pull sealing, or you can pull a direct sealing tape. This estimate, in general, often online shopping crowd in a week can use two express packaging, "modified" garbage bags, a year down, you can save more than one hundred new garbage bags.

- Q: The package specifications are 9 multiplied by 14 plus 3. How big is it?

- The height of the bag is 14CM, the width is 9CM, and the width of the side is 3CM. The bag type belongs to the organ bag!

- Q: What about the use of plastic bags?

- There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

- Q: What's the raw material of the cement packing bag?

- The raw material is polypropylene resin cement packaging bags, mainly for foreign production of polyethylene (PE), mainly for the domestic production of polypropylene (PP), then add some additives, after the heating wire drawing, then weaving, printing and so on, the higher the quality of the cement bag inner lining!

- Q: What are the soft and hard sides of plastic bags? Material or process technology?

- The quality of plastic packaging is determined by both the material and the process. The material is no better than the good one. But the hardness of plastic is not a decisive factor in determining the quality of plastic, mainly to see what the use of what needs to keep products

- Q: What material is the packing bag for pure milk, please?

- W1l203 (station contact TA) should be food grade polyethylene, safe, easy to tear learn1986 (station contact TA), aluminum foil and polyethylene plastic film and paper interaction combined into polyethylene aluminum plastic composite packaging materials.

- Q: What are the requirements of the gas in the package?

- The higher requirements are modified packaging: oxygen, nitrogen and carbon dioxide are used to fill the package in proportion to the product - respiration - use, to extend the shelf life of the product, and outside

- Q: Antistatic packaging bag with chip

- Then anti-static shielding bag, black is conductive electrostatic material, regular 1000 ohm resistance, or is translucent gray, middle layer aluminized bag, play an important role in shielding

- Q: Printing solvent for food packing bag

- Use a moisture indicator to determine the content in the solvent. The water indicator is put into the solvent, and the water content varies with different colors. Depending on the color change, the amount of water in the solvent can be roughly determined.

- Q: How many kinds of packing bags are there in the packaged foods?

- PE's softness and mechanical properties are worse than those of PP. It represents shopping bags, plastic wrap, garbage bags and so on.PP is stiffer, anisotropic (with a notch that is easily ripped), has good mechanical properties, and is superior to PE in high-temperature performance, representing bread bags.I wonder if this answer has met your requirement.

Send your message to us

ESD Transparent Vacuum Bag

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords