Electrolytic Tinplate ETP Sheets in good price for Food Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter.

It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

TINPLATE SHEET SPECIFICATION

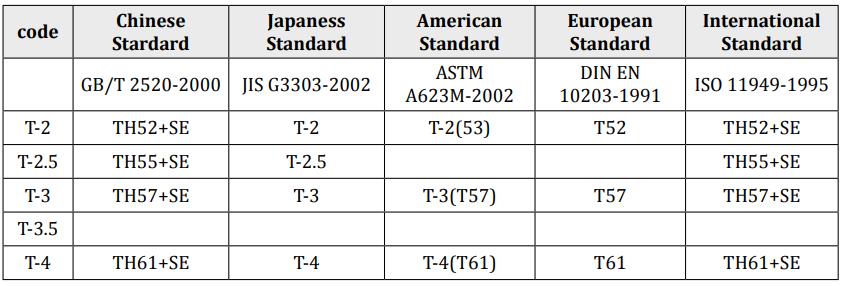

Reference standard: GB/T 2520-2000, JIS G3303-2002 and DIN EN 10203-1991

Raw material: MR and SPCC

Thickness: 0.13 to 0.5mm

Width: 600-1050mm

Length: maximum 1200mm

Temper: T1~T5, DR8~DR10

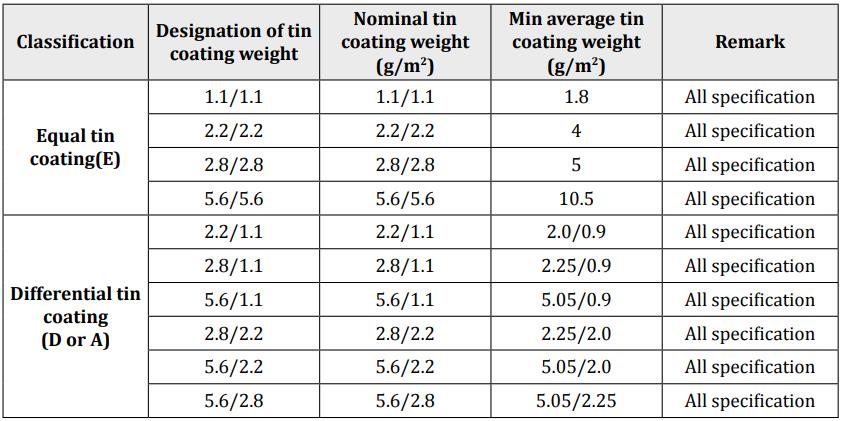

Tin coating: 1.1g~11.2g We can produce according to customer’s requests.

Applications: paint, chemical and other usage can make battery, electric cable and other industries

Package: anti-rust paper, corner protected. Sheets or coils according customer's requests

Stardard

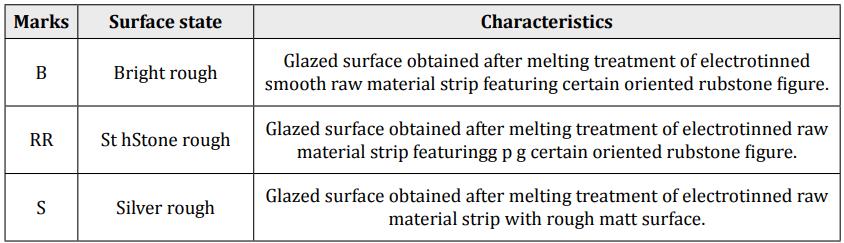

Surface

Coating

APPLICATION

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

◆ Chemicals and painting cans

◆ Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans

◆ Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

◆ Sea food cans

◆ Crown corks, easy open ends (EOE)

◆ Electrical machinery parts

◆ Bakeware and household kitchen parts

- Q: What are the key properties of tinplate?

- The key properties of tinplate include excellent corrosion resistance, high strength, good formability, and the ability to be easily soldered and welded.

- Q: How does tinplate perform in terms of chemical resistance?

- Tinplate generally offers good chemical resistance due to the protective layer of tin that is applied to its surface. This tin coating acts as a barrier against many corrosive substances, preventing them from coming into direct contact with the underlying steel. However, prolonged exposure to highly acidic or alkaline environments can potentially deteriorate the tin coating and compromise the chemical resistance of tinplate.

- Q: What are the environmental impacts of producing tinplate?

- The environmental impacts of producing tinplate include the extraction of raw materials, such as tin and steel, which can lead to habitat destruction and soil erosion. The manufacturing process involves high energy consumption and emissions of greenhouse gases, contributing to climate change. Waste generation, such as water pollution and hazardous byproducts, can also pose risks to ecosystems and human health. Additionally, the transportation and disposal of tinplate products may further contribute to carbon emissions and waste management challenges.

- Q: How does tinplate contribute to the durability of gardening tools?

- Tinplate contributes to the durability of gardening tools by providing a protective coating that prevents rust and corrosion. This helps to extend the lifespan of the tools, making them more resistant to wear and tear caused by exposure to moisture and harsh outdoor conditions.

- Q: Tin cans and tin cans, which is good?

- I think this question is not asked to tin tin, chrome tin and galvanized tin which is the best? Of course, the best is galvanized iron. The second is the tin tin, followed by chrome tin, iron box is made finally.

- Q: What is the purpose of coating tinplate?

- The purpose of coating tinplate is to protect it from corrosion and to enhance its durability and aesthetic appeal.

- Q: How is tinplate coated for aerosol cans?

- Tinplate is coated for aerosol cans through a process called electroplating. The tinplate is immersed in an electrolyte solution and an electric current is passed through it, causing tin ions from the solution to be deposited onto the surface of the tinplate. This electroplating process ensures a thin and uniform layer of tin coating, providing corrosion resistance and a shiny appearance to the aerosol cans.

- Q: How is tinplate coated for gift packaging?

- Tinplate is typically coated for gift packaging using a process called electroplating, where a thin layer of tin is applied to the surface of the tinplate. This coating not only enhances the appearance of the packaging but also provides protection against corrosion and oxidation.

- Q: Can tinplate be used for packaging beauty and skincare products?

- Yes, tinplate can be used for packaging beauty and skincare products. Tinplate is a durable and versatile material that offers excellent protection against moisture, light, and external contaminants. It also provides a premium and aesthetic appeal, making it suitable for high-end beauty and skincare products. Additionally, tinplate is recyclable, making it an eco-friendly packaging option.

- Q: Can tinplate be used for packaging soups and broths?

- Yes, tinplate can be used for packaging soups and broths. Tinplate is a commonly used material in food packaging due to its durability, ability to maintain product freshness, and resistance to corrosion. It provides a reliable barrier against moisture and oxygen, making it suitable for preserving the quality and taste of soups and broths. Additionally, tinplate cans are easy to open and can be safely heated, making them convenient for consumers.

Send your message to us

Electrolytic Tinplate ETP Sheets in good price for Food Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords