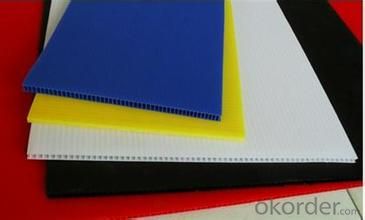

Extruded Polypropylene Package Sheet with different colors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Extruded Polypropylene Package Sheet is an extruded twin wall plastic sheet consisting of two flat walls connected by vertical ribs. Eco-friendly PP Plastic Hollow Sheet is mainly manufactured from a high impact co-polymer polypropylene (PP) or polyethylene (PE) resin, which can be recycling,washable,durable and reuseable etc.CMAX PP corrugated sheet, Plastic HollowSheets / Board / Signs has proved that it is suitable in the uses of packaging, advertising, construction, agriculture, industry and Pharmaceutical etc.

Specification:

1. Thickness: 2mm,3mm,4mm,5mm,6mm,7mm,8mm,10mm,12mm

2. Weight: From 250g/m2 to 3500g/m2

3. Standard Size: 2440mmx1220mm, 2000x1000mm, 1200x800mm, 1000x1000mm or as request

4. Grade:Corona Treated, Anti-Static, Conductive, UV Stabilized and Flame Retarded etc;

Feature:

PP corrugated sheet offers efficient solutions to a wide variety of applications. Compared to alternatives such as cardboard, metal or rigid plastic, Eco-friendly Twin Wall Corrugated Plastic Polypropylene PP Hollow Sheet offers the following unique advantages

1. Economical : both in use and purchase

2. Flexible : as a material and as application

3. Environmentally sound : recyclable

4. Water and moisture resistant

5. Approved for food packaging

6. Strong and durable

7. Lightweight

8. Good chemical resistance

9. Easy to print

- Q: What kind of wood is commonly used in wooden packing boxes?

- The frame wooden structure can be divided into class I (within the frame wooden box): frame member in the inner box board, suitable for general contents; class II (frame wooden box): frame structure in the outer box plate, applies in the length direction as a whole, and has sufficient rigidity to the contents. The basic provisions of its design consider the usual conditions of transportation, loading and unloading and storage.

- Q: How can the packing box be mounted onto the board?

- There are two kinds of steel box: one is a steel belt with a tray, and two is a wooden box without a tray. Compared with the traditional wooden case, its characteristic is: it is easy to disassembly, reliable connection: products can be folded after storage, and the use of steel edge connection, greatly reducing the transportation cost, effectively saving storage space. It is a good choice for long-term transportation and long-term storage. It is suitable for packing articles under the weight of 2 tons. Usually, the box can be split into six pieces (S type) or three (P), which is easy to transport and assemble when used. The length is usually around 300mm - 2000mm.

- Q: Can the express company provide the computer's packing box?

- When mailing an item, the courier company may provide a package service for the sender, but there is no requirementProvide the packaging with the goods needed by the sender.Solution: if you send a computer, you can communicate with the courier in advance,The package needed for the purchase of the package must be carried by the sender

- Q: Can the wooden packing box be transported by air directly? Or do you want to ship it in an air only container?

- Before the wood is packed, the wood needs to be fumigated before it can be transported by air. The same is true of shipping. The products packed in wood must be fumigated, and some countries are very sensitive to the transportation of wood. But the plywood doesn't need to be fumigated.

- Q: What's the difference between wooden case packing and plywood packing?

- Plywood is a kind of synthetic packing material, which is generally used as an export package. Wooden boxes are usually made of logs and wooden boards. Most of the customs and quarantine departments in the country require that they be treated by fumigation. The wooden boxes after fumigation should be labeled with fumigation heat treatment. Fumigation is the use of chemicals in the logs of insects killed, heat treatment is high temperature, high humidity, killing insects. Heat treatment can also reduce the moisture content of wood, fumigation can not.

- Q: How to prevent harmful substances in wooden packing box

- Generally speaking, these substances are divided into three kinds of fatigue: fungi, boring worms and marine boring animals. The most serious damage to wood is micro-organisms, which are mainly wood hiring bacteria and a small number of bacteria harm, so we are doing wood preservation, mainly to study the prevention of these fungi hazards. The growth of fungi must have four essential conditions: suitable temperature, adequate oxygen supply, adequate moisture, and nutrients suitable for the growth of fungi. If the four conditions are missing, they will prevent or prevent the erosion of fungi.

- Q: How about a carpenter's packing case?

- First introduce the core board1, big core board is also called blockboard, is in the middle of the two pieces of wood veneer splicing board and clamp. The wood and wood veneers in the middle are made of adhesive glue, so the formaldehyde release of many large core boards is beyond standard.2, the purchase of large core board must buy regular manufacturers of E1 products.Choose to observe its appearance, see big core board surface is smooth, without warping, deformation, there is no bubble, depression, the best can be opened the article core observation internal is uniform and tidy, the smaller the gap, and should not have decayed, fracture, wormhole, knot etc..Buy Daxinban, businesses tend to have many piles of stacked Daixinban a picture, can choose new Duitou (ashLess, wood color new) put a few of its big core board up, fan about, smell the taste of the drift out, without stimulation, environmental protection is relatively good.

- Q: How to calculate the cost of producing the packing box?

- Consider the fact that the proportion of the main raw material in the paper packaging enterprise is relatively high, when calculating the cost of the product, consider the material cost without considering other costs, such as the cost of wages and manufacturing costs.Finally, according to this month's production cost = pre production + current investment - this period in the formula of production can be calculated.

- Q: Does the air conditioner packing box contain the connecting copper pipe and the outer machine bracket?

- The household air conditioner packing box usually has the connecting copper tube, which is placed in the packing box of the outdoor machine. But there is no stent in the packing case.The copper aluminum connecting pipe is a new technology, some brands have a small amount of use, and the copper aluminum connecting pipe does not affect the service performance of the air conditioner, and the utility model can be used safely.There is that the central air-conditioning is generally large units, is not placed in the connecting pipe.

- Q: What are the general requirements for packing the goods by air?

- In addition to the goods packed in paper bags (such as documents, data, etc.), the checked goods should be packed with packing straps. It is prohibited to use straw bags or rope strapping goods packaging. F. the packing belt used for the binding of the goods shall be able to bear all the weight of the goods and shall ensure that the goods are not broken when they are carried.

Send your message to us

Extruded Polypropylene Package Sheet with different colors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords