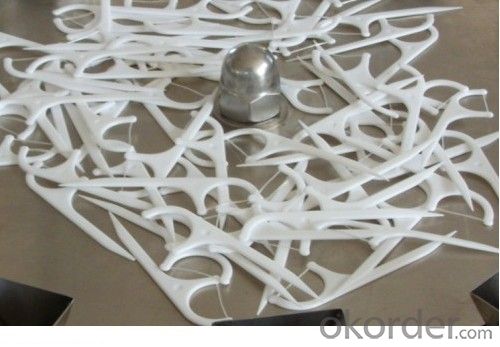

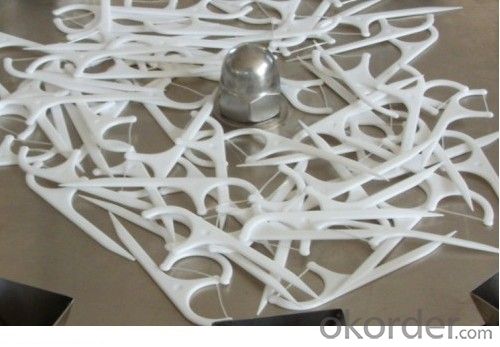

Dental floss injection molding machine car windows on the sealing strip

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 g/m

- Supply Capability:

- 100 g/m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specializing in the production of car windows on the sealing strip

FT-300 规格表 Specifcatiom

| MODEL | Unit | FT-300 | ||||

| Injection System | Screw Diameter | mm | 28 | 30 | 32 | |

| Injection Pressure | kg/cm | 1750 | 1552 | 1325 | ||

| Max.Shot Weight(PS) | g | 65 | 75 | 90 | ||

| Max.Shot Weight(PS) | OZ | 2.2 | 2.5 | 3 | ||

| Screw Stroke | mm | 120 | ||||

| Screw Speed Max | rpm | 0-205 | ||||

| Nozzle Contact Force | tons | 2.5 | ||||

| Nozzle Retraction Stroke | mm | 140 | ||||

| Number of Temperacture Control | - | 3 | ||||

| Material Hopper Capacity | L | 15 | ||||

| clamping system | Clamping Force | tons | 35 | |||

| Platen Size | mm | 520×370 | ||||

| Distance Between The Bare | mm | 350×200 | ||||

| Min.Mold Height | mm | 150/210 | ||||

| Opeing Stroke | mm | 180 | ||||

| Max.Opening Daylight | mm | 350/400 | ||||

| Ejector Force | tons | 1.5 | ||||

| Ejector Stroke | mm | 95 | ||||

| Hydraulic power system | Max.Hydraylic Pressure | kg/cm2 | 150 | |||

| Pump Output | L | 41 | ||||

| Oil Reservoir Capacity | L | 150 | ||||

| Cooling Water Consumption | L/hr | 600-800 | ||||

| Pump Motor Power | kw | 5.5 | ||||

| Barrel Heating Power | kw | 3.5 | ||||

| Total Weight | kw | 9 | ||||

| Others | Machine Weight | tons | 2 | |||

| Machine Dimensioms(L×W×H) | m | 1.6×1.3×2.7 | ||||

| Shipping Weight | tons | 1.5 | ||||

| Shipping Measurement(L×W×H) | m | 1.8×1.6×1.8 | ||||

Above spec sheet, if design changes without notice!

- Q: Dr. oil mill, bag filter, instructions for use

- Working principleThe vacuum oil filter is designed according to the different boiling points of water and oil. It consists of a vacuum heating tank, a fine filter, a condenser, a primary filter, a water tank, a vacuum pump, an oil drain pump and an electric cabinet.

- Q: I use the 300 frame oil filter to filter the oil. What size filter paper should I use?

- Compression method manual screw compressionThe ambient temperature of -25 to 70 DEG CThe medium temperature -25 to 90 DEG CPower 380V/50HZ (three-phase four wire) or according to customer needsThe noise is less than 70dBMotor power (KW) 5.5 KWThe inlet and outlet diameter is 60 mmEquipment weight 600KgOutline size 1600mm * 600mm * 1100mmThe continuous working time is more than 150hMTBF > 5000h

- Q: How to assemble and disassemble the vacuum pump for power generation oil filter?

- In fact, if you understand the machine, it is easy to assemble and disassemble, but in order to avoid unnecessary trouble,

- Q: Where has the waste lubricating oil to come in, it is the oil filter of the finished oil

- Waste lubricating oil is used after the deterioration has been unable to use the oil, oil filter main machine is mainly pure physical filtration, filtration, filtration, removal of impurities of water gas, waste oil emulsion breaking, can recover after filtration DY lubricating oil vacuum oil filter function, cleanliness, moisture, gas content so, the acid value can be restored to the new oil standards, this time can be put into repeated use.

- Q: How does the vacuum oil filter protect the transformer?

- There are a variety of oil filter machine can protect effect on transformer, its main function is to maintain the dry transformer, and transformer oil in the water and gas pressure values and the values are in the acceptable range, as long as the indicators of transformer and transformer oil can be maintained normal, it plays a protective role.

- Q: What are the oil filters for? What are they used for?

- Improve the quality of lubricating oil, ensure the lubrication effect, reduce the frequency of lubricating oil, and increase the economic benefits.Generally used in large equipment industry, such as: compressors, steam turbines, etc.

- Q: What is an oil filter and what's the function?

- Oil filter is a complete non-standard machine, which is used in the fields of iron and steel, industry, machinery, power, energy, chemical, manufacturing, construction machinery, aviation and so on.

- Q: Is the temperature of the Kato vacuum pump casing working high and normal?

- Oil cooler is dirty, how to determine whether the cooler dirty, mainly to see the oil inlet temperature and the temperature difference between the oil inlet temperature, normal temperature difference between 20 - 30 degrees, if the external dust clogged radiators with compressed air blow static can, such as blowing off, you need to use the internal dirty radiator professional cleaning agent for cleaning; if you need to use an internal radiator blockage, water pump cleaning, cleaning time depending on the situation; such as water-cooled radiator is blocked, the best way is to cover with iron bars to clean the copper pipe before and after oil filter clogging apart; also can cause the screw type air compressor fault;

- Q: What kind of cooking oil filter is good?

- Pneumatic oil filter? Or the plate and frame oil filter? Now there's a filter called the blade

- Q: Has anyone filtered vegetable oil with a plate and oil filter?

- Secondly, you should be clear whether the filtered vegetable oil is edible or industrial vegetable oil, and if it is industrial vegetable oil, the manufacturer may not need sanitary permits, health and quarantine and other related supervision.

Send your message to us

Dental floss injection molding machine car windows on the sealing strip

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 g/m

- Supply Capability:

- 100 g/m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords