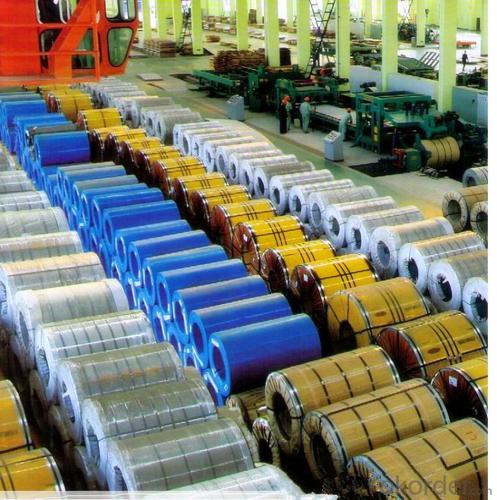

Cold Rolled Stainless Steel Coil 304 Wide/Narrow Strip 2B/BA Finish

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cold Rolled Stainless Steel Coil 304 Grade Narrow/Wide 2B/BA Finish

Packaging Detail:standard export packing or as customer's requirements

Delivery Detail:7-15 days after the order

MOQ: 100mt

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | 304 | Thickness: | 0.3-3.0mm |

Place of Origin: | China Mainland | Brand Name: | CNBM | Model Number: | 304 |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | 2B, BA |

Application: | Medical instruments, building, chemical food industry agriculture | Width: | 500-2000mm | Length: | Coil |

finish: | 2B, BA | item: | 304 cold rolled stainless steel coil | density: | 7.93 |

Cold Rolled Stainless Steel Coil 304 Grade Narrow/Wide 2B/BA Finish

Chemical composition: |

| ||||||

C | Si | Mn | Cr | Ni | S | P | |

≤0.07 | ≤1.0 | ≤2.0 | 18.0~20.0 | 8.0~11.0 | ≤0.03 | ≤0.035 | |

mechanical properties: |

| ||||||

Tensile strength σb (MPa) | Conditions yield strength 0.2 sigma (MPa) | Elongation δ5 (%) | Section shrinkage (%) | Hardness | |||

520 | 205 | 40 | 60 | ≤1 | |||

- Q: Can stainless steel strips be used in the pharmaceutical manufacturing industry?

- Yes, stainless steel strips can be used in the pharmaceutical manufacturing industry. Stainless steel is widely used in the pharmaceutical industry due to its excellent corrosion resistance, durability, and hygienic properties. Stainless steel strips are commonly utilized in the manufacturing of various pharmaceutical equipment such as tanks, vessels, piping, and machinery. These strips offer high resistance to chemicals, heat, and moisture, making them suitable for use in the pharmaceutical manufacturing process where strict hygiene and cleanliness standards are required. Additionally, stainless steel is easy to clean and maintain, ensuring the prevention of contamination and maintaining a sterile environment. Overall, stainless steel strips are a preferred choice in the pharmaceutical industry for their reliability, longevity, and compliance with regulatory standards.

- Q: Can stainless steel strips be used in solar energy systems?

- Yes, stainless steel strips can be used in solar energy systems. Stainless steel is a popular material choice for various components in solar energy systems due to its excellent corrosion resistance, durability, and high-temperature resistance. These properties make it suitable for use in both indoor and outdoor solar installations. Stainless steel strips can be used in solar panels, mounting structures, frames, and brackets, as they provide structural support and ensure longevity in harsh weather conditions. Additionally, stainless steel's low thermal expansion coefficient allows it to maintain its shape and dimensional stability over time, making it an ideal material for solar energy systems.

- Q: How do stainless steel strips perform in the presence of sulfuric acid?

- Under certain conditions, sulfuric acid generally does not corrode stainless steel strips. The performance of stainless steel when exposed to sulfuric acid is influenced by various factors, including the acid's concentration and temperature, the grade of stainless steel, and the duration of exposure. At room temperature, stainless steel is typically resistant to weak sulfuric acid solutions (up to 10%). The natural passive film on the stainless steel surface provides excellent corrosion protection under these circumstances. The specific grade of stainless steel can affect its resistance, with austenitic stainless steel (e.g., 304 and 316) offering better corrosion resistance compared to ferritic or martensitic grades. However, as the concentration or temperature of sulfuric acid increases, the corrosion resistance of stainless steel may diminish. Higher concentrations (above 10%) or elevated temperatures can lead to localized corrosion, such as pitting or crevice corrosion. To combat this, higher alloyed stainless steels, like duplex or super duplex grades, are commonly employed as they offer improved resistance to sulfuric acid. It is crucial to note that prolonged exposure to sulfuric acid can eventually cause corrosion in stainless steel. To minimize the risk, it is advisable to limit the exposure time and acid concentration. Regular maintenance and proper cleaning practices can also help preserve the corrosion resistance of stainless steel in the presence of sulfuric acid.

- Q: How do stainless steel strips resist embrittlement in high-temperature applications?

- Stainless steel strips resist embrittlement in high-temperature applications due to their unique composition and properties. The presence of elements such as chromium, nickel, and molybdenum enhances their resistance to oxidation, corrosion, and high-temperature embrittlement. These elements form a protective layer on the surface of stainless steel, preventing diffusion of harmful substances and maintaining its structural integrity even at elevated temperatures. Additionally, the formation of stable carbides helps to retain ductility and toughness, ensuring that stainless steel strips can withstand high-temperature conditions without becoming brittle.

- Q: Can stainless steel strips be used for heat exchanger tubes?

- Yes, stainless steel strips can be used for heat exchanger tubes. Stainless steel is a popular choice for heat exchanger applications due to its excellent corrosion resistance, high temperature resistance, and durability. Stainless steel strips can be formed into tubes of various shapes and sizes to accommodate different heat exchanger designs and requirements. Additionally, stainless steel offers good thermal conductivity, allowing for efficient heat transfer in the exchanger. Overall, stainless steel strips are a suitable and commonly used material for heat exchanger tubes.

- Q: What are the recommended precautions for welding 111 stainless steel strips?

- When welding 111 stainless steel strips, it is important to take certain precautions to ensure safety and achieve quality welds. Here are some recommended precautions to follow: 1. Ensure proper ventilation: Welding stainless steel can release fumes and gases, including chromium and nickel, which can be harmful if inhaled. Therefore, it is necessary to work in a well-ventilated area or use local exhaust ventilation to remove the fumes from the work area. 2. Wear appropriate personal protective equipment (PPE): Always wear a welding helmet with a proper shade lens to protect your eyes from the intense light and harmful radiation emitted during welding. Additionally, wear welding gloves, a flame-resistant jacket, and safety boots to protect your skin from sparks, molten metal, and heat. 3. Use the correct welding technique: Stainless steel is prone to distortion and warping during welding due to its high thermal conductivity. Therefore, it is recommended to use a low heat input technique such as TIG (Tungsten Inert Gas) welding, which allows for better control over the heat input. This helps to minimize distortion and achieve quality welds. 4. Clean the surface properly: Prior to welding, ensure that the stainless steel strips are clean and free from any contaminants such as dirt, grease, or oils. Use a suitable cleaning agent and a stainless steel wire brush to remove any surface impurities. This helps to prevent weld defects and ensures good adhesion between the strips. 5. Use the correct filler material: When welding stainless steel, it is important to use the appropriate filler material that matches the grade of the base metal. For 111 stainless steel, commonly known as AISI 304 or 18-8 stainless steel, a filler material such as ER308L or ER316L is recommended. These filler materials provide good corrosion resistance and mechanical properties to the weld. 6. Monitor the heat input: Excessive heat can lead to the formation of carbide precipitation and intergranular corrosion in stainless steel. It is crucial to monitor and control the heat input during welding to avoid these issues. This can be achieved by adjusting the welding parameters such as current, voltage, and travel speed. 7. Post-weld cleaning and passivation: After welding, it is important to clean the weld area to remove any heat-tint or oxide scale formed during the welding process. Use a suitable cleaning agent and a stainless steel wire brush to clean the weld area. Additionally, passivate the weld by applying a suitable passivation solution to restore the stainless steel's corrosion resistance. By following these recommended precautions, you can ensure a safe working environment, minimize weld defects, and achieve high-quality welds when welding 111 stainless steel strips.

- Q: What is the maximum length available for stainless steel strips?

- The maximum length available for stainless steel strips can vary depending on the manufacturer and the specific requirements of the customer. However, in general, stainless steel strips can be produced in lengths ranging from a few inches to several feet. Some manufacturers may be able to produce even longer strips, depending on their capabilities and equipment. It is important to consult with the manufacturer or supplier to determine the maximum length available for stainless steel strips that meet your specific needs.

- Q: Can stainless steel strips be used in outdoor applications?

- Certainly! Outdoor applications can utilize stainless steel strips. Due to its exceptional resistance to corrosion, stainless steel is an excellent choice for outdoor environments that may encounter moisture, humidity, and other elements. Moreover, stainless steel possesses remarkable durability and strength, making it suitable for a range of outdoor applications, including construction, signage, and equipment. Regardless of whether stainless steel strips are employed for decorative purposes or functional use, they are capable of withstanding harsh outdoor conditions and delivering long-lasting performance.

- Q: Are stainless steel strips resistant to pitting and crevice corrosion?

- Yes, stainless steel strips are generally resistant to pitting and crevice corrosion. Stainless steel is known for its corrosion resistance properties, and it contains a significant amount of chromium, which forms a protective layer on the surface of the steel when exposed to oxygen. This layer, called the passive film, prevents the steel from reacting with its environment and protects it from corrosion, including pitting and crevice corrosion. However, the resistance to corrosion can vary depending on the specific grade and composition of stainless steel, as well as the conditions it is exposed to. It is important to choose the appropriate grade of stainless steel for the specific application to ensure optimal resistance to pitting and crevice corrosion.

- Q: Can stainless steel strips be used in the petroleum industry?

- Yes, stainless steel strips can be used in the petroleum industry. Stainless steel is known for its high resistance to corrosion, making it an ideal material for applications in the petroleum industry where exposure to harsh chemicals and corrosive environments is common. Stainless steel strips are often used in the construction of storage tanks, pipelines, and other equipment involved in the extraction, refining, and transportation of petroleum products. The durability and strength of stainless steel make it a reliable choice for withstanding the extreme conditions and pressures often encountered in the petroleum industry. Additionally, stainless steel's resistance to temperature fluctuations and its ability to maintain its structural integrity even in high-temperature environments further contribute to its suitability for use in this industry.

Send your message to us

Cold Rolled Stainless Steel Coil 304 Wide/Narrow Strip 2B/BA Finish

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords