Electric Ball Valve Side Entry Design, Top Entry Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

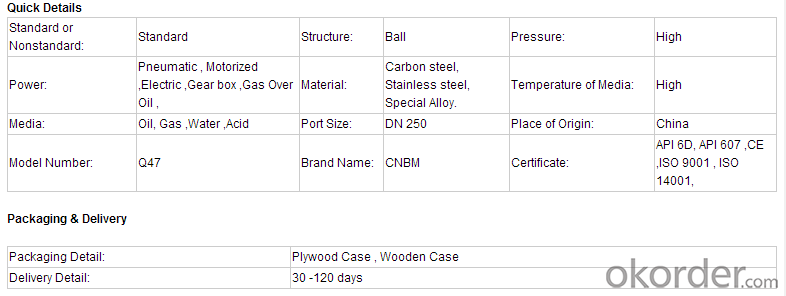

Specifications

Side Entry Design, Top Entry Design.

Bolted Body Or Fully Welded Body.

Full Bore Or Reduced Bore.

Size: 2"- 40", DN 50-1000mm

Pressure: 150 -1500LB, PN 10-40

Material: Carbon steel, Stainless Steel, Special Alloy.

Electric Ball Valve

Design Feature:

Side Entry Design, Top Entry Design.

Bolted Body Or Fully Welded Body.

Full Bore Or Reduced Bore.

Flanged End Or Welding End.

Double Block and Bleed.

Locking Device.

Single Piston Effect, Double Piston Effect.

Automatic Internal Relief of Body Pressure.

Emergency Sealant Injection System.

Fire Safe Design. Antistatic Device.

Anti-Blowout Stem Design.

Body Vent Device.

Stem Extension for Underground Service.

Product Range:

Size: NPS 2”~ 40” , DN 50-1000

Pressure Rating: Class 150 -1500 LB , PN 10~40

Design standard : API 6D , EN13942

Face To Face Dimension : API 6D , EN 558-1, EN 12982

Connecting Dimensions: ASME B16.5, ASME B16.47, ASME B 16.25, EN 1092-1, and EN 12627.

End Connection: Flange, BW.

Body Materials: Carbon steel, Stainless Steel, Special Alloy.

Medium: Natural Gas, Oil, Steam

- Q: Ball valve specifications are represented by 2 FF,

- FF refers to the form of connection between the valve and the pipe lineFF, or Flat Face, is a common form of flat flange connection

- Q: DN15 stainless steel ball valve 304 can withstand much pressure?

- There is no pressure rating PN (nominal pressure) in the description, so it is not sure how much pressure it can bear.PN, nominal pressure (Nominal, Pressure) is a means of pressure, mainly used in piping and pipe fittings, valves and other shell device pressure expressed;Nominal pressure PN is a digital indication of pressure related signs, which is a convenient round integer for reference.

- Q: The hot water pipe ball valve what brand alone?

- Angle valve is mainly suitable for heating pipes. Usually a connecting point between the hose and the wall that is attached to the wall and attached to the faucet above.

- Q: For the master enlighten Q47 ball seat spring hole number is determined by how

- Force = spring stiffness (kg/mm) * compression volume (mm)Number of work cycles of spring stiffness = line diameter *1000/C 3 timesC= spring middle diameter / line diameterSpring diameter = spring outside diameter line diameterCalculate each spring force, multiplied by the number. According to the manual valve design must be greater than the pressure, pressure ratio must be large than the material allowable pressure on the line. (emphasize that here because the production process of the spring, has value of many uncertain factors, so the actual production of the spring and you cannot calculate out the same, so please choose when to consider).

- Q: What's the difference between a ball valve and a butterfly valve? Which one has better sealing performance?

- The structure of valve and butterfly valve, and determines the price of the different use of the environment. The same nominal diameter of the butterfly valve and ball valve has the advantages of simple structure, low cost, adjustable range, liquid and gas valve is usually applied to non particulate impurities like fluid, small pressure loss, good sealing performance, high cost. Generally speaking: small caliber election ball valve, large caliber butterfly valve.

- Q: Stainless steel ball valve Q41F-16P DN80 weight is

- The whole diameter is about 40kg heavyThere is a slight difference between the manufacturers

- Q: What type of ball valve is Q17F-10T?

- I don't know. Oh, I haven't seen it yet

- Q: Stainless steel ball valve, Q11F-10P, 16P, 11F, what does that mean?

- The first 1 that connect the second ball, 1 straight through valve, F PTFE sealing.

- Q: What does "41H" mean in the ball valve Q41H-16?

- Q- ball valve;4- flange connection;1- through flow channel; (structural form)H-Cr13 stainless steel; (material)16- nominal pressure; (1.6Mpa)Body material: WCB, A105This is manual, and the valve body is WCB.

- Q: What does "q341" and "q347" mean?

- Q341 is a turbine driven flange straight through floating ball valveQ347 is a turbine drive flange through fixed ball valveShintex valve0577Eight thousand six hundred and ninety-oneSeven thousand five hundred and sixteen

Send your message to us

Electric Ball Valve Side Entry Design, Top Entry Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords