Engineered Flooring Outdoor Wood Plastic Composite WPC Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

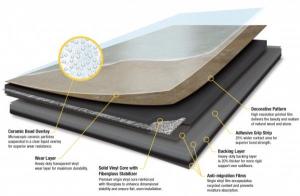

一. Structure of Engineered Flooring Outdoor Wood Plastic Composite WPC Decking

Item | WPC Project Decking-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Engineered Flooring Outdoor Wood Plastic Composite WPC Decking

Engineered Flooring Outdoor Wood Plastic Composite WPC Decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

三.Wood Plastic Decking Images

四.Engineered Flooring Outdoor Wood Plastic Composite WPC Decking Specification

Name | Engineered Flooring Outdoor Wood Plastic Composite WPC Decking |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2900mm, 5400mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Engineered Flooring Outdoor Wood Plastic Composite WPC Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: Plastic floor can be used indoors

- Compared with wood plastic floor: 1, fireproof performance, flame spread, anti burning cigarette burns; 2, surface hardness, scratch resistant properties than wood; 3, not easy to deformation, good dimensional stability; 4, pattern design, decorative effect, pattern selection is better than the floor; 5, with better performance, can heat welding processing, so that the seam is achieved completely waterproof, dustproof, waterproof, anti bacteria, mildew, moth effect; 6, the noise is small, can be reduced by 6-14 dB, more conducive to noise control when walking; 7, wide application range, not only suitable for Home Furnishing is also suitable for the local flow in many public places and others

- Q: How long can be used for plastic floor restaurant

- Commercial flooring / plastic flooring1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material3, commercial floor uses: kindergarten, office, stairs, family, factory, school, hotel, hotel4, life: 6 years to more than 15 years5, thickness: 2 mm6, color: more than 207, size: 20 meters long, width of 1.8 meters, 2 meters8, suppliers: Shanghai, Shanghai and the United States floor9, price: different thickness, different grades, different PVC content, different prices.10: Shanghai, the United States and the United States commercial floor price of 2 mm to 50 yuan per square meter installation price11, place: gray, wood12, family selection: red, blue, black, wood13, kindergarten; pink, green, yellow

- Q: To warm the original heat, the plastic floor above the surface of the floor to warm the heat emitted by the heat of the gas smell harmful to the human body?

- Resolutely not allowed to use!Plastic floor leather is a soft floor, PVC resin as the main raw material

- Q: How to tear off the plastic film on the floor tiles

- To be transferred to the factory, in order to prevent damage to the floor during the renovation, in the brick surface have done a deal with the pollution, the general polishing brick made of anti fouling wax

- Q: What plastic floor

- Super wear-resistant: ground material wear resistance, depending on the surface of the wear-resistant layer of material and thickness, not only to see the total thickness of its tiles. Pvc floor surface covered with 0.1-0.13mm thickness of high polymer material, high wear resistance, the longest life expectancy for similar products. A thin layer of transparent film on the composite wood floor or a layer of glaze on the ceramic tile, there is nothing less than.

- Q: How to spread plastic floor tiles

- Ground mark: the first floor of the ground height is set to the relative elevation of the zero, with nylon thread or cotton rope on the ground pull out the ground mark line, as well as the vertical cross positioning line. Position the tile according to the position of the positioning line.

- Q: The plastic floor gives off a plastic smell. Is it harmful?

- Therefore, we must use a very strong glue. Linseed oil as PVC stable. Linseed oil need maintenance in natural light. The result is: the samples and the real difference, there will be yellow, linseed oil for the maintenance of products (pH > 7) poor resistance. Linseed oil RE polishing, waxing, must use the special products

- Q: Plastic floor how to taste?

- We can Naganbu wet, dry for 2 minutes, mainly to prevent Bree water penetrated into the surface, and then take the wet cloth to clean the floor.

- Q: Plastic foam on the floor there is no effect of moisture

- The plastic film under the wooden floor is called the ground mat, which can be used to play the role of moisture. Prevent moisture and moisture, so as to avoid the floor because of water seepage to the wood floor deformation. If there is no ground floor and the floor will be rubbing friction sound. There is also can play a role in the formation of the ground. Is an indispensable procedure.

- Q: Home decoration, floor requirements should be very flat

- Hello, like now is winter, low temperature period should pay special attention to prevent the occurrence of bad construction measures

Send your message to us

Engineered Flooring Outdoor Wood Plastic Composite WPC Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords