Desiccant Masterbatch Defoaming Agent Anti-foam Agent for PP/PE Recycled Plastic Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

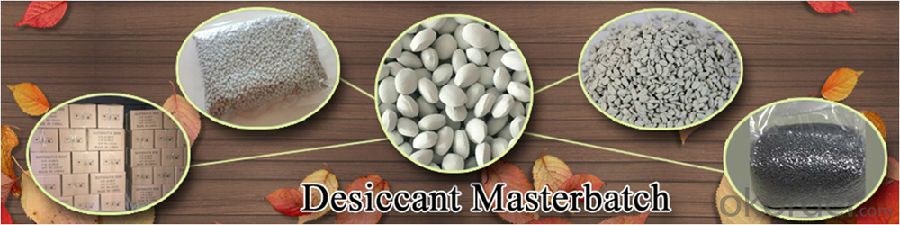

Desiccant masterbatch (also called defoaming agent, anti foam agent ).

It is suitable for all kinds of enterprises which make product with PP/PE recycled plastic material.

The bubble ,moire fringe, crack ,stain problems will be solved by adding efficient anti-foam masterbatch .

Application Method:

Production process can be achieved by mixing this masterbatch with damp plastic materials symmetrical. 1%--2% amount is recommended in blow molding,2%-5% is recommended in sheet and injection molding.

Customers decide the amount according to the condition of plastic dampness.

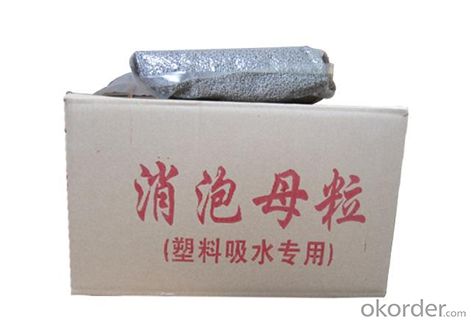

Packaging:Vacuum package, 2.5kg or 5 kg of each, it can not be store open,keep out of sunny peacan.

Advantage of Desiccant Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Desiccant Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

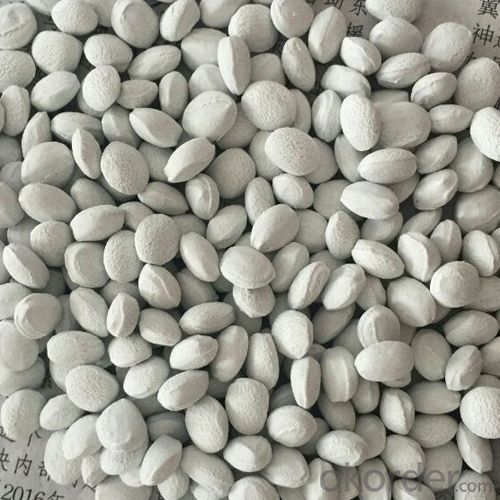

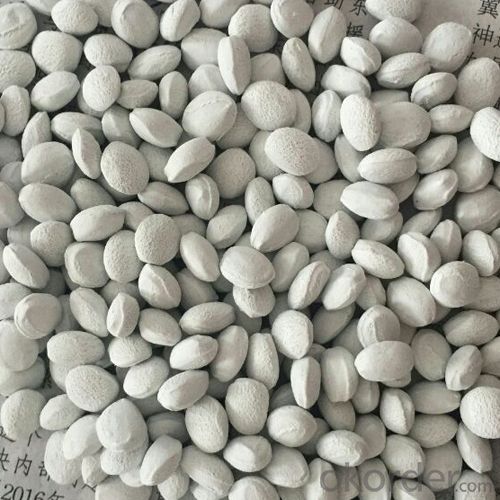

Product Pictures of Desiccant Masterbatch:

- Q: How many kinds of raw materials are there for blowing plastic bottles?

- Plastic bottles are made of polyethylene or polypropylene and added a variety of organic solvents. Plastic bottles are widely used in polyester (PET), polyethylene (PE), polypropylene (PP) as raw material, add the corresponding organic solvent after high-temperature heating, the plastic mold by blow molding, extrusion blow or injection molding of plastic containers.

- Q: How do plastic raw materials trade? How big is the market?

- The transaction is mainly based on the traditional trading model and the Internet trading model 2.

- Q: What are the raw materials for plastic products? Resin or oil?

- There is no definite classification of plastics at present. The general classification is as follows: 1.. According to the physical and chemical properties of plastics, thermoplastics can be repeatedly heated, softened and cooled to harden in a certain temperature range. Such as polyethylene plastic, PVC plastic.Thermosetting plastics: Plastics cured by heat or other conditions without melting into insoluble material. Such as phenolic plastics, epoxy plastics and so on

- Q: What is the difference between ABS plastic raw materials and recycled materials? Or how to distinguish between raw materials and recycled materials?

- Raw material is crude oil refining, renewable materials are garbage recycling, and some will have additives in the regeneration. If it is not cleaned, there may be impurities.

- Q: How to identify the proportion of nozzle material in plastic?

- This result has two conclusions: 1, with large ratio of feed back. 2, the molding process causes the plastic cracking phenomenon to be more serious. The following is a screenshot of the performance of the material. It is important to note that the same plastic has different data downstream of different test conditions, so it is necessary to refer to the test conditions on the physical chart.

- Q: What raw material (HDPE) made of plastic bags, high transparency, good sense of light master?

- Fillers, also called fillers, can improve the strength and heat resistance of plastics and reduce costs. For example, adding wood powder to phenolic resin can greatly reduce the cost, and make phenolic plastic one of the cheapest plastics, and can also significantly improve the mechanical strength. Packing can be divided into two kinds of organic fillers and inorganic filler, the former such as wood powder, rags, paper and all kinds of fabric, the latter such as glass fiber, diatomite, asbestos, carbon black.

- Q: What kind of plastic material is used for medical instruments?

- Because most monomers and their oligomers are poisonous, medical plastics have strict restrictions on the residues of these substances;

- Q: Application of CPE in plastics industry

- Chlorinated polyethylene (CPE) for saturated polymer materials, the appearance of white powder, non-toxic and tasteless, has excellent weather resistance, ozone resistance, chemical resistance and aging resistance, good oil resistance, flame retardancy and coloring properties.

- Q: How about the price of plastic raw materials now?

- ABS market overall stability, part of the small move.

- Q: What are the bulk density, size and moisture content of the general plastic material?

- Among them, the mass of the material has nothing to do with the particle size, but the larger particles have larger volume due to the presence of more voids between the particles. Small particles (powder) to the general packing is very tight, so the smaller bulk density.

Send your message to us

Desiccant Masterbatch Defoaming Agent Anti-foam Agent for PP/PE Recycled Plastic Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords