Double Sides Glossy Color Pvdf Aluminum Composite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Double Sides Glossy Color Pvdf Aluminum Composite

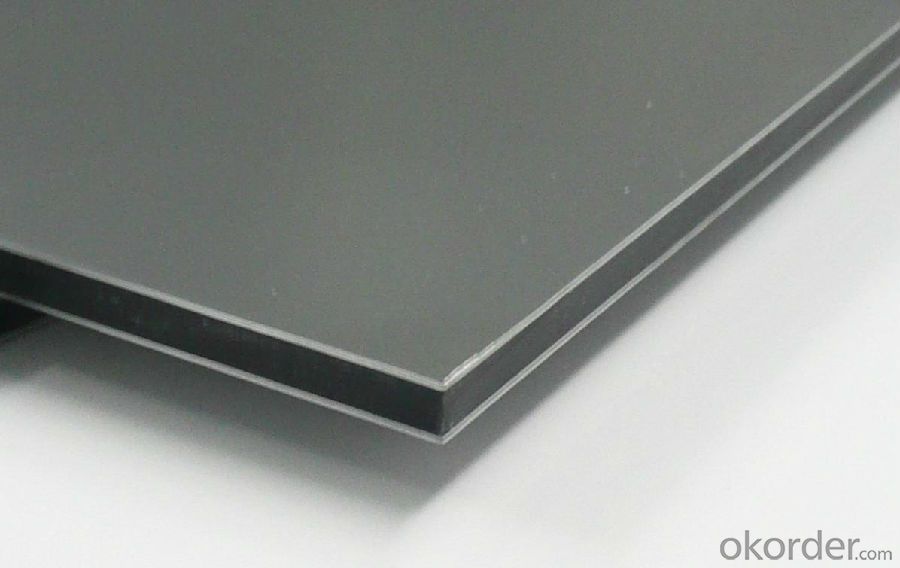

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

7) Industrial materials, materials for vehicles and boats

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Coating line | WANGUAN | 2 | 4.5 | Acceptable |

| Aluminum plastic composite line | FB1600 | 4 | 3.5 | Acceptable |

| Embossing line | No information | 1 | 1.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Bending machine | No information | 1 | 8.0 | Acceptable |

| Visual comparison of the colour device | MSBS-1 | 1 | 5.0 | Acceptable |

| Drying oven | PULUO | 1 | 5.0 | Acceptable |

- Q: Cast aluminum plate how to deal with a small hole

- Aluminum welding, you are there is a stomatal, welding process is not handled well. Strength certainly not reach, not to mention performance. There is no picture, look at the defect situation, I see can not remedy, think of ways to achieve its initial use of performance. Cast iron are recognized as difficult to weld it, this is a large cast iron machine arm after the fracture of the arm, the use of the scene, the accuracy of performance did not damage

- Q: Useful aluminum-plastic plate production line made of steel and aluminum did not?

- Use of aluminum-plastic plate production line made of steel and aluminum ??

- Q: Which bathroom cabinet is better? What kind of material is better

- Can come I love my home network to see, which is a special furniture buy, bathroom cabinet what the building materials everything, and buy form, it is recommended to see

- Q: Meizhou how to sell outdoor aluminum plate? Please contact the contact, QQ and so on

- Located in Shunde: Guangdong Li Kyle Industrial Co., Ltd. specializing in the production of "Lee Kyle card" "Auspicious licensing" aluminum-plastic panels, aluminum veneer. Contact in space.

- Q: Aluminum-plastic curtain wall construction in winter, with the real paste can you?

- Another winter weather should also be divided into regions, such as the winter of winter and winter in Hainan,

- Q: How to install the aluminum-plastic panel ceiling?

- The more common installation method is to directly through the self-tapping screws in the aluminum plate above the keel, so there will be nail caps, but can be secretly fight. This is relatively easy.

- Q: OKorder 3M glass curtain wall adhesive tape and aluminum-plastic plate Lvkou Ban and aluminum veneer special double-sided tape where there?

- US 3M company in OKorder designated agent 3M tape and glue labels and other products distribution and double-sided tape cutting and precision cross-forming! My company's tape has a professional curtain wall with double-sided adhesive.

- Q: Will the aluminum curtain wall refers to the metal aluminum curtain wall, or aluminum veneer aluminum-plastic curtain wall?

- In general, aluminum curtain wall refers to the aluminum veneer curtain wall, but now also refers to the aluminum honeycomb curtain wall, you can according to your needs to find suppliers, if the need for aluminum veneer, aluminum honeycomb products can find Reynold Aluminum veneer manufacturers, their product quality is very good oh

- Q: What is good for plastic and plastic?

- General cooked rubber is more tough, raw rubber is not high temperature, the melting point is low, the melting point of 80 degrees or so, poor elasticity, fragile. Sika high temperature, melting point of about 120 degrees, better elasticity. , Softer for the cooked rubber.

- Q: The status of aluminum - plastic plate products

- Aluminum-plastic curtain wall products as a kind of aluminum curtain wall products, and single-layer aluminum curtain wall and honeycomb aluminum curtain wall, compared with easy processing performance, economical and practical, excellent quality and a series of advantages, is the most widely used aluminum curtain wall products, The largest variety. It is the series of advantages of aluminum-plastic curtain wall, which has led to the development of aluminum-plastic curtain wall in China for more than ten years. Figure 3 for our own design, processing, installation of aluminum-plastic curtain wall project. However, the current situation of aluminum-plastic curtain wall in China and revealed a series of problems, many of them are also caused by the abuse of these advantages.

Send your message to us

Double Sides Glossy Color Pvdf Aluminum Composite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords