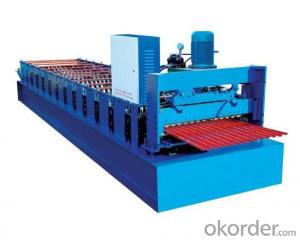

Cut-to-length Ridge Cap Roll Forming Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Zhejiang, China (Mainland)

Brand Name: ZHONGYUAN

Model Number: 315

After-sales Service Provided: Engineers available to service machinery overseas

Rollers material: No.45 Forged Steel with Hard Chrome

Cutter material: Cr12 mould steel with quench treatment

Cutting style: Automatic hydraulic cut to length

Shafts for rollers: Grand twice, ID72mm solid steel

Guarantee time: First year free, lifetime services

Cotrol system: Mitsubishi PLC & converter

Operation language: English or as per client`s

Quality system: ISO9001

Certificate: CE

Machine type: Cut-to-length Ridge Cap Roll Forming Machine

Packaging & Delivery

| Packaging Details: | 1. one 20ft container for loading one set machine with manual decoiler; 2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; 4. All Components Fixed by steel wire with Container. |

|---|---|

| Delivery Detail: | 50 days after receiving advance payment |

Why choose this Cut-to-length Ridge Cap Roll Forming Machine?

1. Designed by 15 years experienced R&D members with lifetime services.

2. Introduced Mitsubishi PLC with touch screen.

3. Need only one worker (minimum) to operate

4. Roller cover with 0.05mm chrome, ensure lifetime>10years

5. Cr12 mould steel cutter with quenched treatment. Blade with heat treatment.

6. Product cut-to-length.

7. 72mm diameter solid steel shaft

8. Certificate: ISO 9001, CE,

Main techncial parameters:

Motors power: total 7.7KW (depend on final design)

Material thickness:0.4-0.6mm

Effective width:385mm

Main application: Ridge Cap

Process flow:

Decoiler -- Feeding & Guiding -- Roll forming ---Hydraulic Cutting –product to run out table

- Q: What equipment, machine tools, lathes, or other equipment? Probably are a length of not more than 30cm a number of hollow

- linoleum, tubing and oil separator, etc. should be complete and well installed. According to the lubrication instructions

- Q: What is the difference between turning and milling machine and other machine tools?

- Now the world famous milling and milling manufacturers are: WFL, DMG, MAZAK, Mori Seiki, Germany Hammer and China Shenyang Machine Tool Plant, Yangzhou special machine, etc.

- Q: What is the meaning of CNC machining?

- Decoding, so that the machine to implement the provisions of a good action, through the cutting of the blank material into semi-finished finished parts.

- Q: What is the meaning of R in the data lathe?

- CNC lathe: the digital program control lathe short, set universal lathe, high precision machining precision lathe and high processing efficiency of the special type of lathe in one, is the largest domestic use, the most extensive coverage of a CNC machine

- Q: What are the metal cutting machine tools?

- Their forms are diverse, but they have many common phenomena and laws, and these phenomena and laws are the common ground for learning a variety of cutting methods.

- Q: Why is the CNC lathe so precise, what is it?

- In summary, so CNC lathes compared with the traditional lathe, the machining accuracy has been greatly improved.

- Q: Machine operating procedures

- The operator must pass the exam and hold the "equipment operation card" of the machine to operate the machine.

- Q: Compared with ordinary machine tools, how to look at the inevitable emergence of CNC machine tools

- Third, the surface requirements for some complex surface, with ordinary machine is difficult or can not be processed at all, must use CNC machine tools to find through the bit to achieve.

- Q: What is the advantage of other CNC machine tools compared to other equipment?

- High precision machining, high production efficiency,

- Q: What is the characteristic of Taiwan's Cheong Hong machine compared to other machine tools? Compared to Shenyang Machine Tool, Gao Feng machine, Friends of Ka?

- Taiwan's Che-hung is better than they are.

Send your message to us

Cut-to-length Ridge Cap Roll Forming Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords