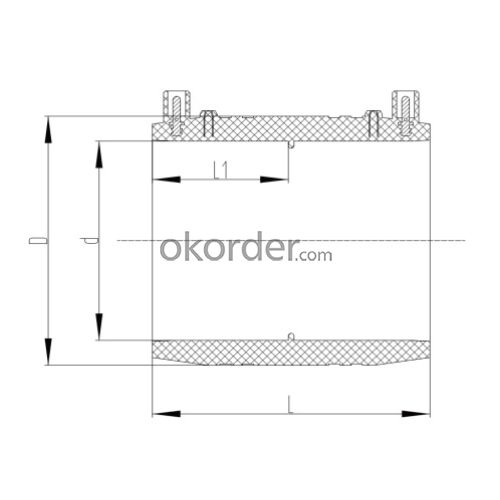

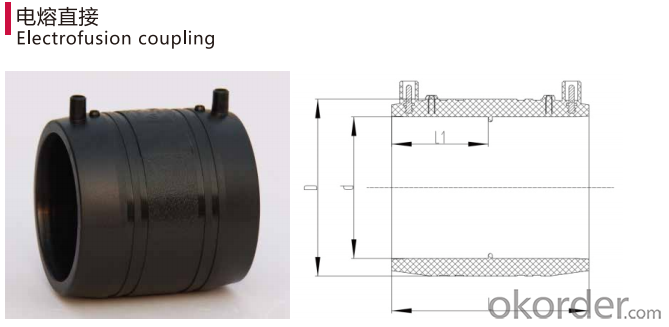

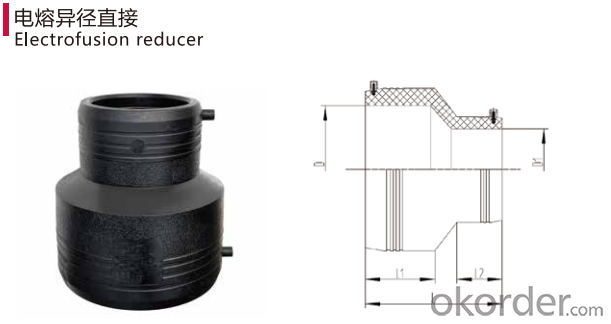

Electrofusion Coupling Reducer PE Pipe Fittings EN12201-3

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

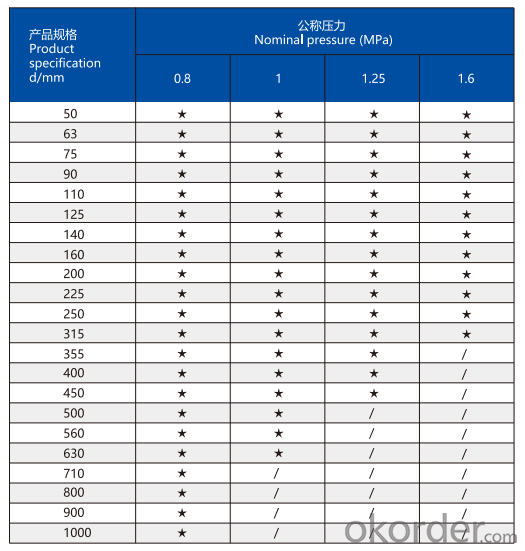

Pressure grade:0.8MPa-1.6MPa

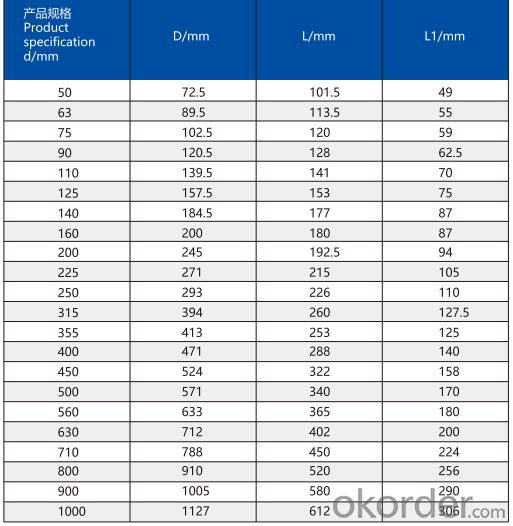

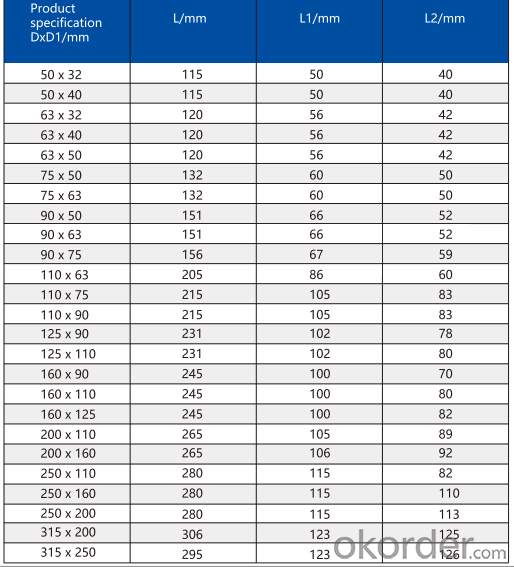

Size: DN50MM-DN1000MM

Specification:

Pressure grade:≤1.6MPa

Size: DN50MM-DN315MM

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q: Are plastic pipe fittings suitable for offshore oil and gas platforms?

- Yes, plastic pipe fittings are suitable for offshore oil and gas platforms. They have several advantages such as corrosion resistance, lightweight construction, and ease of installation and maintenance. Additionally, plastic fittings can withstand harsh environmental conditions and offer cost-effectiveness in comparison to traditional metal fittings. However, it is crucial to consider the specific requirements and conditions of the offshore platform before making a final decision on the suitability of plastic pipe fittings.

- Q: Can plastic pipe fittings be used for fuel transfer systems?

- Plastic pipe fittings are generally not recommended for fuel transfer systems due to the potential risks associated with fuel leakage, corrosion, and chemical compatibility. Metal fittings such as steel or brass are preferred for their durability and resistance to fuel-related hazards.

- Q: Are plastic pipe fittings resistant to UV rays?

- No, plastic pipe fittings are not typically resistant to UV rays, as extended exposure to sunlight can cause them to degrade and become brittle over time.

- Q: How do you choose the right size of plastic pipe fittings?

- To choose the right size of plastic pipe fittings, you need to consider the diameter of the pipe you are using. Measure the outside diameter of the pipe and select fittings that match this size. It is crucial to ensure a proper fit between the pipe and fittings to prevent leaks or disconnections. Additionally, referring to industry standards and consulting with professionals can also help in determining the correct size for your specific application.

- Q: Are plastic pipe fittings resistant to ozone exposure?

- Yes, plastic pipe fittings are generally resistant to ozone exposure.

- Q: The difference between PP-R aluminum pipe and PP-R pure plastic pipe

- From the connection way, aluminum plastic pipe is a physical connection, simple and convenient, unless the operation is improper, its safety and reliability is very high. PE pipes and PP-R pipes with hot melt or welding connection, complex process, easy to produce stacking defects, lead to stress concentration, influencing the long-term performance of pipeline; in addition, the local high temperature fuse facilitates pipeline material degradation, accelerated aging pipeline

- Q: How do plastic pipe fittings handle expansion and contraction in long pipelines?

- Plastic pipe fittings typically handle expansion and contraction in long pipelines through their inherent flexibility and ability to accommodate thermal changes. These fittings are designed to withstand the expansion and contraction caused by temperature fluctuations without compromising the integrity of the pipeline. Additionally, they may incorporate features like expansion joints or flexible couplings that allow for movement and prevent stress on the system.

- Q: Are plastic pipe fittings available in different colors?

- Yes, plastic pipe fittings are available in different colors.

- Q: How are plastic pipe fittings manufactured?

- Plastic pipe fittings are typically manufactured through injection molding. This process involves melting plastic resin pellets and injecting the molten material into a mold cavity. Once the plastic cools and solidifies, the mold is opened, and the finished pipe fitting is ejected. Injection molding allows for the mass production of plastic pipe fittings with consistent dimensions and high precision.

- Q: Can plastic pipe fittings be used for irrigation pumps and filters?

- Yes, plastic pipe fittings can be used for irrigation pumps and filters. Plastic fittings are commonly used in irrigation systems due to their durability, resistance to corrosion, and ease of installation. They provide a reliable and cost-effective solution for connecting pipes, pumps, and filters in irrigation setups.

Send your message to us

Electrofusion Coupling Reducer PE Pipe Fittings EN12201-3

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords