Color Steel Material Shed

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mark & model : The material sheds are made up by light steel structure through welding and roofs are covered by color steel sheet. Light steel structure ensures the excellent windproof and shockproof performance of the shed. The components of material shed are jointed on site which are easy to transport and decrease the cost. Large-slope roof adopts structural waterproofing design.

Origin : Asia and Pacific Area China

Quality standard : International

Submit date : 2013-09-23

H.S.Classification : Furniture & Toys Furniture 9406 Prefabricated buildings

Product profile : Color Steel Material Shed

Size: No more than 20m or multi-span

Notes of Product:

1.The goods shed series product is composed of light steel structure through welding and the roof is covered by single color steel plate.

2.The steel structure ensures the shed building with excellent performance of wind resistance and shock resistance.

3.All components of shed building could be jointed on site, which are featured as convenient transportation, easy installation and cost cutting.

4.The large-slope roof adopts structural waterproof design to improve the drainage.

5.The product is suitable to such project constructions as railway, highway, water conservancy and hydropower.

Quality Standard: Industrial Standard

Origin: China

Commodity Classification: Color Steel Shed

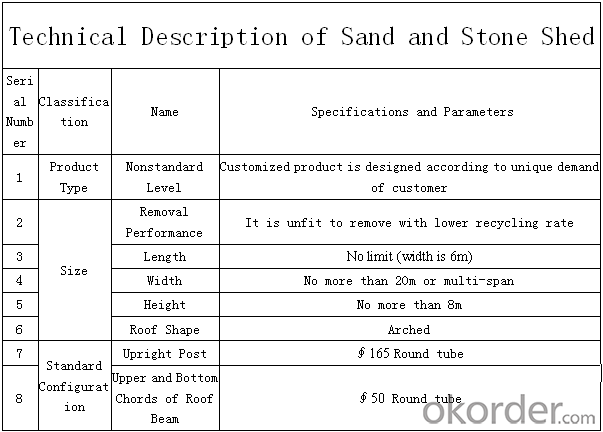

Descriptions:

1.Material Descriptions

1.1 Wallboard: No external enclosing material. The single plate enclosure is available if needed.

1.2 Roof Board: The roof board adopts 900-type color painted steel strip with the thickness of 0.35mm.

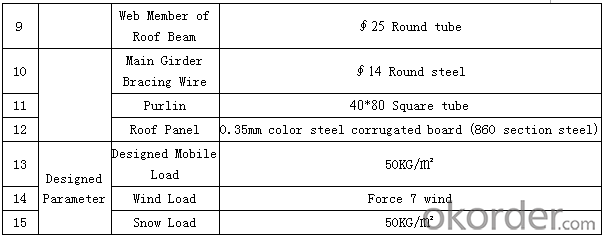

1.3 Roof Truss: The arched roof truss is composed of∮50 and∮25 round steel pipes through welding. The spacing between roof trusses is 6m. The material of steel is Q235 and the component surface is processed by anti-rust treatment.

1.4 Upright Post: The upright post is made of∮165 round steel pipe. The spacing between upright posts is 6m. The material of steel is Q235 and the component surface is processed by anti-rust treatment.

1.5 Purlin: The purlin is made of 80*40 rectangular steel pipe. The spacing between purlins is 0.6m. The material of steel is Q235 and the component surface is processed by anti-rust treatment. 2.Building Structure

The main structure of prefabricated house is composed of upright posts and arched roofs.

2.1 Wall: No external wall enclosing material (Optional)

2.2 Roofing: The roof is composed of roof panels and roof trusses.

2.2.1 The external roof is made of single color steel plate with the functions of waterproofing and keeping the room away from direct sunshine.

2.2.2 The roof structure is composed of trusses, purlins and diagonal bracings.

3. Components Connection

3.1 Connection between roof panels: The roofing sheet is the overlapped panel.

3.2 Profiled Fittings Connection:

3.2.1 Color Steel Profiled Fitting: The roof supporting profiled fitting and other counterparts are made of 0.4mm-thick color painted steel strip.

3.3 Hardware for Connection:

3.3.1 The aluminum rivets are used for the connection between color steel profiled fittings as well as between color steel profiled fitting and steel frame.

3.3.2 The self-tapping screws (hexangular drilling screws) are used for the fixing of purlins and connection between steel frames and roof panels.

3.3.3 The primary beam and upright post are connected by bolts or welding.

3.3.4 The foundation trench and foundation as well as the upright post and foundation are connected through expansion bolts or welding.

Features:

1. Aesthetic Appeal:

The roofing of goods shed and steel shed is single color steel plate which is quite aesthetic.

2. Easy Installation:

It is easy to install the shed, the components of which are connected by bolts, rivets and self-tapping screws.

3. Waterproofing:

The larger slope of the external roof is good for drainage.

4. Diversified Sizes:

The workability of materials used in the shed is excellent which could be designed and customized according to the unique demand of customers.

5. Application:

The goods shed and steel shed are featured as aesthetic appearance and comfortable living condition which are widely used for the material storage and processing location in such fields as construction, railway, highway, water conservancy etc.

Parameters:

Send your message to us

Color Steel Material Shed

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords