Cryogenic Insulation Paper with Aluminum Foil (One Layer)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fire retardation glass fiber Cryogenic & Insulation paper is made of superfine glass fiber with special processing. This is usually used with aluminium foil and used for transport containers which store liquid helium, liquid hydrogen, liquid nitrogen,LNG etc.

The superfine glass fiber Cryogenic & Insulation paper's diameter between 0.1-0.6μm and fiber glass filament (diameter between 3-5 μm). According to a certain proportion, the paper is produced under the wet & vacuum forming process to make the paper have the space lattice structure. All the glass fiber is inorganic material, so it has outstanding flame retardant properties. Specifically engineered for use at big temperature range (approaching -273℃—500℃) and also the paper is really stable in the low temperature condition.

It shares the advantage of low thermal conductivity but high thermal contact resistance, fast out gassing rate but low gas emission under vacuum conditions and wide applicable working temperature range (269C~500C). It is the top selected insulation materials applicable for cryogenic liquid storage & mobile containers and pipeline systems for liquid oxygen, nitrogen, hydrogen, helium, argon, LNG and etc.

Cryogenic Insulation Paper Features:

The main way of heat conduction is by radiation heat exchange in the low and vacuum condition. In order to reduce the radiation heat exchange to meet the good heat insulation effect, by using aluminum foil for reflecting screen and superfine glass fiber insulation paper for spacer, then the multilayer combination of aluminum foil reflective screen and cryogenic & insulation material can build up the efficient thermal barrier against heat transfer in insulated vacuum storage containers.

Cryogenic Insulation Paper Application:

Cryogenic liquid (liquid helium, liquid hydrogen, LNG, liquid oxygen, liquid nitrogen, liquid argon, etc.)

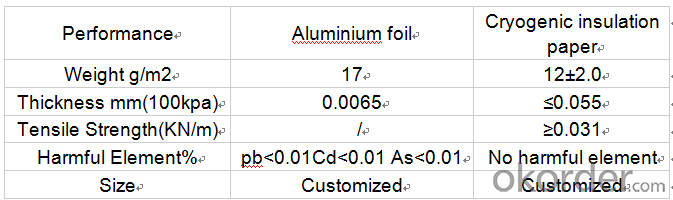

Cryogenic Insulation Paper Specifications

1.light weight

2.good uniformity

3.low thermal conductivity

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: I would like to ask how the process of cryogenic treatment

- Biology: fast cooling, can prevent the crystallization of cells in the water, does not destroy the cell organization. In the preservation of sperm, organ preservation, food preservation, preservation of certain life and so onMedical treatment: cryotherapy, treatment of certain skin diseasesSpace: the space environment simulation, satellite ground test station, using liquid helium, create -200 degrees of low temperature.Noise: high sensitivity radar telescope, using liquid helium cooling, receiving device, noise reductionVacuum: the use of cold well technology can get high vacuum

- Q: Can the cryogenic phase control the cooling rate?

- If it is just a simple container or box, it is difficult to control the temperature. The program can control the temperature of cryogenic equipment, can also control the cooling rate

- Q: How many changes in the properties of the cryogenic metal?

- The name of the processing content specification / processing content of the original service life (sub / piece) after the service life (times / pieces)1 milling cutter milling keyway 7.5-2NT 40034352 step drilling hole Phi: 1.2, 23, 1331004163 milling cutter milling air hole Phi 11.5, 32-2NT

- Q: Cryogenic treatment to improve what performance?

- To improve the hardness and strength of the workpiece;Ensure the dimensional accuracy of the workpiece;Improve the wear resistance of the workpiece;

- Q: Ultra low pressure casting mold useful, how to arrange the process? Thank you

- Cryogenic treatment in the connector industry and plastic mold industry has a large number of applications, connectors and plastic products industry production temperature is not high, about 300 degrees! Thus the mold in the production of hot and cold alternating stress is less, after doing a cryogenic treatment, the role of the stability of the size of the more obvious, tube time is longer!

- Q: What is the meaning of vacuum cooling in heat treatment

- Placed for a period of time, known as cryogenic treatment, under normal circumstances are usually treated with liquid nitrogen.

- Q: What is a cryogenic fast line

- Cryogenic metal industry technology refers to the black metals, nonferrous metals, polymers, carbide and so on at cryogenic temperature heat preservation material, make it happen at room temperature and never happened in the process of heat treatment of the internal structure change, lead to the change of macro performance. For example: die steel, high speed steel, cemented carbide strength and toughness were improved after cryogenic treatment, and break through the traditional hardness and toughness of contradictory phenomenon, show the comprehensive performance improved. Domestic contribution to cryogenic technology research institute of Chinese academy of sciences, is the biggest should from the several aspects, such as equipment, mechanism, process research and extension of cryogenic technology, cryogenic in cutting tools, moulds, valves, and other industries extensively with the Chinese academy of sciences of physics and chemistry ? all the inseparable relations

- Q: What is the meaning of cryogenic technology in the mechanical process, what is the specific practice?

- High speed steel W18Cr4V cryogenic hardness, impact toughness and wear resistance are significantly improved with the use of its manufacturing tool life increased by 2~5 times

- Q: What is the meaning of deep frozen

- So people use frozen ways to preserve food. Generally in a very short period of time, such as half an hour, so that the need to freeze the food quickly reach the specified ultra-low temperature, such as -30 ~-40 C.

Send your message to us

Cryogenic Insulation Paper with Aluminum Foil (One Layer)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords