DC80-12AS Micro-computer Time Gravity Filling Machine Made In China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product Details

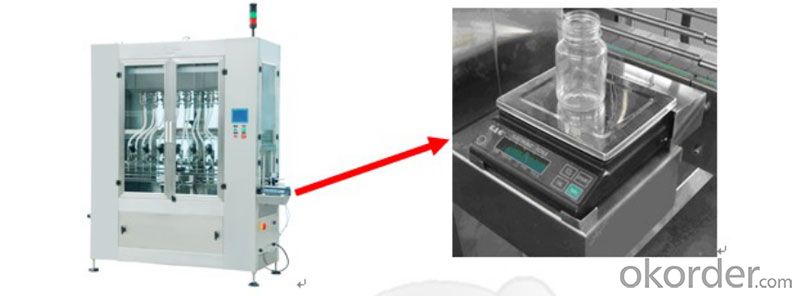

DC80-12AS Micro-computer Time Gravity Filling Machine is suitable for packing ES, SC material with good fluidity. It uses vertical structure with constant liquid level and time which realize the precise filling. It is controlled by the PLC, human interface and easy operation. The machine is equipped with electric scale weight feedback system which makes the volume adjust easier.

2、Features

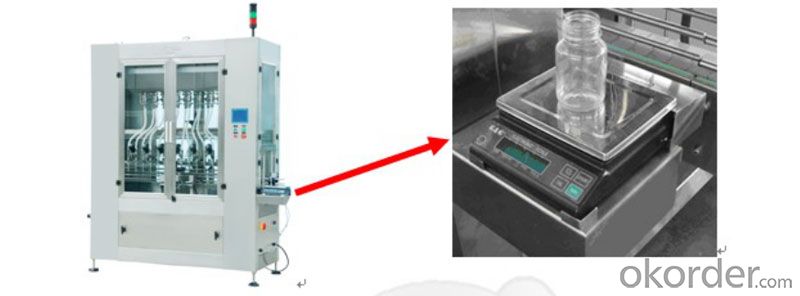

2.1 This machine is equipped with weight feedback system. When changing the bottle size or filling volume, only press one key in the touch screen can be adjusted. Electric scale can transfer the data into the system and fine-tune have to be adjusted in the touch screen by man. While the same series machine in the market has no same function.

2.2 The cylinder drives the diving of the filling nozzle and matched with the variable filling speed which can reduce foaming when filling which can avoid polluting the bottles.

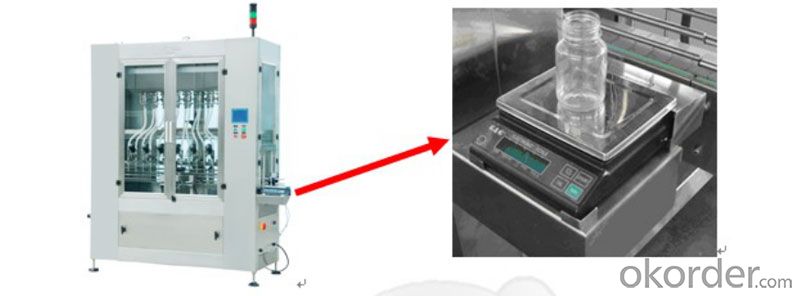

2.3 The latest designed bottle-chuck structure is adopted, convenient adjustment, and reliable structure.

2.4 Optimized Bottle-in and bottle-out control modes: Normal and fast. The fast mode has no delay in bottle-in and out which improves the capacity.

2.5 A disassembling filter is installed in the material feeding pipe to avoid the impurities influence the filling precision and lifetime of the valves.

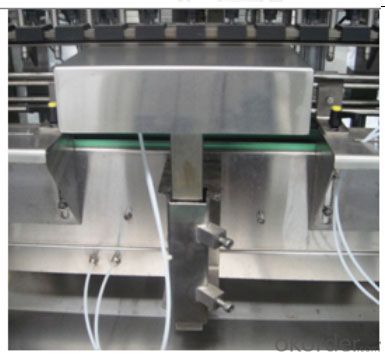

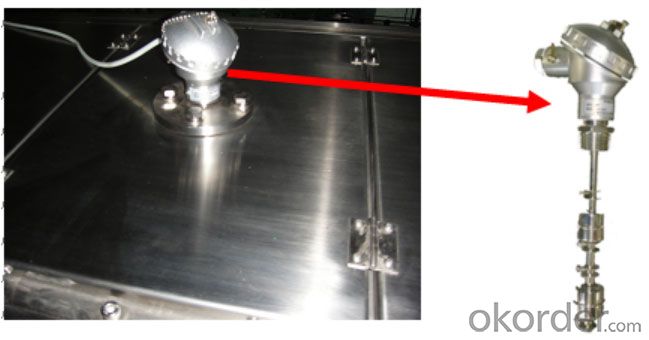

2.6 The material level sensor is used to check the level position under normal running of the machine,plus with high and low level check and alarm device. The level inspection device is made of PTFE, with perfect anti-corrosion feature.

2.7 A liquid holder which is controlled by an individual cylinder is installed under the filling nozzles. It can avoid the pollution to the bottle after the filling nozzles are OFF.

2.8 The whole machine use the frame of Stainless Steel 304 that with perfect anti-corrosion effect. The stainless steel cover and the toughened glass door prevent the dirty air during filling from polluting the environment. Meanwhile, dimensionΦ100mm exhaust outlet reserved on the top of the filling lancers which connected to the induced draught system for exhausting gas.

Notes: The connecting parts of pipe are all fast installed ,they enjoy convenient cleaning and maintenance.

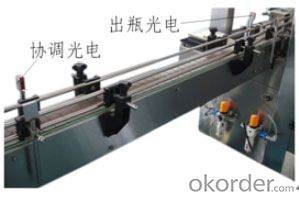

2.9 Filling Machine , equipped with the back coordination sensor, will automatically stop if the jam and topple of bottles. Or it will feed bottle again when the it operated normally.

2.10 Compared to the normal Angle seat valve that other suppliers using. We used German BURKERT Valve, which ensures the precision, durability and reliability of the filling volumes.

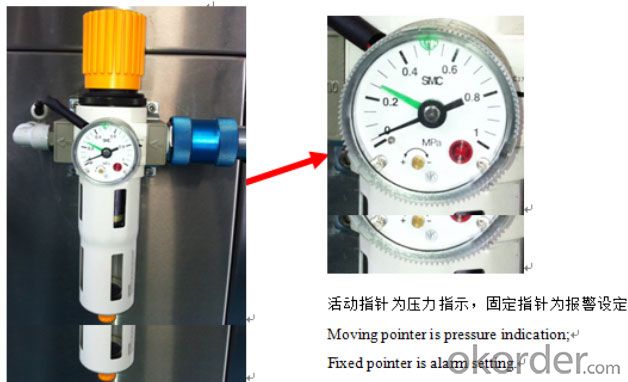

2.11 Japan Air pressure checking device used to checking the air pressure, when the air pressure is lower to the set number, the machine will alarm and stop automatically. This instrument is features for its convenient adjustment and durability.

3、Main Technology Parameter

1. Capacity: ≤ 6000 bottles/hr. (100ml water as medium)

2. Applicable bottle: Diamention Φ33-100mm,Height 80-230mm

3. Volumes: 40-1000ml

4. Precision: ±1%

5. Air pressure: 0.6~0.8 MPA

6. Power source: ~380V

7. Power: 1.0KW

8. External Diamention: 2000×710×2200mm (L×W×H)

9. Weight: about 480Kg

4、Images:

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: Paper bags, milk and plastic bags. What's the difference between milk and paper bags?

- The sterilization methods are different......Plastic bags of milk, that is, the use of bus sterilization, is the most do not destroy the milk in the nutrition of the way ~ is also very cheap, in general, buy that kind of milk to drink for a long time ~!The bag is Tetra Pak pillow packaging milk...... with the ultra high temperature sterilization, the sterilization ratio of bus destroys nutrients ~ and will make the lactose coking, to taste, to which + essence, in order to extend shelf life, go inside ~ + preservativeSo, I suggest that we buy plastic packaging milk, cheap and good ~!

- Q: What are the packing materials for heavy cargo transportation?

- The bulky goods need to use fixed bandages, tie belt, to prevent the occurrence of collision in the process of transportation, damage. Dragon Century Logistics has made big transport in Hongkong, and the handling and strengthening of large cargo before shipment are more mature.

- Q: Billycan what are the advantages compared with other packaging materials?

- The decoration is exquisite: the metal material has good printing performance; the design trademark is bright and beautiful; the packaging container made by it is noticeable, and it is a kind of good sale packing.

- Q: What are biodegradable packaging materials?

- Biodegradable packaging has a bright future and has attracted worldwide attention. In this paper, the properties, degradation mechanism, processing technology and application of various kinds of degradable packaging materials are reviewed. According to the mechanism of degradation, it can be divided into biodegradable plastics, biodegradable plastics, light / biological double degradable plastics and water degradation plastics.

- Q: What advantage does PET material have in packing?

- As a packaging material, PET has good mechanical properties, and its impact strength is 3~5 times of that of other films. It has good folding resistance

- Q: What material is the vacuum packing bag, please?

- Vacuum packaging is a general term for flexible packaging composite membrane products. If the temperature is different, there will be a lot of division: there is less than 100 bactericidal, and some need 100 degrees of sterilization, and 121 degrees and 135 degrees. Of course, there is also room temperature, the choice of this temperature under the condition of the sterilization method is irradiation sterilization. And also consider the content and weight of the package to determine the reasonable use of the packaging materials. There is no static, and the right is the best.

- Q: What are the commonly used packing materials?

- Other packaging materials / materials: Materials: gilding bronzing material laser film anodized aluminum foil paper bronzing film film foil stamping foil foil adhesive, coating adhesive adhesive composite rubber reinforcing agent: starch adhesive sealing rubber latex resin

- Q: What material or paper should I use for high-grade packaging?!

- Coated art paper or special paperMDF or industrial paperboardI provide the classic blue sky blue the Yanghe River Daqu wine with glue

- Q: What's the difference between a package and a package?

- Packaging refers to the packaging of products for the storage of various types of containers, such as barrels, boxes, bottles, jars, bags and other materials used for storage and custody of products.Packaging used in the manufacturing process as a component of a product and included in the cost of production at actual cost".

- Q: What can I do instead of the carton packing now?

- From the performance point of view, the permeability is good, waterproof and hardness is relatively poor, and can be disassembled, folded, easy to store. (if it is plated with plastic film box, waterproof and hardness will be improved, ventilation decreased)

Send your message to us

DC80-12AS Micro-computer Time Gravity Filling Machine Made In China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords