Composite Fiberglass Reinforced Plastic (FRP/GRP) Pipes API Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pipe Description

Made from the high quality corrosion resistant resin and continuous fiber winding without alkali, filament winding FRP pipe possesses the characteristics of lightness, high strength, distinguished corrosion resistance and expedient installation and maintenance etc.,

FRP Pipes were applied widely in the oil-field system of sewage treatment, electrical plant water circulation, water pipe with electric magma and projects of chemical engineering, metallurgy, and medicine processing etc.

our company (headquarter in Jiangsu Province) has been the No. 1 in exporting composites products domestically, annual capability of 100,000 tons for pipes & tanks as well as 10,000 pieces of wind turbine blade, with branches in Thuringia of Germany, Liaoning province, Neimenggu Province, Gansu Province, Xinjiang Province and Sichuan Province etc.

We are the exclusive FRP manufacturer with rich experiences in cooperating with foreign companies worldwide, the only supplier that provides large-diameter FRP pipes to the nuclear power station. Sole company owning finite element analysis in China. 20 production lines are in good operation.

Main Features of the FRP Pipe

Corrosion-resistant

Light weight

Long standard lengths

Extremely smooth bore

Precision sealability

Flexible manufacturing

High technology pipe design

High technology pipe manufacturing system producing pipe that complies to stringent performance standards (AWWA, ASTM, DIN, EN,BS, etc.)

FRP Pipe Application

1)drinking water transmiting

2)sewage pipeline,rainwater pipelin

3)angricultural irrigation

4)seawater desalination system

5) other kinds of liquid transmiting

6)municipal engineering construction

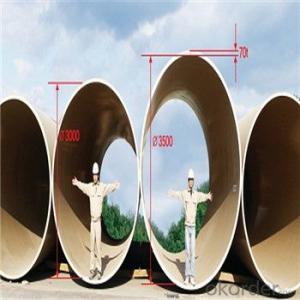

FRP Pipe Images

FRP Pipe Specification

Diameter: DN300-4000

Pressure:PN6-25

Standard length: 6m, 12m

Execute standard:JC552,ASTMD2996

Management System & Certificates

Management system: ISO9001, ISO14001, OHSAS18001,

Performance standards: ASTM D3262, D3517, D3754/AWWA C950, M-54/China Standard B/21238, JC552, CECS190, CECS129; DIN16868/ BS 5480;

WRAS Certificate, API Certificate, Installation Qualification.

Caesar II is applied for stress analyzing of piping system, AFT impulse is used for analysis of water hammer. Meanwhile we can supply finite element analysis to the customer.

FAQ of FRP Pipe

Q: What is fiberglass composite?

A: Fiberglass composite is a laminate made from glass fibers or filaments and thermosetting resin. It is commonly known as RTRP, RTMP, FRP, GRP, GRE and GRV.

Q: Are fiberglass pipes fragile?

A: Due to the elastic nature of the resin which holds the clothlike glass fibers together, fiberglass is strong and flexible. FPI products meet the rigorous "Impact Test" requirements of the international standard e.g. BS, API, ...

Q: What is the trade information

A: Trade terms:FOB,CIF,EXW

Payment terms:T/T,L/C

Shipping:By sea,by air and by express delivery

- Q: Designed to support FRP pipes, is it m or mm?

- Glass fiber reinforced plastic cable protection tube chemical composition: GRP winding pipe is a kind of glass fiber reinforced plastic product. With the continuous development of glass fiber reinforced plastic molding technology, FRP products have been widely used in various fields. FRP products have the advantages of light quality, high strength, corrosion resistance, long service life, flame retardant, high temperature resistance and various forms of products. Therefore, the industry gradually increase the use of glass fiber reinforced plastic products, which will be reinforced FRP mechanical properties and molding process put forward higher requirements. The forming process of FRP determines its shape, property and application prospect. The mechanical properties of glass fiber reinforced plastics determine whether their products can be widely used in industries with higher mechanical properties. Fiberglass reinforced plastic square tubes can replace some metal pipes used in industrial and civil fields, such as central air conditioning, chemical plants, etc. but glass fiber reinforced plastic square tube products are not common in the market. This is mainly due to the existence of poor strength, easy deformation and other defects.

- Q: What is the stiffness of FRP pipe?

- Ring stiffness refers to a technical index of FRP pipes subjected to external pressure.

- Q: Is it useful to make gas pipelines with glass steel pipes? Or the idea that the technology is mature?

- I don't think it's enough, because the strength of FRP is not enough, it can easily be brittle and easily perforated in the field for a long time!

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- Usually with aluminum or iron sheet, with glass or steel, or the first time, I'm afraid the toughness is not enough.

- Q: Why more and more people choose FRP pipe?

- And the price ratio of FRP pipe is not much cheaper, and although the hardness of concrete pipe although FRP pipe to be hard, but the toughness and tensile strength is poor, the pressure is not good, and the cost is expensive, because more and more people use glass steel, and the price is expensive, with longer life.

- Q: Is it possible to touch the water when the glass fiber reinforced plastic pipe is polished?

- Because the resin curing mechanism of FRP products is resin, resin agent, resin curing agent together to react, and release a lot of heat, this process does not affect the curing process because of a small amount of water and at the same time, if you have a little bit of water molecules would because of the large amount of heat emitted by evaporate, so does not affect the bonding of glass and steel that will not affect the glass steel pipe interface

- Q: What is the structure and function of glass fiber reinforced plastic lining?

- The role of FRP lining, corrosion protection, generally attached to the carbon steel container wall, can avoid the use of stainless steel, saving costs. FRP can resist acid and alkali corrosion, PH2-12 or so no problem, but not high temperature, the temperature is higher than 80 degrees, more dangerous, will dissolve.

- Q: How to connect glass fiber reinforced plastic sand pipe?

- The quality of the connection of glass reinforced plastic sand pipe pipe directly affects the quality of the pipeline. The connection forms between the pipes include 3 forms: socket, butt joint and flange connection.

- Q: What are the advantages of FRP pipes?

- Light weight, corrosion resistance, aging resistance, long service life,

- Q: What kind of diamond saw blade for cut glass steel pipe?

- Glass fiber reinforced plastic pipe is also called glass fiber winding sand pipe (RPM pipe). Mainly to the glass fiber and its products as reinforcing material, polymer composition of unsaturated polyester resin, epoxy resin as basic material, quartz sand and calcium carbonate and other inorganic non-metallic particles as filler materials as the main raw material. The standard effective length of the tube is 6m and 12M, and the production methods include fixed length winding process, centrifugal casting process and continuous winding process of three kinds. Classification can be carried out according to the product process method, pressure grade PN and stiffness grade SN.

Send your message to us

Composite Fiberglass Reinforced Plastic (FRP/GRP) Pipes API Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords