Electrofused Magnesite Refractory Basic Fused Magnesite

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

Place of Origin: Liaoning, China

Application: Refractory

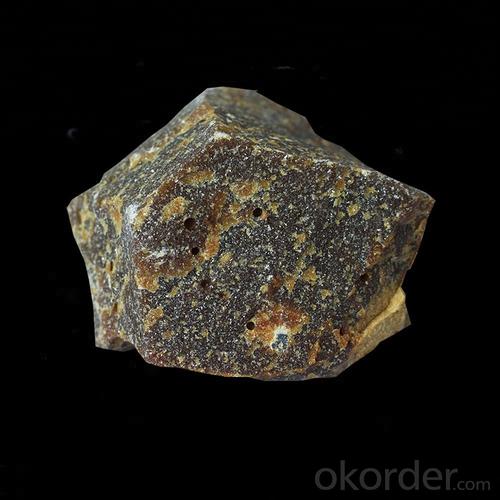

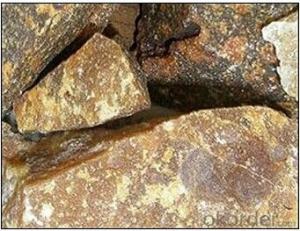

Shape: Block

Material: Magnesite

Chemical Composition: Mgo;CaO;SiO2

Mgo:96%-97%

Product name: FM

Payments terms: 1. 100% L/C at sight 2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Usage: Metallurgy, Foundry, Abrasive, Refractory, Deoxidizer

Advantage: Timely Shipment, High quality, Good performance

Packing: 1mt/bag or as customers' requirements

Size: 0-30mm etc

Sample supply: free sample

Color: Brown, white

MOQ: 25Mt

Supply Ability

Supply Ability:1000 Metric Ton/Metric Tons per Month

Grade | MgO | SiO2 | CaO | Fe2O3 | Al2O3 | Loi | B.D g/cm3 |

Dicalcium-fused magnesium | 97.00 | 0.70 | 1.40 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 0.85 | 1.60 | 0.70 | 0.20 | 0.15 | 3.20-3.30 | |

96.00 | 0.95 | 1.90 | 0.80 | 0.23 | 0.12 | 3.20-3.30 | |

Common fused magnesite | 97.20 | 0.80 | 1.10 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 1.20 | 1.30 | 0.70 | 0.20 | 0.10 | 3.20-3.30 | |

96.00 | 1.40 | 1.50 | 0.80 | 0.20 | 0.10 | 3.20-3.30 | |

Size | 0-1mm, 0-30mm, 1-15mm, 1-30mm, 200mesh or according to customer's requirements. | ||||||

Plant photos:

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

Port Main port of China

Loading:

What is fused magnesite?

Fused magnesite is produced by high quality magnesite through electro- fusing, After melting, the SiO2 of material moves to the surface for the difference in the specific, so it has well grown crystals, well crystal perfection and structure homogeneity, excellent chemical stability, good corrosion resistance to slag and high strength at high temperature.

Where to apply fused magnesite?

It is widely used for gunning materials, fused magnesite ramming material, magnesite brick, magnesite chrome brick, vacuum and vacuum induction furnace, electric arc furnace refractory lining, magnesia crucible, furnace and a variety of refractory, such as large scale glass furnace by floating method, electrical furnace, convert furnace, house hold electrical appliances as electrical insulating materials,

- Q: What are the electrical fire protection materials?

- Flame retardant organic resin: They can be classied into PVC, vinyl chloride, chlorinated rubber, epoxy resin emulsion, epoxy resin, phenolic resin, etc.. Fire retardant additive: Phosphorus and halogens, nitrogen organic compounds (chlorinated paraffin, tributyl phosphate (TBP) and polybrominated diphenyl ethers) and boron (boric acid, zinc borate, boric acid aluminum), antimony, aluminum, zirconium inorganic compounds.

- Q: Who knows what is the external wall thermal insulation materials for level A fireproofing?

- In general, external wall thermal insulation materials can be divided into level A and level B by combustion grading. Level A is non-combustible material, and level B is combustible materials. A few years ago, the fire of the CCTV Building and Shenyang Hotel put the blame on the level B material. At present, the level A material is widely used, and the prices of same level A materials may be even cheaper than the level B material. Level A material is generally divided into thermal?mortar, phenolic foam board, rock wool board and foam cement board. I hope this information can be helpful to you. Hope you adopt.

- Q: What characteristics do A grade external wall fireproofing material have?

- For characteristics of A grade external wall fireproofing material, its main raw material uses cold resistant and thermal insulated, environmental protection and energy saving material with good insulation, keeping the indoor temperature steady and making the environment more comfortable. It is several times better than other masonry in overall strength and resist capability, and it can also hang heavy objects such as air conditioners by directly nailing or installing expansion bolts. Single point hanging machine can withstand heavy objects with the weight of more than 45kg. It can also be directly fixed to the tiles, wallpaper, wooden plaques, paint, etc.

- Q: What material is used to make furnace pipe of refractory bricks?

- Furnace pipe of refractory brick is an indispensable part of casting cupola. Furnace pipe is divided into upper and lower part. Radial direction and axial breathing. The upper furnace pipe adopts double layer steel structure and countercurrent air supply mode. The lower furnace pipe is made by processing integrated heat resistant steel in flange, fin and inner wall in wearing parts. The operation life is over 3000h. There is radiating rib of heating air on the edge of furnace pipe liner by using the heat of casting cupola to heat air in cupola. Hot air temperature is about 180-250℃, which contributes to improve trhe thermal efficiency of production equipment, decrease production cost and improve economic benefit of enterprises.

- Q: What's the heat conductivity coefficient, specific heat capacity and density of the refractory material of magnesite-chrome brick and magnesia-alumina brick respectively?

- It is suggested that you find some samples of well-known manufacturers, such as Ogilvy and Mather Group, and that will be more correct.

- Q: Which brand of refractory fiber hard thermal insulation board is better?

- Thermal insulation materials are divided into two types: porous material and heat reflecting material. The former uses the air void contained in the material to maintain thermal insulation itself for the heat conductivity coefficient of air or inert gas within the voids is low, such as foam material, fibers and other materials; the latter material has a high coefficient of reflection which can reflect the heat, such as gold, silver, nickel, aluminum foil or metallic coated polyester and polyimide thin films. Aerospace industry has strict requirement for the weight and volume of thermal insulation material, and it is often also required to has the properties of noise absorption, vibration attenuation, and anti-corrosion. Different aircrafts have different requirements for thermal insulation materials. Aircraft cabin and cockpit usually use foam, ultra-fine glass wool, high silica cotton to maintain thermal insulation. Earlier missile head uses phenolic foam plastic as thermal insulating material. With the application of polyurethane foam with good thermal endurance, the single insulating material has been developed to sandwich construction. A few millimeters foaming coating is coated on the skin outside the missile instrument bay, it is anti-corrosion coating at room temperature and when aerodynamic heating reach 200 ° C or more, it will generate foam evenly thus maintaining thermal insulation. Artificial earth satellite moves in an environment where the temperature varies from high to low, so it must use laminated thermal insulation material with high reflecting performance, which is usually made up of dozens of layers of aluminum film, aluminized polyester film, and aluminized polyimide film. In addition, the successful development of the surface thermal insulated tiles has solved the problem of thermal insulation of the space shuttle, it also marks a higher level of development of insulation materials.

- Q: what is the specs of thermal insulation refractory slab ?

- fireproof?panel is also called refractory slab, which refers to a layer of veneer. Its thickness is generally about 0.8 mm and there is a veneer made after compression of surface layer of paper, colored paper and multilayer kraft paper. Wear-resistant, heat-resistant and fire-resistant properties, scratch resistant and easy to clean, rich colors and good stability.

- Q: What are the commonly used admixture for alumina-magnesia refractory? What are the impacts on its performance?

- 2, form Mg-SiO2 coagulation and combination, CA cement bond? Bricks can generally be made by combing with phenolic resin, castable use 1, combined with silicon powder; 3, can also combined with brine MgCl is binding agent

- Q: Who can tell me the properties and classification of insulating refractories?

- The refractory materials refers to the refractory material of high porosity, low volume density, low thermal conductivity of the insulating material. Also called lightweight refractories. It includes insulating refractory products, refractory fiber and refractory fiber products.The characteristics of insulating refractory material is of high porosity, generally 40% to 85%; the volume density is low, generally less than 1.5g/cm3; the thermal conductivity is low, generally less than 1.0W (M - K). It is used as the insulation material of industrial furnace, furnace can reduce heat loss, save energy, and reduce thermal insulation equipment weight. The mechanical strength of refractory material, abrasion resistance and slag resistance is poor, should not be used for load-bearing structure of furnace slag, furnace, and direct contact with the molten metal and other parts.

- Q: What's the fire endurance of A grade fireproof glass curtain wall?

- The following is fire endurance of A class fireproof glass curtain wall. Fire endurance of the fire window: A class fire window: no less than 1.2h; B class fire window: no less than 0.9h; C class fire window: no less than 0.6h. Technical requirements: 1. Materials and fittings: (1) Window frame should adopt the steel frame or wood frame with certain strength so as to guarantee the integrality and stability of the fitting; (2) Steel frame and mound layer can choose the galvanized steel sheet or stainless steel sheet. Its selection standard is in line with provisions of Article 5.1 in GB12955 "General Technical Requirements on Steel Fire Doors"; (3) Selection standard of wood frame and mound layer should be consistent with the provisions of Article 5.1.1 in GB14101 "General Technical Requirements on Wood Fire Doors"; (4) Filler material inside the steel frame and wood frame should be incombustible material; (5) Fireproof glass can choose the qualified product with no influence on the fire resistance test of the fire window, and its light transmittance should be no less than 75% of that of the ordinary sheet glass with the same layers; (6) Sealing material between the frame and the fireproof glass should use flame retardant material which can play the role of fire prevention and smoke insulation in case of fire. Hope it's helpful for you.

Send your message to us

Electrofused Magnesite Refractory Basic Fused Magnesite

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords