Corundum Brick - High Purity Corundum Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Purity Corundum Refractory Bricks

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | High Purity Corundum |

| SiO2 Content (%): | 0.2% | Al2O3 Content (%): | 99% | MgO Content (%): | -- |

| CaO Content (%): | -- | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | -- |

| SiC Content (%): | -- | Model Number: | CB | Brand Name: | |

| Name: | High Purity Corundum refractory bricks | Company: | Sinosteel Luoyang Institute of Refractories Research Co., Ltd. | Experience: | 51 years |

| Type: | R&D- Production-Sales/Manufacture | Certification: | ISO,CNAB,IAF | Main markets: | India,South Korea,Denmark, Russia, Europe, the United States |

| Packaging: | Fumigated pallet 2 Four bricks in carton, separated by foam board | Model: | CMB-70,CMB-80,CMB-90,CB-99 | CCS,MPa: | 70 |

| Long term service temp.,℃: | 1700 |

Packaging & Delivery

| Packaging Details: | 1 Fumigated pallet 2 A stable stack of bricks 3 Lables on two opposite faces 4 Card edges 5 Steel or nylon bands 6 Plastic wrap 7 Overall dimension:1.0*1.0*1.0m (Routine) 8 Gross weight:1.2-1.6MT (Routine) |

| Delivery Detail: | Based on order |

Specifications

Corundum series with high density, good mechanical property, stable chemical property, maily used in chemical, ceramic industry.

Product Description

1. High purity corundum bricks, which is characterized by good mechanical property at high temperature and good chemical stability,

2. Is widely used in oil gas gasifier, ethylene-generated furnace, and ammonia decomposing furnace in petrochemical industry, carbon black reactor in chemical industry, and high temperature kilns in refractories and ceramics industry.

3. It has gained the Third Prize of Science & Technology Progress from Sinopec and the former Ministry of Metallurgy Industry.

4. The brick has been used in the thermal equipment of domestric made or imported. It has been exported and used in German Texaco gasifier with good performance.

Physical and chemical index

| Item | Corundum Mullite Products | Corundum product | |||

| CMB-70 | CMB-80 | CMB-90 | CB-99 | ||

| Bulk density,g/cm3 | 2.5 | 2.6 | 2.8 | 3.15 | |

| Apparent porosity,% | 19 | 19 | 19 | 18 | |

| CCS,MPa | 60 | 70 | 70 | 70 | |

| Refractoriness under load,℃(0.2MPa,0.6%) | -- | -- | 1700 | 1700 | |

| Long term service temp.,℃ | -- | -- | 1700 | 1800 | |

| Linear change on heating,(1600℃×3h) | -- | -- | ±0.3 | ±0.3 | |

| Chemical composition,% | Al2O3 | 68 | 78 | 88 | 99 |

| SiO2 | -- | -- | -- | 0.2 | |

| Fe2O3 | 0.4 | 0.3 | 0.3 | 0.15 | |

Our Services

♥ Research of application basis, new technical process and new technology, development of new product, and technical consultation.

♥ Optimum solution and product supply of refractories for high temperature industries, such as iron&steel, non-ferrous, petrochemical and building materials.

♥ Engineering design, contract and consult for refractories, and civil architecture design.

♥ Research,development, manufacture and sale of superhard materials.

♥ R&D, manufacture and sale of special packing materials for export.

♥ Inspection,supervision and arbitration of refractories.

♥ Consultation and services in refractories information.

♥ Training and cultivation of high-level talents in refractories profession.

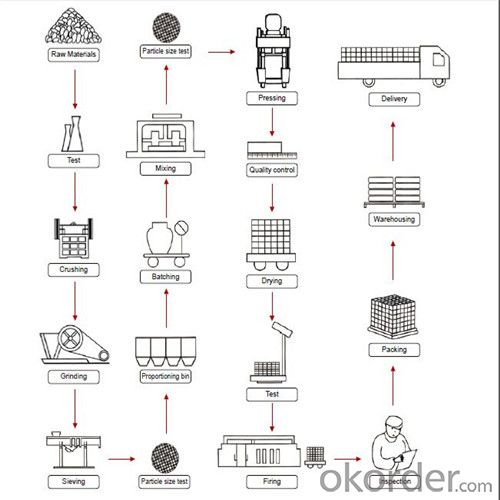

1.Strong professional:

Our compay has many year producing experiece in refractory product.Our manager supervise on a various refractory's production materials,process control,quality supervision and package delivery,and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system certification.And the annual supply of shaped and unshaped refractory product is 3000-5000tons per month.

3.Annual exports:

Now we have gained a global sales network reaching Russia,Mongolia,South Korea,Vietnam,Pakistan,Bulgaria,Finland,Greece,Spain,Congo,Angola,South Africa,and Maldives,Jordan,United Kingdon,United States and so on.

4.Production equipment:

Production and testing equipments are new,complete and automated or semi-automated.Such modern facilities and equipment have proviede the fine technical guarantee for the production and testing.

5.Testing equipment:

Our company's testing equipmets as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

6.Our competitive Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients’ quality requirement.

6.Safty packing,prompt delivery time,and excellent after-sales services.

7.Large stocks. Guarantee prompt delivery.

8.Professional Packing. Avoid damage and secure the goods in transportation

Warmly welcome friends and customers all over the world to pay a visit to factory!Hopefully both of us can establish a long-term cooperation!

FAQ

3.Common question:

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What is the whole process of doing business with us?

A:1.First,please provide details of the products you need we quote for you.

2.If price is acceptable,we provide Proforma Invoice.If need the sample to do a test,we will send a sample to PI to you for doing the payment.

3.If client approve sample and require for sample production for order,we will provide Proforma Invoice for client.and we will arrange to produce at once when we get 30% deposit.

4.We will send photos of all goods,packing,details after goods are finished.After be confirmed by clients,Pls transfer the balance 7.% for the order.We will arrange shipment and send all orginal docs to you.

Q4: What advantages we have?

A: 1.Rich experience:We have more than 10 years experience in this industry.That means,we can preview the problems for the orders and products. Therefore,it will make sure to reduce the risk of bad situation to happen.

2.Best technique:We have a strong technique team so that can explain the usage process and settle technique problem for production.If you need,we can visit your company to offer the technique support for your produce line.

3.Offer all line service:For the new manufacture,we can offer professional guidance and offer complete set material to you for your products which you need to make.

4.Point to point service:There is one sale who will serve you from inquiry to products shipped out.During the process,you just need to discuss with her for all problems and the way saves much time.

5.Free design:for the mold,If you are not ready for the designs,the professional designers will be able to help you with it freely, you just offer size is ok.

6.Strict QC:For each order,strict inspection will be carried out by the QC department before shipping. The bad quality will be avoid within door.

7.Shipping:We have shipping department and forwarder,so we can promise faster delivery and make the goods well protected.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- Fused zirconia corundum brick is pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is eutectoid zirconium corundum and plagioclase phase, glass phase filling between their crystallization.

- Q: What is the price of concrete self insulation bricks?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: How to improve the induction furnace campaign, from the promotion of refractory life start

- Select suitable insulation materials, such as polycrystalline facing blocks and ceramic fiber modules, depending on the service temperature

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- The sinter plate dust collector is also called plastic plate dust collector. The utility model has the advantages that the utility model can adapt to various complicated working conditions, the dust removal rate is 99.99%, the utility model has the advantages of long service life, stable operation, high temperature resistance, and the utility model is a leading dedusting equipment in china.

- Q: What is the difference between corundum and high alumina?

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Two aluminum liquid hydrogen phosphate using spray paint, cement, refractory castable and binder for foundry industry, mainly used in refractory industry corundum, chromium corundum nozzle coal water slurry gasifier with chromium aluminum zirconium corundum brick production.

- Q: How do corundum bricks bind?

- High temperature bonding clay can be used for bonding masonry

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- The expansion curves of fused cast AZS brick at 1000 DEG C near a crystal anomaly, its internal changes of ZrO2 crystal are reversible, with large volume change, therefore, products containing ZrO2, should not be used in the temperature of 1000 DEG C, often have sharp fluctuations in the position. When baking the kiln, the temperature can not be too large at 900~1150 degrees centigrade. Generally, the temperature can not exceed 15 degrees /h, and the temperature should be raised steadily. Some parts to prevent the cold, with other brick protection, to prevent explosion.

- Q: What can zirconium sponge do for those industries?

- Uses: aerospace, military, nuclear reactions, atomic energy, and metal superhard materials, the manufacture of bulletproof alloy steel, can also be used in the reactor uranium fuel coating alloy; zirconium at high temperatures easy to launch electronicProduct characteristics: zirconium metal has very strong corrosion resistance, ultra high hardness and strength

Send your message to us

Corundum Brick - High Purity Corundum Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords