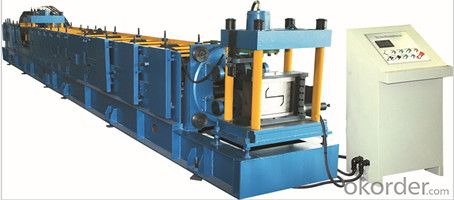

Ridge Cap Cold Roll Forming Machine for Glazed Tile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ridge Cap Roll forming machine for Glazed Tile

Technical data of ridge cap roll forming machine

Suitable Material | Q235 color steel sheet;0.4-0.6mm | |

Working speed | About 3.0m/min | |

Step distanc | adjustable according to requirement (>=250mm) | |

Power Requirement | Main motor power: 5.5 Kw(Depend on final design) | |

Hydraulic station power: 5.5Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 | |

Material of shaft | High quality 45# steel, Dia. is 72mm. | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 10500KGS | |

Size of machine installation | About 18m×1.8m× 1.5m (Depend on final design) | |

Our ridge cap Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines |

- Q: What is the instrument lathe, how to use it?

- The instrument lathe adopts spring chuck fast clamping, the motor directly drives the spindle, the size of the disc fast hand-operated operation, the vertical and horizontal positioning control turning, part of the instrument lathe is equipped with flange, tailstock device, mold clamping machine,

- Q: What equipment, machine tools, lathes, or other equipment? Probably are a length of not more than 30cm a number of hollow

- check the lubrication system oil storage parts of the oil should meet the requirements, closed well. Oil standard, oil window, oil cup, grease nozzle, oil

- Q: What is the meaning of R in the data lathe?

- U: the amount of feed (exit) required to exit or insert the original Y-axis coordinate point;

- Q: How about CNC machine tools

- CNC machine tools are now the most commonly used machine tools, depending on the type

- Q: What is the difference between CNC machine tools and general machine tools?

- 1, the use of a fully enclosed or semi-enclosed protective device CNC lathe with a closed protective device to prevent chip or cutting fluid flying out, to the operator to bring accidental injury.

- Q: Lathe C6140 meaning

- And ordinary lathe, 7 said multi-knife and profiled lathe, 8 said wheel, shaft, ingot, roller and shovel lathe, 9 said other lathe.

- Q: What is the main work of CNC machine tools?

- CNC machine tools are the main equipment of mechanical processing, compared with ordinary machine tools is a high-performance automated machine tools, with the following obvious features:

- Q: Which machine is the leading machine

- 000837 Qinchuan development, gear grinding the world's first, and there are military restructuring expected.

- Q: The processing range of the lathe

- Usually in the metal cutting machine occupies the largest proportion, accounting for about 30% of the total number of machine tools.

- Q: What tools (machines) are required for lathe processing?

- CNC lathe processing is usually controlled by the control system, servo system, detection system, mechanical transmission system and other auxiliary systems.

Send your message to us

Ridge Cap Cold Roll Forming Machine for Glazed Tile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches