Concrete Reinforced Steel Bar Corrosion Inhibitor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

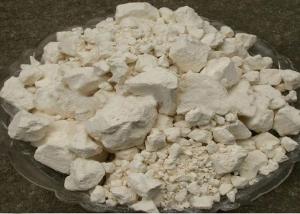

Reinforced Steel Bar Corrosion Inhibitor

(MNC-RI)

Description

MNC-RI is a high effective corrosion inhibitor for concrete reinforced construction. MNC-RI prevents or delays corrosion process towards reinforced steel, so as to extend reinforced concrete life span.

Technical Specifications

Table 1

Properties | Test Items | Standard Specifications | Actual Test Value |

Anti-corrosion performance | 1. Salt solution immersion test | Non-corrosion electric potential, 0 ~ 250mV | Non-corrosion electric potential, -179mV |

2. Wet & dry/cold & hot circulation test (60 times) | Non-corrosion | Non-corrosion | |

3. Electric chemistry displacement test | Standard | Standard | |

Effect to concrete property | 1. Compressive strength | Invariable | 125%( compare with reference sample) |

2. Anti-seepage performance | Invariable | 110%( compare with reference sample) | |

3. Initial setting time, min | -60-+120 (compare with reference sample) | -50 (compare with reference sample) |

Table 2

Items | Specifications |

Air Content, % | ≤4 |

Ratio of Bleeding Rate, % | ≤100 |

Setting Time Difference (initial and final), min | -90 +120 |

Compressive Strength, % | ≥100 |

28 days Shrinkage Rate, % | ≤135 |

Note: It complies with YB/T9231-98 < Reinforced Concrete Corrosion Inhibitor Standard>.

Main Performance

1. MNC-RI can prevent and delay the electric chemical process of the reinforced steel bar to extend the reinforced concrete service life.

2. Test should be taken before mixing with air entraining admixture. When temperature is higher than 25 degree C, it has accelerating, rapid setting effect and also slump loss effect.

3. MNC-RI has water reducing effect while keeps flowability.

Application range

MNC-RI is applied in chloride-based corrosion environment constructions, such as maritime and coastal works, and other constructions which containing chloride.

Directions

1. Recommended addition rate: C ×3.0%, say 100kg cement with 3 kg of MNC-RI.

2. (1). While applied in moderately corrosive environment, such as industrial and civil constructions and bridges, the recommended addition rate is 4 ~ 8 kg/m3. (2). While applied in heavy corrosive environment, such as maritime and coastal constructions, the recommended addition rate is 8 ~ 12kg/m3.

3. Regarding to the mixing procedure, first mix MNC-RI, cement and aggregate with mixer, than add water into it. The mixing time can be prolonged properly to ensure homogeneity.

4. Do test before adding any other admixture into the concrete, so as to make sure whether the concrete is adoptable or not, air-entraining water reducing admixture is not allowed to be added.

Package, Storage & Handling

◆ MNC-RI is packed in woven fabric bag with plastic liner. Net weight: 40kg +/- 0.13 kg.

◆ Cautions should be taken to prevent packages from being torn by sharp-ended objects while being transferred or delivered. When being contaminated by high humidity or moisture in case of leakage, it can be prepared in prescribed ways for further use without surrendering any effect.

◆ It should be stored in a dedicated warehouse which is well-ventilated and dry, away from flammable and combustible items, especially open flames. The shelf life is one year.

Send your message to us

Concrete Reinforced Steel Bar Corrosion Inhibitor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords