Composite Glass Reinforced Epoxy (GRE) Pipe for Brine Water Pipelines

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 200000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GRE Pipe Description

GRE pipe is short for Glass Reinforced Epoxy pipe.

Generally high pressure FRP pipe, mainly used in oil field oil, water, polymer injection pipelines, natural gas transportation, urban drainage, drinking water pipelines, chemical industry, brine pipeline, fire pipelines and other fields.

Main Application:

1. Pipeline of brine, water and crude oil

2. Pipeline of polymer solution

3. Collection pipeline of crude oil and natural gas

4. Oilfield sewage, chemical sewage and waste water disposal pipe

5. Water distribution system

6. Petrochemical technical pipeline

Main Features of the GRE Pipe

1. High physical-mechanical character

2. High corrosion-resistant capability

3. Excellent heat-Rsistant capability; the mormal working temperature is 80 degree, which can meet the requirement of technology of oil extraction and effusion.

4. High-pressure-resistant capability: normal operating pressure grade from 3.5MPa to 25MPa.

5. Light weight

6. Long life, the designed service life is not shorter than 20 years.

7. High flow property of medium, non scaling, non depositing wax, will not being clogged.

8. Screw threaded connections and convenient installation.

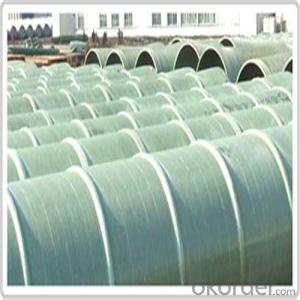

GRE Pipe Images

GRE Pipe Specification

1.Diameter:1.5inches(38mm)--24inches(600mm)

2.Pressure Grade:3.5---25MPa

3. Production Length: 9m or 11.8m

4. Connection Methods: API screw thread seal with aquaseal connection of eight rounds or ten rounds

FAQ of GRE Pipe

Q: What are the basic characteristics of the glass tube

Excellent physical and mechanical properties

Density fiberglass pipe is usually 1.8-2.1g / cm3, about 1/4 of steel, are higher than that of steel, cast iron and plastic than strength. The weight of the glass tube is generally greater than the same size steel 1/3 superior physical and mechanical properties; in addition, the thermal expansion coefficient of the glass tube and steel roughly, only 0.5% of the thermal conductivity of steel, is a good thermal and electrical insulation material.

Q: Is GRE Pipe chemical resistant with a long life?

GRE pipe has a special resistance to chemical corrosion in pipes criss-cross, dotted down environment, you can choose a different corrosion-resistant pipes according to the requirements of the medium.

Q: How are the hydraulic properties?

Water is one of the important mechanical properties of glass pipe. Hydraulic fluid excellent characteristics mean little head loss, you can use a smaller diameter or smaller power pump, thereby reducing the initial investment pipeline projects, save energy, reduce operating costs.

- Q: Glass fiber reinforced plastic pipe to withstand 1.0MPa pressure, pipe wall to do how much thickness?

- Glass tube wall thickness is generally determined by the manufacturer design, with stereotypes products and sequences, you can choose according to the pressure level.

- Q: What kind of material does glass steel ship honeycomb board use?

- Analysis of glass steel tube and glass steel tube cellular communication used in communication network construction, is currently used PVC bellows and PVC honeycomb tube, pipe and pipe crossing is the use of plastic pipe or galvanized steel pipe.

- Q: The difference between GRP cable duct and PVC cable pipe

- The biggest difference is that the material is different, and the other areas of use are different

- Q: Which is better, PVC pipe and GRP pipe?!

- To see the composition of your gas, fiberglass can be chosen according to the requirements of different resins for corrosion protection, and PVC for some gases are not corrosion-resistant,

- Q: How much is a glass fiber reinforced plastic sand pipe socket pipe fitting?

- Glass reinforced plastic sand pipe can increase rigidity by adding sand layer to the middle layer of pipe wall, which can meet any reasonable rigidity requirement of users. Another advantage of gfrpmp stiffness is bending deformation ability is very strong, for example, glass steel 5000Pa stiffness of sand in deformation of 20% cases, no delamination damage, and after unloading can restore the concrete pipe due to large deformation may be unable to bear have broken gfrpmp ring 150MPa ~ to the apparent flexural strength 450MPa, tensile and compressive and flexural strength of the concrete pipe were borne by steel and concrete, the apparent flexural strength is still far below the gfrpmp, only 8.5% ~ gfrpmp 26%. Generally, the service life of the drained glass fiber reinforced plastic sand pipe can be more than 50 years, and it is more than 2 times that of reinforced concrete pipes and other drainage pipes.

- Q: What's the process of continuous winding glass fiber reinforced plastic sand pipe?

- On line inspection: the pipe being cut and grinded is delivered to the water pressure test machine through the conveyor. After the test is qualified, the pipe joint which has been tested by hydraulic pressure is sent to the pipe joint installation machine for joint installation.

- Q: What are the construction methods of glass fiber reinforced plastic paint anticorrosive pipes?

- Oil and gas pipelines used for twenty years, basically no corrosion phenomenon. As part of a group of coal tar epoxy primer and topcoat are based on epoxy resin and coal tar as the main film-forming material, add a variety of anti rust paint, insulating filler, toughening agent, leveling agent, diluent, anti settling agents and other materials, the B component is modified amine curing agent or curing agent the main material, adding fillers. When the product is sold, the A and B parts are supplied together, and the mixture is mixed in proportion during construction.

- Q: How to improve the compressive strength of waste glass fiber reinforced plastic profiles (such as square tubes) should be started with resin, curing agent, glass fiber or other aspects!

- Use a high strength resin type;

- Q: What is the thickness of all types of FRP pipes?

- DN200, DN150, DN100, DN80 pipe, polyurethane foam pad, 50mm thick shell, glass steel, thickness 3mm.

- Q: A basic overview of FRP pipes

- FRP pipes are used in petroleum, chemical and drainage industries. Glass fiber reinforced plastic pipeline production in China has developed rapidly, and the quantity has been increasing year by year, and the scope of application and departments are becoming wider and wider.

Send your message to us

Composite Glass Reinforced Epoxy (GRE) Pipe for Brine Water Pipelines

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m

- Supply Capability:

- 200000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords