CPG-6F Automatic In-line Capping machine Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product Details

JCP-6A In-line Structure Capping Machine is making up with cap sorter, cap falling rail, bottle-tightening structure and capping wheels. By the tightening of the belts, the bottles finish the movement of cap scratch, push and capping. It applies to the capping of round and flat bottles. This capping machine is with easy structure and adjustment. When changing the bottle type, you do not need to change the spare part, only adjustment is enough.

2、Features

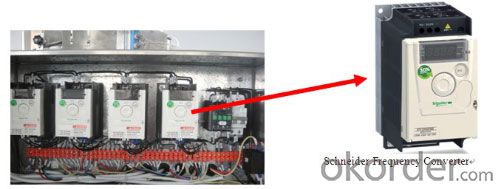

2.1 The whole machine uses Schneider brand which can make sure the stability of the machine.

2.2 A cap sensor is installed in the cap hopper. When there is not enough cap, the elevator will start working to make sure providing caps.

JPACKS Centrifugal Cap Sorting Bowl is also a great solution for high speed sorting and noise reduction for both flat, non-flat and specialty caps.

Specifications:

Custom tooling available

Optional diameters to accommodate varying cap sizes and types

2.3 Use a handle to adjust the height and tight of the machine,stable and reliable.

2.4 A mirror is installed to check the state of caps.

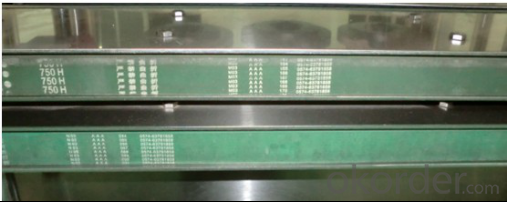

2.5 The tightening belt can last for a very long time.

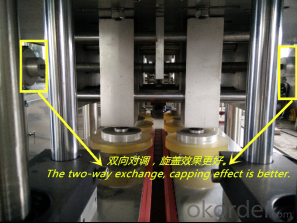

2.6 The capping wheels with new material can last for a very long time.

2.7 Intectual blow back lid system

Intectual checking back lid, high-speed magnetic valve rejector, solving the noise polluction, large comsumption of air and low qualified rate. Convenient adjustment.

3、Main Technology Parameter

3.1 Capacity:≤8000 Bottles/hour

3.2 Applicable Bottle Diameter:Φ35-96mm Bottle height: 80-230mm

3.3 Cap Specification:Φ12-50mm Cap height: 15-40mm

3.4 Air Pressure:0.5~0.7 MPA

3.5 Power Source:~220V、50HZ

3.6 Power:2KW

3.7 Weight:about 650Kg

3.8 External Dimension:2000×950×2100mm(L×W×H)

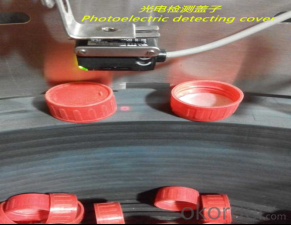

4、Images

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: What are the characteristics of paper holders in comparison with other packaging materials?

- At present, the use of foam product packaging can be roughly lined with paper tray exchange.x0d followed by the paper tray and the production cost is low, craft paper holder than styrofoam simple fast, short cycle time and production cost, and the cost of raw materials is low. It can not happen, not afraid of electrostatic erosion and prevent vibration, the function is better than that of styrofoam in many ways, are better than other materials.

- Q: What are the main categories and applications of packaging materials?

- Paper packing materials: wrapping paper, honeycomb paper, paper bag paper, desiccant packing paper, honeycomb paperboard, kraft paper, industrial paperboard, honeycomb paper core;Plastic packing material: PP packing belt, PET packing belt, tearing film, winding film, sealing tape, heat shrinkable film, plastic film and hollow board;Composite flexible packaging materials: flexible packaging, aluminum plated film, iron core wire, aluminum foil composite film, vacuum aluminized paper, composite film, composite paper, BOPP;Metal packaging materials: tin foil, strip, hoop, packing buckle, Blister aluminum, aluminum foil, aluminum plate, steel buckle PTP;Ceramic packaging materials: ceramic bottles, ceramic cylinders, ceramic altar, ceramic pot;Glass packing material: glass bottle, glass jar, glass box;Wood packing materials: wood products and man-made wood boards (such as plywood, fiberboard) made of packaging, such as wooden cases, wooden barrels, wooden boxes, wood plywood, fibreboard boxes, plywood boxes and wooden pallets;

- Q: Which industry does the packing product belong to?

- Packaging products are defined as: "in the process of circulation of goods to protect products, facilitate storage and transportation, and promote sales, according to certain technical methods adopted containers, materials and auxiliaries, such as the overall name.". Also refers to in order to achieve these purposes and use containers, materials and auxiliary in the process of exerting certain technical methods and other operations.

- Q: Cookies with tinplate packaging has what advantage

- Mature technology and high production efficiency: the production of tinplate has a long history, mature technology is a set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q: What plastic packaged food is safer?

- PP plastic food packaging materials, PP special soft, good toughness, non-toxic, high temperature resistant, often make catering appliance or other high-temperature packaging products, our hotel is packed with PP material boxes.

- Q: How many kinds of packing are there?

- According to packaging products, materials are: paper products packaging, plastic packaging, metal packaging, bamboo and wooden packaging, glass container packaging and composite materials packaging;

- Q: Does the desiccant belong to the packing material?

- Many used desiccant is involved in metal industry, some equipment and parts in the transport process, to prevent corrosion, reduce the humidity inside the packaging, the possibility of reducing dew temperature, the general formula is the packaging materials used.

- Q: What's the difference between a package and a package?

- Packaging refers to the packaging of products for the storage of various types of containers, such as barrels, boxes, bottles, jars, bags and other materials used for storage and custody of products.Packaging used in the manufacturing process as a component of a product and included in the cost of production at actual cost".

- Q: Is the antistatic value of PS material (or other packing material) as small as possible?

- PS materials need special antistatic agent, Wuxi giant plasticized material has an antistatic agent, good, can be used in ABS, GPPS, HIPS, PPS, EPS and so on, the effect is good.

- Q: What's the function of pearl cotton packing material?

- Pearl cotton packing material has many advantages, such as waterproof, moisture-proof, shockproof, sound insulation, thermal insulation, good plasticity, toughness, recycling, environmental protection, strong impact resistance, and so on. It also has good chemical resistance. Is the ideal substitute of traditional packaging materials.

Send your message to us

CPG-6F Automatic In-line Capping machine Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords