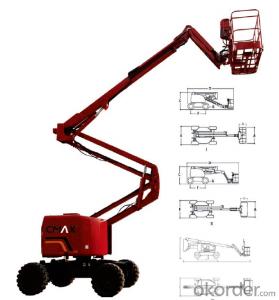

CMAX TRIPLE MAST ALUMINIUM AERIAL WORK PLATFORM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX TRIPLE MAST ALUMINIUM AERIAL WORK PLATFORM

Four/Five/Six mast aluminium aerial work platform are

available as per client more working height requirements.

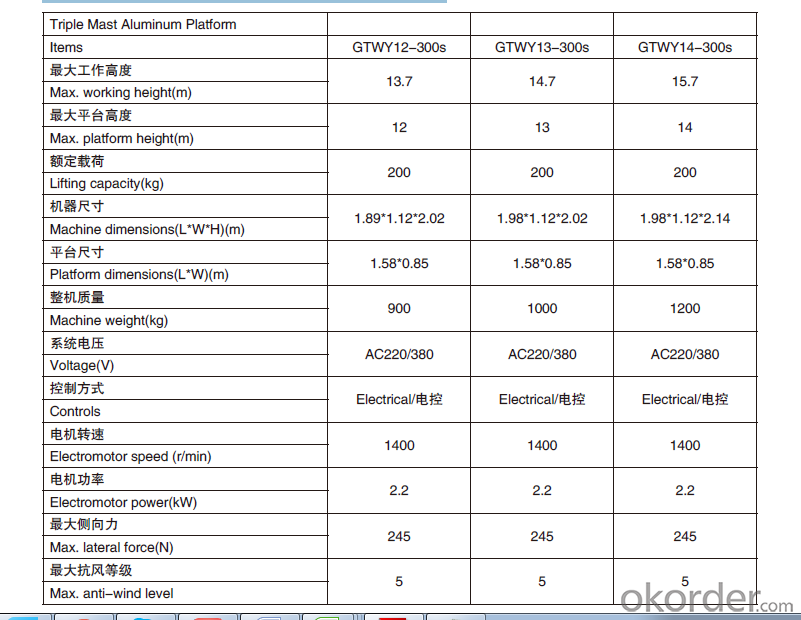

Specifications

Triple Mast Aluminum Platform

FAQ

1. why chose us?

China National Building Materials (Group) Corporation (CNBM), established in 1984,now is one of the largest state-owned group corporation in China, dealing with building materials & industrial equipment. Up to year 2010, CNBM Group's total asset is 20 billion USD and total staff is more than 100,000.CNBM International Corporation, specializes in designing & manufacturing of various

kinds of construction machinery, including tower crane, building hoist, etc. All the equipment produced by CNBM are compliant with the National level quality standard, and wins great reputation for their endurable performance in worldwide markets.

2.How about the shipment?

You can put 2 sets of of wheel loaders in one 40HQ container. The spare parts are packed with boxes.

The delivery time is 20 days.

3. What about your service?

We have our factory, we can meet customers needs as soon as possible.

We have first rate professional technology and provide good after-sales service.

4.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

- Q: What are the mandatory requirements for the use of gondola cars?

- (2) the construction site of the basket must be supervised, and the guardians are forbidden to leave the operation site. 3) the new basket prohibits anyone from changing its mode of use, including fittings and fittings.

- Q: Is the hanging basket heavy or heavy underneath?

- Hello hanging basket + body + three bar mechanism + + Cable + large wire rope counterweight and the safety rope. When purchasing price asked I need to know the type of purchase basket is the commonly used type 630 is a load of 630 kg) column length is generally 6 meters, width of *70cm), and then ask the live wire tail the wire diameter

- Q: Construction; basket; detection proportion

- Hello, height operation basket also belongs to construction hoisting machinery. "Construction crane safety inspection procedures" refers to the construction of lifting machinery, refers to the housing construction sites and municipal engineering sites used tower cranes, construction lifts and high operating basket. Therefore, in accordance with the requirements of the construction, lifting equipment installation, must be commissioned by qualified units for testing and acceptance. According to the regulations, the height hanging basket is the same as the tower crane and the construction elevator. Before installation, it must be checked and accepted before being put into use

- Q: What qualification does the hanging basket for production and construction require?

- 1, basket company qualification certificate 2, basket holder certificate 3, basket installation program 4, use the basket in the construction process of emergency plan (two copies, construction unit out one, labor service one)

- Q: How many kinds of basket are there?

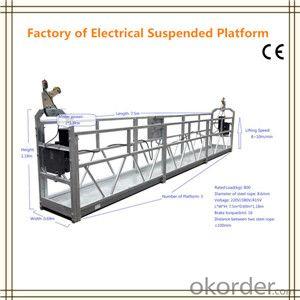

- Hanging basket is the construction machinery of aerial work in construction engineering. It acts on the curtain wall installation and the outer wall cleaning. The hanging basket is a new type of height working equipment which can replace the traditional scaffold, reduce labor intensity, improve work efficiency and can be reused.

- Q: What are the basic components of the overhead hanging basket?

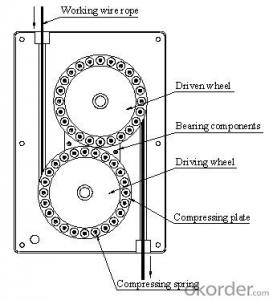

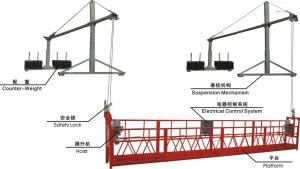

- The front end of the suspension mechanism is provided with a rear counterweight to overcome the overturning moment at the front end. The steel rope is hung on the hanging mechanism, and the steel rope is divided into a work rope and a safety rope. The hoist is normally climbing type, wire rope hoist is wound in a circle, hoist and hoist platform connected with the steel wire rope climbing platform. Safety at work rope break when the suspension platform lock on the safety rope

- Q: How to transplant basket?

- If it is new, then add the soil in the new pot, and then cut down the plant and plug it on the surface of the new soil, pay attention to it!! The soil can not be over the heart. Just water it. No matter what kind of transplant, it's the same thing

- Q: What are the kinds of basket?

- 7, white Chlorophytum plant Description: main leaf veins with white streaks of purple.8, Chlorophytum plant Description: main leaf veins purple.9, green plants Chlorophytum Description: main vein of leaf is green.

- Q: Kind of basket flower, how to raise?

- Apply liquid fertilizer every two weeks during the growing season. The leaves and flowers should be less nitrogenous fertilizer, otherwise the white or yellow markings on the leaves will become less obvious. Stop fertilization when ambient temperature is below 4 degrees.

- Q: How much money one day rental basket

- Look at the duration of the tenant, half a year would be 50 yuan, a month on the expensive, at least 70, the cost must be tenant out.

Send your message to us

CMAX TRIPLE MAST ALUMINIUM AERIAL WORK PLATFORM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords