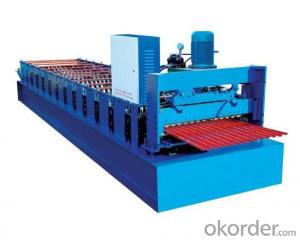

construction curving eave Roof Panel Forming Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Components

1.Manual Decoiler: one set

Un-powered,Manually control steel coil inner bore shrinkage and stop,

Max Feeding width: 1250mm,coil ID range 508mm±30mm

Capacity: Max. 5 Ton

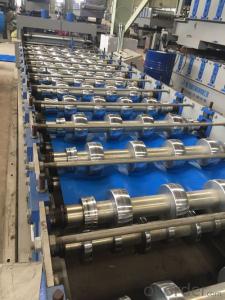

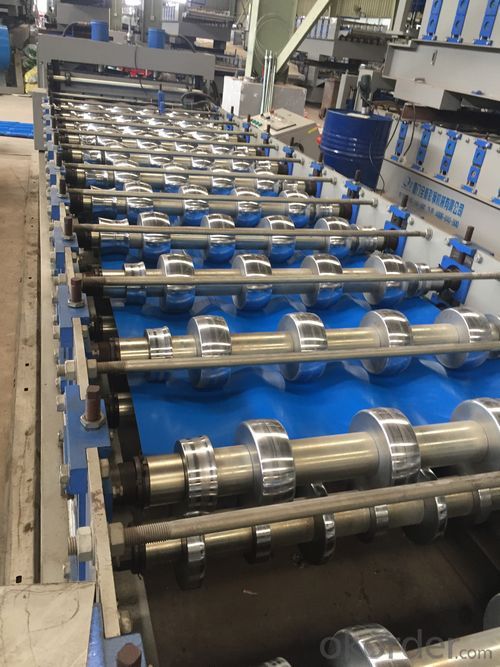

2. Main machine

With feeding material guide, body frame made from H350 type steel by welding;

Rollers manufactured from 45# steel,CNC lathes,Heat Treatment, hard Chrome Coated;

Shafts Diameter=ф75mm,precision machined

Gear/Sprocket driving, about 18-step to form

Main Motor=5.5KW , Frequency speed control

Forming speed approx.13-15m/min

3. Hydraulic Cutting device:

Cutter frame made from high quality 20mm steel plate by welding

Post cut, stop to cutting,Two pieces cutting blades,no blanking

Hydraulic motor: 2.2KW Cutting pressure: 0-12Mpa

Cutting tool material: Cr12, Heat treatment

4. PLC Control System

Control the quantity and cutting length automatically

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

PLC: Delta brand (Taiwan)

Inverter: Delta brand (Taiwan)

Touch Screen: WEINVIEW brand (Taiwan)

Encoder: KOYO brand (Japan)

Cut-to-length tolerance≤±2 mm

5. User's manual in English

- Q: What are the basic principles of warehousing?

- Warehouse management is the material of the warehouse and warehouse in the management, is to provide efficient storage service with storage mechanism in order to make full use of the storage resources planning, organization, control and coordination process.

- Q: What are the irrational aspects of warehousing in logistics?

- Integration of logistics function. Modern logistics will focus on other aspects of logistics and supply chain integration, including: logistics channel and logistics flow channel integration, channel integration, between the function of logistics integration, logistics and manufacturing integration etc..

- Q: What are the storage facilities and equipment included?

- When the warehousing industry exists as a format, logistics is an effective means to realize value-added services, and warehousing is an indispensable node in the logistics industry.The development of modern logistics industry needs the support of modern warehouse management, and the advanced technology of informatization and the guidance of information technology has become an effective way for the warehousing industry to modernize.

- Q: How to classify logistics facilities and equipment is more reasonable and scientific

- Logistics infrastructure mainly includes warehousing, carrying facilities, and computing and information communication equipment.Since human society has surplus production, there is storage, and warehouses are facilities for storing materials. In accordance with different angles, features and signs, the warehouse has its own warehouses, warehouses, public warehouses, bonded warehouses and bonded goods. Warehousing facilities play an important role in the whole logistics process:(1) the function of material storage. Any warehouse has a certain space to accommodate materials. The modern warehouse is not only a place for placing goods, but also a variety of facilities, with moderate storage and maintenance functions.(2) regulating the supply and demand of materials. There is a wide range of linkages between supply and demand as well as considerable complexity. When the supply and demand are unbalanced, the storage of the warehouse can act as a "reservoir" type.(3) regulating the function of material transportation. Transport capacity varies greatly because of the different means of transportation. The transportation contradiction caused by the difference of transportation capacity can be solved by the storage of materials, which is the function of material storage, regulation and transportation.(4) the function of material distribution. In modern logistics, warehouses in developed countries have been changed from original storage to distribution centers. That is to say to warehouse homework material sorting, matching, processing and circulation, in the new requirements, the warehouse has material distribution function.(5) the function of material saving. The role of material saving is indirectly manifested. Because people's production surplus is stored for a certain period of time without waste.

- Q: What are the responsibilities of the warehouse and logistics department?

- (1) responsible for drafting and revising the material storage management system of the company.(2) be responsible for the business instruction of other department's warehouse.(3) responsible for communication and coordination with all functional departments and related suppliers.

- Q: What is the warehousing logistics distribution center?

- Storage: first, to solve the seasonal difference between production plan and sale of seasonal time difference. The two is to solve the problem of balance between production and consumption, the need to ensure the normal distribution of the random, meet the needs of users, in the distribution center should not only maintain a certain amount of commodity reserves, but also to store goods kept in maintenance work, to ensure that the number of reserved commodities, ensure good quality. The distribution center serves as a number of production enterprises and commercial outlets (such as chain stores and supermarkets), distribution center according to user requirements timely with good goods sent to all to the hands of users, meet the needs of production and consumption. Distribution center process

- Q: What role does warehousing play in logistics?

- Warehousing is, first and foremost, a logistics activity, or logistics activity is the essential attribute of warehousing. Warehousing is not a production, not a transaction, but one of the logistics activities for production and transaction services. This shows that warehousing is only one of the logistics activities, logistics and other activities, warehousing should be integrated into the entire logistics system, should be associated with other logistics activities, and coordination. This is a significant difference from the past "warehouse management".

- Q: What is lean storage?

- With the development of enterprises, enterprises need to increase investment in all aspects, especially in warehousing, but also in warehousing, storage facilities, handling equipment, sorting equipment, barcode technology and other aspects of investment.Application of bar code technology can effectively solve the enterprise operation efficiency is low, the inventory control is difficult, difficult to manage their problems, and can easily cope with the market change constantly.Implementation of warehouse management informationization, we must establish the only encoding for each and every variety of products, and the use of bar code printer to make barcode label on the packaging of clothing or hang in the product tag.This will not happen again, the goods can not be found, missed the opportunity to sell the situation.

- Q: The disadvantages of traditional warehousing and the advantages of modern warehousing

- The socialization of warehouse management is not high. Even with the same enterprise, some internal logistics resources can not be shared. As the storage management is backward, the utilization ratio of storage facilities resources is less than 40%, which leads to the low efficiency of logistics

- Q: What is the storage fee?

- Warehousing cost is the material supply and marketing enterprises in the purchase of goods, acceptance, warehousing, storage of materials in the process of payment of all costs. Warehousing costs paid to the storage warehouse storage and transportation, as well as the subsidiary enterprise in the warehouse transfer handling, inspection, repair, maintenance, selecting and sorting, packaging, inventory loss, and wages, workers from the welfare expenses and other expenses.

Send your message to us

construction curving eave Roof Panel Forming Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords