Corundum Brick Ceramic Tiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

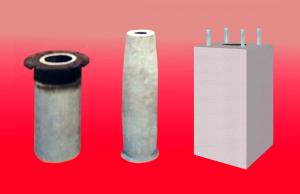

What is Corundum Brick?

l Corundum Bricks are high alumina refractory bricks are made for extreme demands. The alumina content in Corundum Bricks can be traced to the use of synthetic corundum of high purity, such as white fused alumina or tabular alumina. Additional ingredients are special refractory clays, reactive alumina and very pure modifications of silica.

What are the applications of Corundum Brick?

Corundum Bricks can be used nearly all fields of industrial application where extreme high temperature and increased resistance against aggressive slags and atmospheres. Such properties or features of Corundum Bricks are necessary especially in the chemical industry and for the production of carbon black. The addition of chromium oxide, zirconium oxide and phosphates lends the bricks excellent structural flexibility, which is required for ash melting furnaces and gas reactors in incinerators.

Image of Corundum Brick

Technical Data of Corundum Brick

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What material is used in an iron smelting furnace?

- In fact, refractory refractory ah is special ceramic frequently used AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials.

- Q: What are the advantages of refractories?

- Special refractories are new inorganic non-metallic materials developed on the basis of traditional ceramics and refractory materials. For example, AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Often used insulation refractories are diatomite products, asbestos products, insulation panels and so on

- Q: What equipment is used for producing diamond blanks? How much is the investment?

- You'll have to invest about about one million if you want an electric furnace. A power distribution room is easiest to approach one hundred thousand. Electric furnaces, power distribution cabinets and transformers must be around one hundred and ten thousand.

- Q: How to improve the induction furnace campaign, from the promotion of refractory life start

- According to the use of atmosphere, choose the appropriate spraying materials, such as infrared radiation paint

- Q: What refractory materials are used in industrial furnaces?

- Economically, it is necessary to do technical and economic analysis when selecting materials reasonably. Under the premise that the technical indexes agree with the working conditions of the furnace, the refractory materials with low quoted price should be used as much as possible, without high-grade finished products. To think about whether to make self (such as irrigation, refractory concrete) as far as possible to repair old.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: How do corundum bricks bind?

- High temperature bonding clay can be used for bonding masonry

- Q: What kind of refractory material will be used in the glass kiln?

- It has the best resistance to high temperature E glass corrosion, its erosion basically does not cause pollution to the glass liquid, so it has become the first choice of E glass unit refractory bricks.Dense chromium oxide is formed by isostatic pressing. Its density is very high. The main technical indexes include Cr2O3 content >94%, porosity <15%, volume density >4.24g/cm3, and erosion loss only 1/10 of compact zirconia brick. Used in the E glass furnace unit kiln, directly contact high temperature molten glass melt, wall, melting parts, high temperature parts, pool bottom, main channel, pool wall and pool bottom, transition channel, pool wall, etc..

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: What are the refractory materials?

- Not a good answer. You can sort out, such as: neutral, alkaline, acid refractory. Different kinds, of course, raw materials are different.For example: MgO-C brick basic refractories: magnesia (fused, high purity graphite) + + + phenolic resin additives (silica fume or aluminum or silicon carbide or high temperature asphalt) etc..

Send your message to us

Corundum Brick Ceramic Tiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords