Electromagnetic Contactor Mitsubishi S-T35 Elevtric Apparatus For Control

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

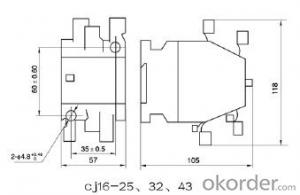

Specification

Electromagnetic contactor (contactor) refers to an electrical appliance that

uses the current flowing through the coil to generate a magnetic field in

industrial electricity to close the contact so as to control the load. The

contactor is composed of electromagnetic system (armature, stator core,

electromagnetic coil), contact system (normally open contact and normally

closed contact) and arc extinguishing device.

Structural composition

Electromagnetic contactor is mainly composed of transmission device

(electromagnetic mechanism), contact device (actuator) and arc extinguishing

device.

1. Electromagnetic mechanism

The electromagnetic mechanism includes three parts: moving core (armature),

static core and electromagnetic coil. The electromagnetic coil is connected

with current to generate electromagnetic suction and drive the contact to act.

Electromagnetic mechanism is one of the important parts of electromagnetic

contactor. The electromagnetic mechanism is composed of coil, iron core (static

iron core), armature (moving iron core), pole shoe, iron yoke and air gap. The

coil and iron core in the electromagnetic mechanism do not move in the working

state; The armature is movable.

The electromagnetic mechanism converts the electromagnetic energy generated by

the electromagnetic coil into mechanical energy through the action state and

action process of the armature and the corresponding mechanical mechanism to

drive the contact to close or open, so as to realize the control purpose of the

controlled circuit.

2. Contact device

There are many structural forms of contact, which can be divided into: main

contact and auxiliary contact according to the control circuit;

The contact is divided into normally open contact and normally closed contact

according to its original state;

The contact is divided into bridge contact and finger contact according to its

structural form.

3. Arc extinguishing device

Arc extinguishing cover is an insulated and high temperature resistant arc

extinguishing device made of clay and asbestos cement. It is a simple arc

extinguishing device.

When using the arc extinguishing cover device to extinguish the arc, the

longitudinal seam arc extinguishing method is generally used in the arc

extinguishing cover.

Common arc extinguishing devices: arc extinguishing cover (arc resistant clay,

asbestos cement and arc resistant plastic), arc extinguishing grid (arc

resistant grid sheet copper plated thin steel sheet), magnetic blowing arc

extinguishing device (an arc extinguishing coil is connected in series in the

contact circuit).

4. Other components, including reaction spring, buffer spring, transmission

mechanism and shell, etc.

- Q: What is the traditional AC contactor contact that does not vibrate?

- When the voltage fluctuates in the critical state of closing and opening, the contactor is in the same way, Vibration, resulting in contact welding or burned, leaving the motor burned.

- Q: The contactor is mainly composed

- The other half is the activities of the core, structure and fixed iron core, to drive the main contacts and auxiliary contacts closed off.

- Q: Seeking Star Triangle to start the contactor on and off the order and process

- when the press button SB1, the time relay coil KT and then contact the coil at the same time Power, KMY's moving contact closed

- Q: What is the formulation of the contactor?

- contactor number of auxiliary contacts, and contactor installation options

- Q: Technical development of AC contactor

- After the 1980s, countries to study the exchange of contactor electromagnet silent and energy-saving

- Q: What about the number of AC contactors?

- When the coil is powered off, the suction disappears, and the moving core interlocking part is separated by the reaction force of the spring

- Q: How do I distinguish between contactors and circuit breakers?

- According to the different control voltage can be divided into DC contactor and AC contactor, its main accessories for the auxiliary contact.

- Q: What is the contactor's formula?

- The circuit breaker used to control the motor, whose trip trip trip current should be greater than or equal to (1.5-1.7) times the motor starting current.

- Q: What is the main component of the contactor?

- AC contactor contacts, made of silver tungsten alloy, with good conductivity and high temperature ablation

- Q: Contactor mainly by the drive system, contact system, arc and other components.

- contact system: contact is the implementation of contactor, including the main contact and auxiliary contacts

Send your message to us

Electromagnetic Contactor Mitsubishi S-T35 Elevtric Apparatus For Control

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 2000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches