Composite Pipes - FRP Pipes Filament Winding FRP Pipe with Sand Filler

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

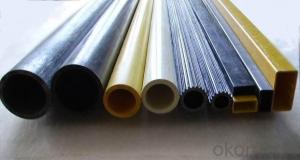

1. Structure of Filament Winding FRP Pipe Description

Production Range: Diameter: DN 40-800mm, Pressure Rating: PN 3.5-25Mpa

Implemented Standards: 1) API15HR 2) API15LR

Temperature-resisting Grade:

Long-term working temperature range of anhydride cured epoxy system ≤65°C, the maximum temperature 80 °C.

Long-term working temperature range of amine cured epoxy system ≤93.3°C, the maximum temperature 135°C.

The minimum working temperature range of Epoxy FRP pipe products ≥-35°C

2. Main Features of Filament Winding FRP Pipe

1) High corrosion resistance

2) Excellent fatigue durability, 20 years design service life.

3) Strong bearing, high safety coefficient

4) Light weight, easy installation

5) Fine tightness connected with steel pipe

6) High, middle, low pressure rating satisfy different medium delivery.

7) No electrical conductivity, smooth internal surface and low friction coefficient, high delivery efficiency.

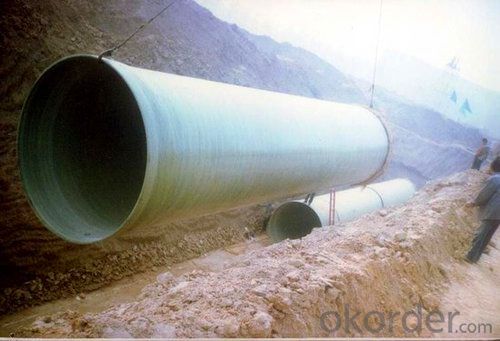

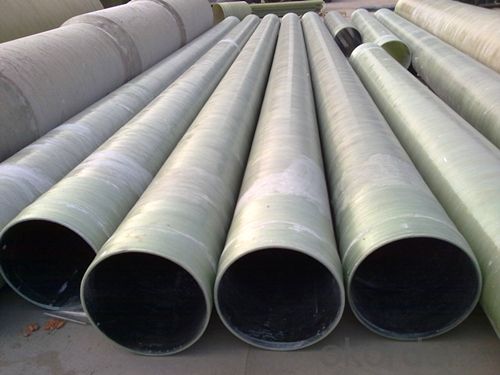

3. Filament Winding FRP Pipe Images

4. Filament Winding FRP Pipe Application

1) Oil or gas transportation lines.

2) Chemical treatment and sewage pipelines.

3) Fluid transportation lines of high, medium and low pressures.

4) Oily water injection lines.

5) Injection lines for tertiary recovery(Injection of polymer, CO2 , NaOH etc.).

6) Tubing for oil producers, tubing for injectors of salty, chemical or oily water, CO2 and polymer.

5. FAQ of Filament Winding FRP Pipe

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

One of the leading manufacturers and suppliers specializing in FRP pipe products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: What are FRP pipes made of?

- The wall of the pipe is smoothReduce flow resistance, increase flow speed and reduce energy consumption. Compared with the same size steel pipe, the flow rate of the same volume can be increased by about 10%, and no fouling and long-term use can not reduce the flow rate. The protection of cables in interference and heavy corrosion environment is better.

- Q: FRP duct material plan is how to mention?

- Process design according to user's requirements and choose what material to use. Then according to the drawings and process, calculate the amount of various materials. According to the delivery date and production schedule, you can write the material schedule.

- Q: Do I need CCC certification for ventilated GRP?

- Usually fiberglass, air conditioning, ventilation pipes will have insulation requirements, the general need not heat preservation.

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- Usually with aluminum or iron sheet, with glass or steel, or the first time, I'm afraid the toughness is not enough.

- Q: What kind of material is the pipe of the pipe that installs the pressure transmitter of GRP conduit? Is it fiberglass or carbon steel?

- It is generally assumed that it is made of glass fiber reinforced plastic. The main pipe is made of glass fiber reinforced plastic. The medium is corrosive. Other materials must not be suitable

- Q: What is the difference between glass tube, sand pipe and glass tube?

- Glass reinforced plastic sand pipe is actually in the production of glass fiber reinforced plastic pipe, in the middle to increase a layer of sand layer, the purpose is to increase the rigidity of the pipeline.

- Q: How to repair and repair the broken hole of GRE glass fiber reinforced plastic pipe?

- Place an iron or glass piece of steel on a broken hole like a bicycle tire, then use three oil, two cloth, or five oil three cloth;

- Q: What's the difference between glass fiber reinforced plastic pipe and glass fiber reinforced sand pipe?

- Sand sandwiched glass fiber reinforced plastic pipes only have more than one sand sandwiched with glass fiber reinforced plastic pipes, and sand layer can be understood to replace glass fiber with quartz sand. The sand pipe with the same thickness is compared with the glass fiber reinforced plastic pipe, but the sand holding pipe is cheap, but the strength is poor; and the glass steel pipe is opposite.

- Q: Uneven settlement of the foundation, can lead to glass fiber reinforced plastic underground water pipes burst, what is the principle?

- Can cause rupture. FRP material originally resistant to pressure better, tensile, shear resistance is poor, the foundation sinking is shear, I want to sink more than 5 cm, if the soil around the pipeline is compacted, it may break

- Q: How long is the service life of glass fiber reinforced plastic pipes?

- The glass fiber reinforced concrete grille is made of three kinds of polypropylene, polyvinyl chloride and ethylene propylene copolymer. The FRP grille is only half the size of the glass, saving transportation, unloading, mounting, and supporting the cost of the frame.

Send your message to us

Composite Pipes - FRP Pipes Filament Winding FRP Pipe with Sand Filler

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords