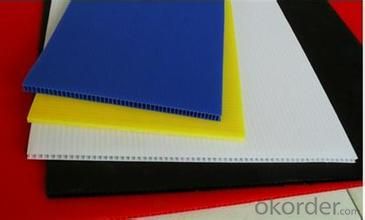

CMAX Polypropylene sheet wide used as package material

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX PP sheet is an extruded twin wall plastic sheet consisting of two flat walls connected by vertical ribs. Eco-friendly PP Plastic Hollow Sheet is mainly manufactured from a high impact co-polymer polypropylene (PP) or polyethylene (PE) resin, which can be recycling,washable,durable and reuseable etc.CMAX PP corrugated sheet, Plastic HollowSheets / Board / Signs has proved that it is suitable in the uses of packaging, advertising, construction, agriculture, industry and Pharmaceutical etc.

Specification:

1. Thickness: 2mm,3mm,4mm,5mm,6mm,7mm,8mm,10mm,12mm

2. Weight: From 250g/m2 to 3500g/m2

3. Standard Size: 2440mmx1220mm, 2000x1000mm, 1200x800mm, 1000x1000mm or as request

4. Grade:Corona Treated, Anti-Static, Conductive, UV Stabilized and Flame Retarded etc;

Feature:

PP corrugated sheet offers efficient solutions to a wide variety of applications. Compared to alternatives such as cardboard, metal or rigid plastic, Eco-friendly Twin Wall Corrugated Plastic Polypropylene PP Hollow Sheet offers the following unique advantages

1. Economical : both in use and purchase

2. Flexible : as a material and as application

3. Environmentally sound : recyclable

4. Water and moisture resistant

5. Approved for food packaging

6. Strong and durable

7. Lightweight

8. Good chemical resistance

9. Easy to print

- Q: What are the standards for carton boxes?

- Six angle drum turning testPut the carton into the six corners revolving drum with the impact plate, rotate according to the specified number of revolutions and times, and then check the damage of the goods and cartons.The above dynamic experiments are destructive and improve the resistance to damage of cartons and commodities by using cushion linings, partitions or other protective measures in the packaging of goods. In addition, some cartons need to be tested for spraying, weather resistance, etc., according to the contract agreement between the two parties.

- Q: What enterprises need wooden packing box?

- Material classification1. Wooden packing box: packing container made of wood and bamboo.2. No fumigation packing box: packing container made of composite material.3, strong safety: plastic packaging container for patent engineering plastics made by special technology.4, corrugated packaging box: it is through die cutting, indentation, nail box or sticky box made of corrugated cardboard boxes. Corrugated box is one of the most widely used packing products.

- Q: Is the packing box for express delivered by ourselves or by courier company?

- Courier to the packagingAccording to kg and mileage, you say something so small not much money, give you a web site, there are many express phone, you can consult some express, can talk about the price, I cross provinces express a gauge to spend 12 yuan, courier packaging is done, good. The instrument is normal.

- Q: What's the difference between wooden case packing and plywood packing?

- Wooden pallets to be sterilized, and now on the wooden pallets as long as the seal of IPCC can be, and do not have a certificate of disinfection.Plywood is the most convenient, and there is no need to consider the certificate of disinfection.

- Q: What's the square of the packing box?

- The packing box is a cube, so you have to work out the area of its 6 sides. Plus the overlap of the upper and lower openings of the packing carton and an overlap area around it. You can see the carton fully unfolded.

- Q: What's the packing box, gross weight?

- Net weight = the weight of the product itselfGross weight = the weight of the product itself + the weight of the outer packing

- Q: Is the outer packing case and the turnover case a concept?

- In some cases, the two refers to a traditional logistics and some of the goods are often carried out directly with the outer packing box turnover, with the construction of modern logistics system, this situation is less and less

- Q: How do I distinguish between package types?

- Packaging materials classification: can be divided into wooden products packaging, paper products packaging, metal products packaging, glass packaging, ceramic packaging and plastic products packaging.

- Q: What are the requirements for export packing?

- Must comply with the relevant laws and regulations of the state and the requirements of customers. As stipulated by the United States government, no processed Chinese wooden packing shall be allowed to enter the country; the provisions of the Arabia state shall ban the packaging of imported goods and forbid the design of six star patterns. In addition, if the customer sets some specific requirements for packaging, it should be satisfied as required and possible.

- Q: What are the requirements for product packaging?

- The product in the container must be securely fixed and shall not be moved. The fixing method is selected according to the structure of the product, which is fixed by bolts or pressed tightly with wooden arris (block). In the use of wooden block (block) fixed products, is strictly prohibited to pad and press the weak parts of products, such as: electronic control products, glass doors.

Send your message to us

CMAX Polypropylene sheet wide used as package material

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches