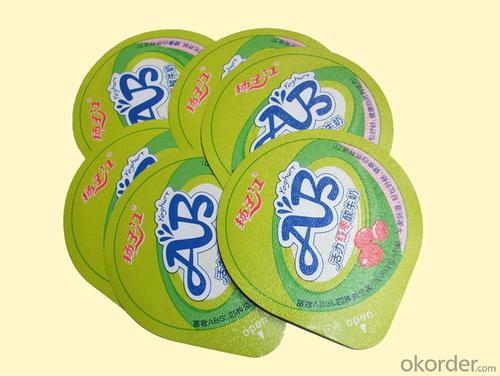

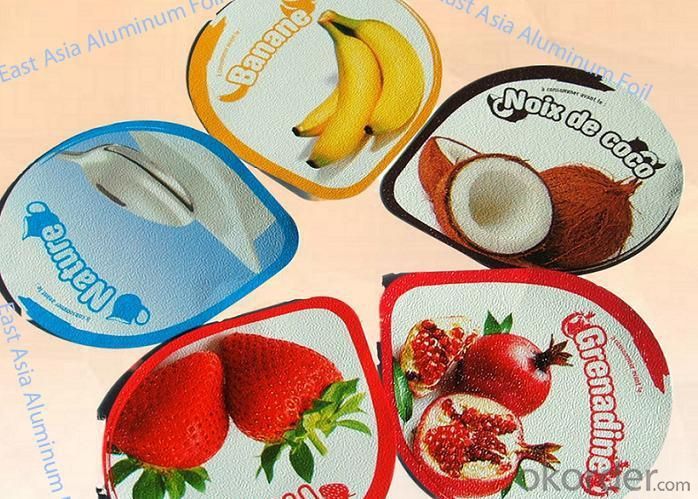

Aluminum Coated Lidding Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 15 Tons Per Day kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Multi-layer Coated lidding film:

Film structure: AL/coating

High barrier performance

Good high and low temp. resistance

Excellent sealing performance

Coated Aluminum foil or embossed

Thickness:20-200um

Width:30-300cm

Length:1500-3000m

Notice: Special products made as per customer requirements.

2. Usage of Multi-layer Coated lidding film:

Multi-layer Coated lidding film is widely used in dairy, processed food, medicine etc for lid sealing.

3. Packaging & Delivery of Multi-layer Coated lidding film:

One 20GP container can be loaded about 10-15tons.

By sea or by air all available.

- Q: What are the packing materials for heavy cargo transportation?

- Common transport packaging materials are: lining board, foam plastic, air cushion film, air cushion film, other fillers and so on.

- Q: What packing materials should be understood in purchasing?

- Other specific products, specific problems specific analysis, because the product form is not the same, liquid or chemical products packaging is not the same, the general small commodities, daily necessities of packaging almost the same

- Q: What's the difference between bulk food and prepackaged food?

- Is a small workshop to provide containers, that is, pre packaged food, is to take their own containers to buy, that is, bulk food

- Q: What are biodegradable packaging materials?

- Synthetic biodegradable packaging materials can be endowed with similar properties as traditional packaging materials, and the wide application of biodegradable packaging indicates its great potential to replace the current packaging materials.

- Q: What is accessory material? What is the difference between it and raw material?

- The auxiliary material is relative to the main material. The raw materials of various raw materials products mainly refers to the business entities and in the production process by the process to change its form or nature and main materials, auxiliary materials, fuel, repair spare parts, packaging materials, semi-finished products and other.

- Q: Cookies with tinplate packaging has what advantage

- Mature technology and high production efficiency: the production of tinplate has a long history, mature technology is a set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q: What material is the vacuum packing bag, please?

- Vacuum packaging material has two layers of composite, there are three layers of composite, common two layer composite more, want to see the products installed. Vacuum packaging material is divided into PET/PE PA/PE PA/CPP, PET composite can be evacuated, but relatively easy to leak, PET more brittle, PA/PE is a good vacuum performance, can withstand 100 degrees Celsius water sterilization, minus 30 degrees Celsius temperature freezing. PA/CPP is a vacuum cooking bag can withstand 120 degrees Celsius temperature cooking, minus 30 degrees Celsius temperature freezing. According to the customer installed products, the choice of material is not the same, can be customized according to customer requirements.

- Q: Does the desiccant belong to the packing material?

- Strictly speaking, the desiccant belongs to the auxiliary material of packing material, and belongs to the part of the packing material.

- Q: What are the commonly used packing materials?

- Metal packaging materials: tin foil hoop steel strapping buckle Blister aluminum PTP aluminum foil steel buckle ceramic glass material wood

- Q: What's the function of pearl cotton packing material?

- EPE pearl cotton foam material is a new kind of environmental protection packing and filling material. Its advantages are more and more recognized by people, so its use will continue to expand and innovate. Especially in the packaging and other industrial materials, it is better than the traditional wood performance, lower cost, higher grade, elegant appearance, better effect.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 450 Million |

| Main Markets | Mid East, Eastern Asia, Africa, Eastern Europe, Southeast Asia |

| Company Certifications | National Industrial Products Production License |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangdong |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 200-300 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 350,000 square meters |

| No. of Production Lines | Above 20 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

Aluminum Coated Lidding Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 15 Tons Per Day kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords