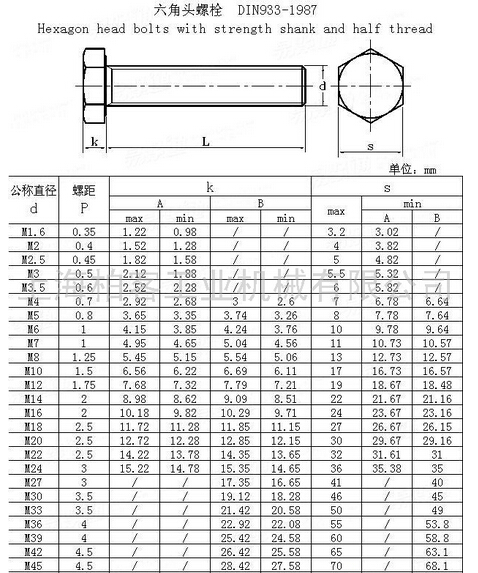

DIN933 Hexagon Head bolts M4-M22

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name | DIN933 Hexagon Head bolts M4-M22 |

Material | Carbon Steel, Stainless Steel 201/ 304/ 316 or others. |

Size | M4--M22 |

Standard Model | DIN ANSI JIS ASTM |

Min Order | 1000piece/ pieces |

Packaging & Shipping

Packing | Inner Box + Carton Box + Pallet or Under Your Requirement |

Supply capacity | 10000000 piece/ pieces per month |

Delivery time | 5~20 days after deposit |

Export market | Asia, America, Europe, Africa, markets. |

Our Services

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Picture:

- Q: Screw hole slip wire how to do?

- In the screwdriver head pad things such as double-sided adhesive, non-woven fabrics, etc. If there is no condition, then the paper can also

- Q: Why do you have to add a spring washer when it comes to the role of ah ah ah

- The main function of the spring washer in the mechanical design, production to prevent the nut (or bolt) automatically loose, and even force.

- Q: Why should the screw twist clockwise?

- Clockwise tightening of the screw is called orthodontic screw, counterclockwise tightening of the screw called anti-screw or left teeth screws, the general international are clockwise orthodontic screws, in a particular case will use the left teeth Screws, such as the need to fix the fan impeller, are left teeth

- Q: What is a self-tapping nail? Is it used? What are the characteristics of the shape? What is the difference with ordinary screws?

- Self-tapping screws are in the metal or non-metallic materials in the pre-drilling in the self-drilling with a threaded thread with a threaded fastener. Self-tapping screws with high tension, single, unilateral combination of features. Self-tapping screws are used for connection between thin metal plates (steel plates, saw boards, etc.). When connecting, first thread the bottom of the connector, and then screw the tapping screw into the threaded bottom hole of the connected part. As the tapping screw thread surface has a high hardness (≥ 45HRC), can be connected to the threaded bottom hole in the internal thread, thus forming a connection.

- Q: For the commonly used standard parts, for some of the quality of good or bad, how to distinguish,

- If it is important, random to do one or two destructive pull test, their own press with a simple tooling, pay attention to safety, if their own, to the physical and chemical test units or heat treatment of the brothers can do. You can also go to the supplier to monitor the sampling of such a similar test (contract agreed).

- Q: Is it hard to heat the fasteners?

- Fasteners are also known as standard parts, which are mainly heat-treated according to the material of the product.

- Q: Are there categories of fasteners classified by material?

- Mainly carbon steel, alloy steel, stainless steel, other materials category

- Q: Please understand the friends of the self-tapping nails, screws, nuts production process, is the manufacturer's process. The more specific the more detailed the better

- According to the screw nut and thread size custom the corresponding mold, mold is done into the material, then the head - rubbing - surface treatment - the packaging is complete.

- Q: Stud that head or nut that ah, I need to have the authority of the provisions of the document, please know that the prawns are told, thanks to!

- The main purpose of the elastic cushion is to prevent loosening, which is added at the end of the screw, and the screw nut is arranged on the side of the nut.

- Q: Our company to purchase a number of fasteners to see when the CAD drawings in the technical requirements I do not know the specific to write those content

- Fasteners are generally standard parts, have national standards (except for special requirements)

Send your message to us

DIN933 Hexagon Head bolts M4-M22

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords