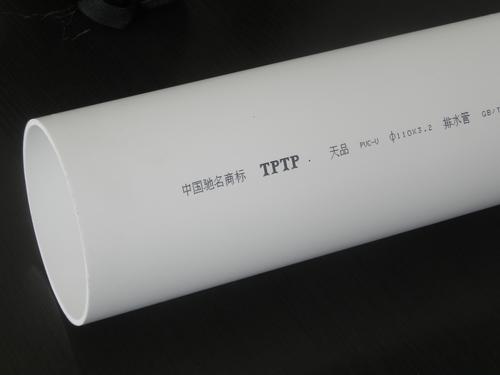

Composite PVC Drainage Pipe Fittings

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000米 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC pipe is the health grade polyvinyl chloride (PVC) resin as the main raw material, adding proper amount ofstabilizer, lubricant, bulking agent, hyperchromic agent by plastic extrusion molding and injection molding machine,cooling, curing, shaped by process, inspection, packaging, in order to complete the pipes, pipe fittings production.

1 pipe surface hardness and tensile strength and high safety coefficient, pipeline.

2 good ageing resistance, the normal service life of up to 50 years.

3 pipeline of inorganic acid, alkali, salt, excellent corrosion resistance, suitable for industrial wastewater discharge and transport.

The 5 material has high oxygen index, selfextinguishing.

6 pipe line expansion coefficient is small, is affected by the temperature 0.07mm/ ℃, small deformation.

Thermal conductivity and low modulus of elasticity, anti frozen performance compared with cast iron drainage pipe.Thermal conductivity and low modulus of elasticity, anti frozen performance compared with cast iron drainage pipe.

The 7 pipes, pipe fittings are connected by adhesive, the construction method is simple, convenient operation, high installation efficiency.

- Q: Can composite pipes be used in chemical processing plants?

- Yes, composite pipes can be used in chemical processing plants. Composite pipes are known for their excellent chemical resistance, corrosion resistance, and durability. They can handle a wide range of chemicals and offer better performance compared to traditional metal pipes. Additionally, composite pipes are lightweight, easy to install, and require minimal maintenance, making them a suitable choice for chemical processing plants.

- Q: How are composite pipes different from traditional pipes?

- Composite pipes are different from traditional pipes in that they are made from a combination of materials, such as fiberglass, carbon fiber, and resin. This makes them lighter, stronger, and more resistant to corrosion compared to traditional pipes, which are typically made from materials like metal or plastic. Additionally, composite pipes have better thermal and electrical insulation properties, making them suitable for a wide range of applications in industries such as oil and gas, water supply, and chemical processing.

- Q: Do you need oil brushing for galvanized steel pipe and steel plastic composite pipe?

- Plastic steel composite pipe, the product of seamless steel pipe, welded steel pipe as the base pipe, painted on the interior of high adhesion, anti-corrosion, food grade hygiene polyethylene powder coating or epoxy resin coating. By pretreatment, preheating, internal coating, leveling, postprocessing technology made in water supply galvanized plastic composite pipe, is the upgrading of traditional galvanized pipe, steel plastic composite pipe with threaded connection.

- Q: What does "plastic steel composite pipe" mean?

- By pretreatment, preheating, internal coating, leveling, postprocessing technology made in water supply galvanized plastic composite pipe, is the upgrading of traditional galvanized pipe, steel plastic composite pipe with threaded connection.

- Q: Plastic pipe and plastic lined steel pipe has what difference?

- Definition: lining plastic pipe is based on steel pipe, the inner and outer surface has been treated, galvanized with paint or spray paint, lined with polyethylene plastic or other lining plastic steel composite products.Classification: plastic lined steel pipe cold water and hot water pipe lined with plastic lining plastic pipe, plastic lining plastic pipe

- Q: Can composite pipes be used for steam distribution systems?

- Yes, composite pipes can be used for steam distribution systems. Composite pipes, typically made of materials like fiberglass or carbon fiber, offer excellent resistance to high temperatures and pressures, making them suitable for steam applications. They are lightweight, corrosion-resistant, and have low thermal conductivity, which helps minimize heat loss during steam distribution. Additionally, composite pipes are known for their durability and long lifespan, providing a reliable and cost-effective solution for steam distribution systems.

- Q: Can composite pipes be used for both residential and industrial applications?

- Yes, composite pipes can be used for both residential and industrial applications. Composite pipes are versatile and can withstand high pressure and temperature, making them suitable for various applications in both residential and industrial settings. They are commonly used in water supply systems, irrigation, gas distribution, and chemical processing plants.

- Q: Hot galvanized steel (PE Village plastic) composite pipe and PE100 water supply pipe (sdr11) what is different, we usually talk about steel pipe refers to that?

- Hot dip galvanized steel plastic composite pipe is PE plastic lining, plastic lining is galvanized pipe, PE pipe is polyethylene plastic pipe, galvanized steel plastic composite pipe with threaded pipe connection, polyethylene plastic pipe by hot melt, fused or flange connection.

- Q: Can composite pipes be used for power generation plants?

- Yes, composite pipes can be used for power generation plants. Composite materials offer several advantages such as high strength-to-weight ratio, corrosion resistance, and insulation properties, making them suitable for various applications in power plants. Composite pipes can be used for transporting fluids, such as water or steam, within the power generation plant, contributing to efficient and reliable operations. Additionally, their durability and long lifespan make them a cost-effective choice for power generation plants.

- Q: Can composite pipes be used for food and beverage processing?

- Yes, composite pipes can be used for food and beverage processing. Composite pipes are often made from materials such as fiberglass, carbon fiber, or plastic, which are resistant to corrosion and chemical reactions. They can offer advantages such as lightweight, durability, and flexibility, making them suitable for transporting food and beverages. Additionally, composite pipes can meet the necessary health and safety standards required for food and beverage processing.

Send your message to us

Composite PVC Drainage Pipe Fittings

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000米 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords