Decking Board Wpc Best Selling from Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

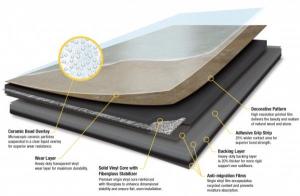

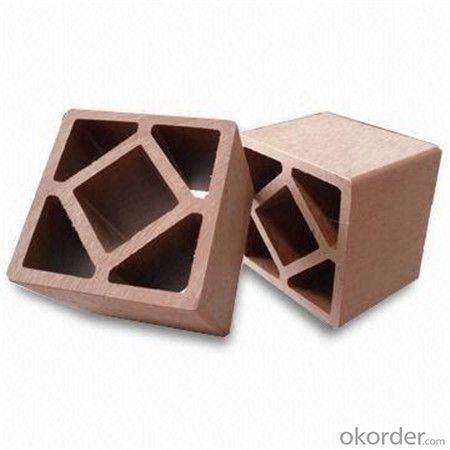

Structure of Decking Board Wpc

Item | Decking Board Wpc-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

Main Features of Decking Board Wpc

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

Picture show of Decking Board Wpc

Specification of Decking Board Wpc

Name | Decking Board Wpc |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

FAQ of Decking Board Wpc

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: There is a little water with plastic sheeting can pave the floor?

- Keep the ground dryThe floor needs to cement ground water in clean out before installation, otherwise it will produce a certain tidal wave, easily lead to the floor cracks, caused after the installation of the warped floor, so the floor before the cement ground moisture in row of clean, to ensure that the ground is dry.

- Q: PVC floor glue what glue plastic floor glue

- Plastic flooring is a broad term. There are a variety of views on the network, it should be said is not very accurate, plastic floor is a very popular in the world today, a new type of light ground decorative materials, also known as "light material".

- Q: To warm the original heat, the plastic floor above the surface of the floor to warm the heat emitted by the heat of the gas smell harmful to the human body?

- Adding appropriate additives, in the sheet of continuous base material by coating or rolling process, such as the production of floor roll. Plastic floor leather, although difficult to burn, self extinguishing, but at high temperatures, will decompose harmful gases, excessive inhalation, suffocating

- Q: The plastic floor gives off a plastic smell. Is it harmful?

- No, because no matter what plastic has its special taste, this plastic taste is not too much harm to the human body...

- Q: Plastic film on the floor for a long time with what method is easier to remove

- No matter what the film is on the ceramic tile and it is not the same material. I would like to use the principle of thermal expansion and contraction of the porcelain and film separation.

- Q: Plastic floor glue how shop, suitable for use at home

- Floor leather referred to as civilian leather, poor quality of materials, can be used for a year, if the furniture and the like in the above pressure will be broken.Different uses! Different life! Different quality! Different price!

- Q: What is the material of the plastic foam plate

- The general use of four roller mill factory plasticized PVC, after the pressure of the surface is smooth and smooth, cooling after the edge of the strip is the product

- Q: Home decoration with plastic floor, please? What are its strengths and weaknesses?

- Plastic floor has many advantages,:Elastic, comfortable, can give people a warm feeling; 2 surface in UV processing, pollution resistant, easy to clean; 3 green environmental protection, does not contain formaldehyde, inhibit the growth of bacteria; 4 case of water stains, good skid resistance,

- Q: Plastic floor, is expected to invest much capital investment

- From the major categories, new building materials products include refractories, lightweight building materials, waterproof building materials and insulation materials.

- Q: How to clean plastic floor

- 2, while the start of the water suction machine, while scrubbing the suction in addition to sewage, washing machine can not be washed to the plastic floor can be used to mop the dry cleaning detergent.

Send your message to us

Decking Board Wpc Best Selling from Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords