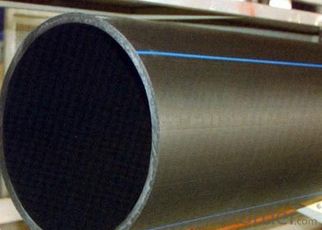

DN500mm~1200mm HDPE Plastic Tubes for Water Supply

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Parameter

Name | duplex stainless steel pipe price | |

Certification | TUV ISO | |

Standard | GB HG ASME/ASTM EN JIG AISI etc. | |

Size | Outer Diameter | 19-3000 mm |

Thickness | 1-100 mm | |

Length | 6m 12m and other size that could be | |

tailored to customer | ||

Grade | 200 Series (Cr - Ni - Mn austenitic stainless steel) mainly: 201,202 | |

300 Series (Cr - Ni austenitic stainless steel) mainly: 301,302,303,303 CU, | ||

304,304 L, 304F, 304H, 310,310 S, 314,314 L, 316,316 L/321 | ||

etc. | ||

400 Series( Cr martensitic/ ferritic stainless steel ):410,420,430,409L etc. | ||

Raw Material | Tisco | |

D.K.C | ||

ZPSS | ||

Bao Steel | ||

Outokumpu | ||

Nippon Steel | ||

Shanghai Krupp | ||

Huzhou Yongxing | ||

Application | petrifaction | |

chemical industry | ||

papermaking | ||

medicine | ||

military industry | ||

sea water desalination | ||

shipbuilding | ||

mechanical equipment | ||

fluid transportation | ||

Production Line | φ273 * 10~ φ630 * 16mm automatic continuous production line | |

φ89~φ219*11mm automatic continuous production line | ||

ZG50 ZG60 small diameter automatic continuous production line | ||

UOE production line | ||

Testing | nondestructive testing | |

hydrostatic test | ||

intergranular corrosion | ||

x-ray detector | ||

eddy current testing | ||

the surface quality | ||

other related testing | ||

Packing | Plastic bag for each piece then packed in standard seaworthy woven | |

bags .Wooden or steel crates could be tailored to customer when requested. | ||

Material Composition (%) | TP304 (S30400) | |

TP304 Chemical Composition of | C | 0.08 |

Mn | 2.00 | |

P | 0.045 | |

S | 0.030 | |

Si | 1.00 | |

Cr | 18.0~20.0 | |

Ni | 8.0~11.0 | |

、

FAQ

Q: What the Raw material ?

A: We use 100% Korea material.

Q: What is your MOQ?

A: As customer's request.

Q: What is the production ability ? or delivery time ?

A: Our production ability support 40HQ order finish in one week.

Q: What is the regular shipping port ?

A: Shanghai or Yangzhou

Q: What is your payment ?

A: TT or LC

Q: Can we have sample ?

A: Sample free, freight cost you.

Q: For urgently doubuts, who online ?

A: Sales and marketing Manager 24 hours online service.

- Q: I have forgotten the name of the breed altough i know it starts with sy. I just want to know if they can fit in a tube cage or will they get stuck? And what is the best breed to get if you do have a tube cage?

- Syrian hamsters, the larger breed of hamster, can outgrow the tubes and get stuck. Dwarf hamsters are better suited for those types of cages. If you're interested in a syrian hamster, a large, basic wire cage is probably a good idea. A bin cage is also a good cage to have for hamsters.

- Q: Can plastic tubes be used for roller coasters?

- Plastic tubes can potentially be used for roller coasters, specifically in the construction of track components such as supports, guide rails, or even the coaster cars themselves. However, the feasibility and safety of using plastic tubes would greatly depend on various factors such as the specific type and quality of plastic used, engineering requirements, load-bearing capacity, and overall design considerations.

- Q: What are the common wall thicknesses for plastic tubes?

- The common wall thicknesses for plastic tubes can vary depending on the application and manufacturing process. However, some typical ranges include 0.5mm to 2mm for thin-walled tubes, 2mm to 5mm for medium-walled tubes, and 5mm to 10mm for thick-walled tubes.

- Q: i have an amp installation kit, with a 0 gauge power wire, i'm assuming since there is no split loom tubing that came with the complete kit, that it will be unnecessary because the power wire is so thick?

- I'd protect it further - Especially if it goes thru sheet metal or outside the passenger compartment. I've run power feed wire thru plastic tubing, when it is under the body, just to be safe.

- Q: How are plastic tubes filled with products?

- Plastic tubes are typically filled with products through a process called tube filling. This involves the use of specialized machinery that dispenses, measures, and seals the desired product into the tubes. The process may vary depending on the type of product being filled, but it generally involves automated or manual filling stations that accurately measure and fill the tubes. Once filled, the tubes are sealed, labeled, and packaged for distribution.

- Q: How are plastic tubes filled with creams or gels?

- Plastic tubes are typically filled with creams or gels using a process called tube filling. This involves the use of a machine that pneumatically or mechanically fills the tubes with the desired product. The tubes are first loaded onto the machine, and then the product is pumped into them through a nozzle. The machine ensures accurate and consistent filling by controlling the amount of product dispensed into each tube. Once filled, the tubes are sealed and can then be labeled and packaged for distribution.

- Q: Can plastic tubes be used for storing petrochemicals?

- Yes, plastic tubes can be used for storing petrochemicals. Plastic tubes made from materials such as polyethylene or polypropylene are commonly used for storing and transporting various petrochemicals due to their resistance to corrosion and chemical degradation. These tubes provide a cost-effective and reliable solution for safely containing and preserving petrochemical substances.

- Q: Can plastic tubes be used for DIY crafts?

- Yes, plastic tubes can definitely be used for DIY crafts. They are versatile and can be easily cut, shaped, and decorated to create various projects such as flower vases, pen holders, jewelry organizers, or even as components for sculpture making.

- Q: What are the different types of closures available for plastic tubes?

- There are several different types of closures available for plastic tubes, including screw caps, flip-top caps, snap-on caps, pump dispensers, and squeeze caps. Each closure type offers different functionalities and is suitable for various applications.

- Q: How are plastic tubes labeled for identification?

- Plastic tubes are typically labeled for identification using various methods such as printed labels, adhesive tapes, color coding, or embossed markings.

Send your message to us

DN500mm~1200mm HDPE Plastic Tubes for Water Supply

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords