Construction Hoist Building Machinery Lifter

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction Hoist Description

Feature: Construction Hoist Condition: New Application: Construction

Payload(kg):3000 Lifting Speed(m/min):33 Motor Power(kw): 3*15

Safety Device: SAJ50-1.2 Cage: Single Counterweight: No

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SC300

Packaging & Delivery of Construction Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Construction Hoist

● The gearing adopts imported bearing, enameled cable, and oil seal.

● The electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG.

● The racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts.

● The steel structure uses quality steel from famous domestic manufactures.

● The surface of the structure can apply paint-spray, parkerozing baking finish or hot galvanizing processing according

to users requirements,

● The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminm board.

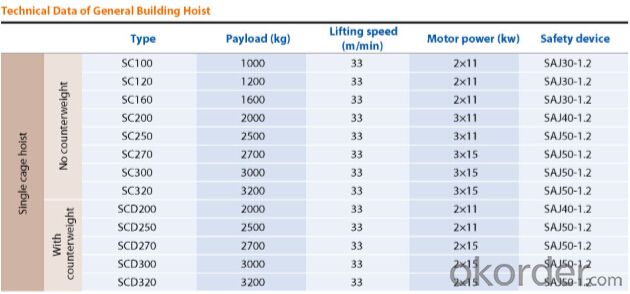

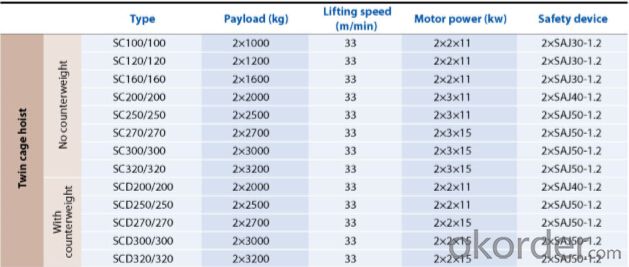

Construction Hoist Specifiction

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: The construction elevator is commonly used in the process of the project

- For example, building construction is used for more than two floors

- Q: Is it possible to utilize a building hoist for the purposes of renovation projects?

- <p>Yes, a building hoist can be used for renovation work. These hoists are designed to lift and lower materials and personnel efficiently, making them ideal for construction and renovation projects. They help in moving heavy materials such as bricks, cement, and tools to different floors without the need for manual labor, thus increasing safety and productivity. However, it's crucial to ensure that the hoist is properly installed, maintained, and operated by trained personnel to avoid accidents and ensure the safety of all involved.</p>

- Q: What factors should be considered when selecting an appropriate building hoist for a specific construction project?

- <p>Choosing a suitable building hoist involves assessing several factors: the weight capacity required, the frequency of use, the height and number of floors in the building, the size and shape of materials to be lifted, and safety features. Consider the hoist's speed and efficiency, as well as its ease of installation and maintenance. Consult with hoist manufacturers or experts to ensure the hoist meets local safety regulations and fits the project's specific needs. Always prioritize safety, reliability, and compatibility with the construction workflow.</p>

- Q: Gear rack driven

- The driver of the elevator ladder cage is driven by two or three worm gear reducers, which carry heavy lifting parts, and gravity is carried by the rack. At rest, the force point is in the meshing of the gear and rack. It is the main balance between the rewire rope and the ladder cage and the relative motion. For heavy can improve dynamic performance, a heavy on the ladder cage running more smoothly, when a fall, fall of heavy can slow down the ladder cage speed, it should be said that safety performance is better.

- Q: Is it safe to use an electric lifting device indoors if it is not certified for indoor use?

- <p>It is not advisable to use an electric lifting device indoors if it is not certified for such use. Non-certified devices may not meet safety standards for indoor environments, including electrical safety, structural integrity, and risk of fire. Using uncertified equipment can lead to accidents, injuries, or property damage. Always ensure that any lifting equipment complies with local regulations and is suitable for the intended environment to maintain safety.</p>

- Q: Is it possible to utilize a building hoist for construction or renovation purposes?

- <p>Yes, a building hoist is commonly used for construction and renovation work. It is designed to lift materials and workers vertically, making it an essential tool for multi-story construction projects. Hoists facilitate the movement of heavy materials like cement, bricks, and steel, as well as personnel, enhancing efficiency and safety on the construction site. They are particularly useful in scenarios where cranes are impractical or unavailable, making them a vital component in the construction and renovation process.</p>

- Q: The construction elevator should have those procedures

- Installation and demolition plan, content can guide safe construction, and have complete approval procedure. The installation and demolition of the team must hold the certificate of safety of the above provincial competent authorities. There should be substantial content for the safety of the installation, the demolition of the staff and the safety technology of the driver. Should have basic design, hidden acceptance and concrete strength speech. The inspection and acceptance of the installation completed and the inspection presentation of the competent part. The construction elevator has a record. The elevator is using a copy of the original copy. An employee's special course post certificate. Other relevant safety information. The construction elevator is a larger vertical transport equipment, and the safety and blood lessons of previous accidents are profound. Strict inspection, the key prevention of elevator accidents, is the key link of the safety management at the construction site, and the safety management staff at all levels should be awake and familiar.

- Q: Is it feasible to utilize a building hoist for lifting heavy objects when the ground is not level?

- <p>A building hoist is generally designed for vertical lifting in a stable and level environment. Using it on uneven ground can be hazardous and is not recommended due to the risk of tipping or instability. For lifting heavy objects on uneven ground, it's advisable to use specialized equipment like mobile cranes or all-terrain forklifts that are designed to handle such conditions. Always consult the manufacturer's guidelines and safety regulations before using any lifting equipment.</p>

- Q: This question asks about the safety mechanisms or features that are included in a hydraulic building hoist to ensure its secure operation.

- <p>Hydraulic building hoists are equipped with several safety features to ensure secure operation. These include overload protection to prevent the hoist from lifting more weight than it is designed for, emergency stop buttons for immediate cessation of operations, safety hooks or shackles to secure the load, and lower limit switches to prevent over-lowering. Additionally, they often have a fail-safe valve system that locks the hoist in place if pressure is lost, and a cage or gate to protect operators from falling objects. Regular maintenance and inspection are also crucial for maintaining the safety of these hoists.</p>

- Q: How many meters is the wall of the construction elevator?

- I know the bunter lift is six meters so you can get it

Send your message to us

Construction Hoist Building Machinery Lifter

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords