Ductile and Casting Iron Manhole Cover C250 D400 EN124 in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 kg

- Supply Capability:

- 3900 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

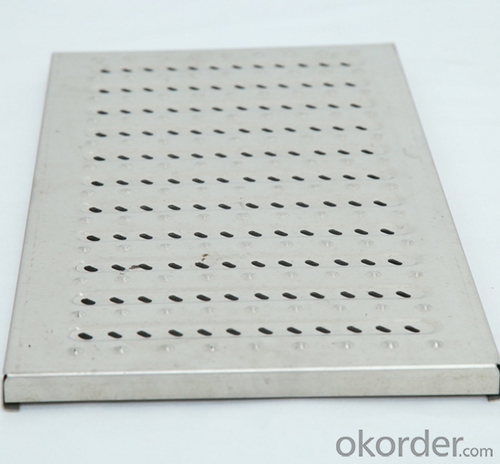

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Sand casting

5).we can produce as per customers'drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| CCUC30HK | C250 | 200*200 | 300*300 | 34 | 8.2 |

| CCUC40HK | C250 | 303*303 | 400*400 | 35 | 14.5 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. What is your minimum order requirement?

A: We will indicate the MOQ for each item in the quotation sheet. we accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

3. Can I get free samples?

A: Yes, we can provide the free samples, but you need to bear delivery freight.

4. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your requirement, but it maybe let your purchasing cost changed also.

- Q: What are the casting parts used to test shrinkage holes?

- 2. x ray. This method can do nondestructive testing, but the cost is higher. Generally, high castings are required.

- Q: What are the factors affecting the machining process of the casting material and structure?

- Medium carbon steel begins, and the casting can not be punched and tapped directlyStainless steel, ordinary grade (Fe based alloy element content, less) can not do heat treatment. But processing small holes or tapping to heat treatment (solution. In practice, the annealing treatment can also be). There are a lot of stainless steel matrix is not to say, for example, nickel, cobalt and tungsten. And so on.

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Those should be head prints. If required, it would be better to throw with a single grinding head.

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- 1, qualified enterprises will directly iron ore into molten iron, and then poured into the mold, such a good product performance. I work in the cast iron industry, which I can tell you for sure.2, this, like the Great Wall Motor Company has its own parts production department, as well as the corresponding mold center, so it will be their own casting. If the manufacturer does not have these departments, they can only place orders for others to do.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- You need to confirm what you use tap processing, so as to determine the size of the casting hole

- Q: Casting parts have poor surface finish. What sand is used to make them?

- V casting, EPC, precision casting of the surface is good.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Not processed, do not understand your problem... There's something wrong with the drilling machine. Please call me

- Q: What are the general technical requirements for casting parts?

- According to the national standard GB/T 9438, there are 8 aspects: 1. chemical composition; 2. delivery status; 3. mechanical properties; 4. dimensional tolerances; 5. weight tolerances; 6. appearance quality; 7. internal quality; 8. casting salvage.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- Processing stainless steel materials, you can use YG class tools, such as YG8, YG8N. The tool geometric parameters g0=15 degrees to 18 degrees, a0=6 degrees to 8 degrees, kr=75 degrees, ls=-5 degrees to -8 degrees; cutting amount is Vc=43 m/min, ap=0.3 to 0.5 mm, f=0.16mm/r.

Send your message to us

Ductile and Casting Iron Manhole Cover C250 D400 EN124 in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 kg

- Supply Capability:

- 3900 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches