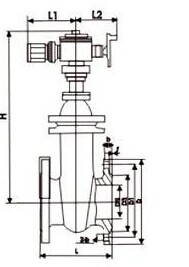

Electric cast steel Gate Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Soft seal gate valve

Size:DN40mm-600mm

Design standard: DIN 3352/BS 5163/AWWA C509/JIS B2043

Test standard: DIN3230/BS 6755/AWWA C509/JIS B2003

End flange standard: DIN 2533 PN16/BS 4504 PN16/ANSI 150LB/JIS B2212 10K

Face to face standard: DIN 3202 F4/DIN 3202 F5/BS 5163/ANSI 16.10/JIS B2002

Body: Ductile iron/GGG50/A536

Wedge: Ductile iron+EPDM/Ductile iron+NBR

Stem: Brass/SS416/2Cr13

Bonnet: Ductile iron/GGG50

Handwheel: Ductile iron/GGG50

The products are widely used in water source projects, urban water supply and drainage, sewage treatment, eletric power, petroleum, petrochemical, heat supply, shipbuilding, medicine and metallurgy industries. Equipment are used for regulating or cutting off media in pipelines. Suitable media include water sewage, sea water, air, foodstuff and oil. Suitable for gear operators, electric and pneumatic control actuators.

- Q: Valve flange drawing n- up to what

- A bolt hole used to indicate a flangeThe value of N indicates the number of bolt holesUp to the numerical representation of bolt hole size

- Q: Why is gate valve or butterfly valve used for water pump?

- General pressure is small, use the butterfly valve, when the pressure is big, use the gate valve. The two main function of the valve is to adjust the flow and easy to overhaul.Zibo Boshan new Duke water supply equipment

- Q: Z45T-10 what kind of material is the gate valve?

- Cast iron, sealed with copper alloy inside. Shanghai Yu Cheng fluid on the professional production of this thing,

- Q: Why? God, can you explain to me in detail why?

- The exit of the general pump is the first soft connection (shock absorber), followed by the check valve, and then the partition valve (such as butterfly valve, gate valve, cut-off valve, etc.), this is not the final answer.The question is interesting, and no corresponding information has been found in the relevant standards. We have also discussed the related issues, but differences of opinion is relatively large, the advantages of 1, first installed check valve installed after the valve or butterfly valve, check valve, can be protected, especially in a parallel pump, when the pump does not start, another pump starts when the impact force is gate valve or butterfly valve bear, disadvantages: gate valve or check valve who will protect? There have been a case of butterfly valve is broken. 2, first installed gate valve or butterfly valve installed after the check valve, advantages: can protect the butterfly valve or gate valve, the impact on the check valve to bear. Disadvantages: check valve who will protect, check valve by pressure difference switch, if the high pressure high pressure pipe, pump, if the flow is not stable, so check valve will repeatedly switch, will affect the check valve life. Personal opinion: check valve, check valve performance now have changed, many are using the slow closing check valve, so the impact force is two aspects to bear, because exports are not fully open the valve or butterfly valve, so you can put in check after the gate valve or butterfly valve valve. If not the slow closing check valve installed in the valve or the best after the butterfly.

- Q: Installation and operation instructions of knife gate valve

- 1. knife gate valve installation, check the valve cavity and sealing surface and other parts, not allowed to dirt or sand adhesion;2. bolts of connecting parts must be tightened evenly;

- Q: Gate valve z45h-10dn250 length of the body?

- Z45h-10dn250 body length L=330mm, this valve is hidden bar, elastic seat, sealing gate valve, gate lining, lining fluorine, belong to soft seal

- Q: What kind of valve is gate valve? Is it different from the cut-off valve?

- Gate valve is applied to the big diameter pipeline valve, the valve is generally used in small pipe diameter pipeline, their internal structure is different, the valve can not regulate the flow of water, the valve can be. If you want to understand in detail, it is recommended to take a sample of valve manufacturers to see the internal structure.

- Q: What does gate valve DN80-PN16-QT450 mean?

- The outer diameter of the pipe is usually 89mm;"PN16" means the nominal pressure of the gate valve is 16Mpa;QT450 QT said, nodular cast iron, tensile strength is more than 450MPa 450.

- Q: Acid resistant alkali valve gate valve

- A products have few connections and good overall steel quality.B closure speed is fast.C opening limit mechanism is convenient, flexible and precise.

- Q: What are the standards for the execution of cast iron dark pole gate valves?

- Three, cast iron gate valve structure features:1.. The structure is simple and compact, the design is reasonable and novel, the rigidity of the valve is very good, the passage has a large flow area, the medium is unimpeded, and the resistance is small;2., the sealing surface of the material selected carbide and stainless steel, has a reliable sealing performance, long service life;3. cast iron dark rod gate valve using graphite material for packing, easy to operate;4., can use a variety of driving methods, such as manual, electric, pneumatic, gear drive, etc.;5., the position of the two sides of the gate valve is symmetrical, so the medium can flow freely on both sides, and the installation is very convenient;6. cast iron hidden rod gate valve structure length is short, the quoted manufacturing process is good, the scope of application is very wide;

Send your message to us

Electric cast steel Gate Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords