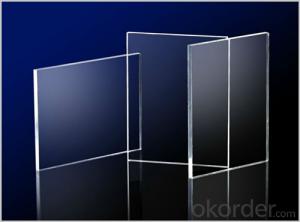

Anti-static Polypropylene Package Sheets Made of 100% Vrigin Material

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Anti-static Polypropylene Package Sheets Made of 100% Vrigin Material

Description | PP hollow sheet/PP corrugated sheet is a kind of environmental material, which is pollution-free and recyclable, made of polypropylene (PP) and polyethylene (PE) | |||||||||

Width | ≤2100mm | |||||||||

Length | As required. | |||||||||

Thickness | 2mm | 3mm | 4mm | 5mm | 6mm | 8mm | 9mm | 10mm | 11mm | 12mm |

GSM | 250-500 | 300-600 | 600-900 | 800-1200 | 900-1600 | 1400-2000 | 1600-2000 | 1600-2200 | 2200-2400 | 2400-2600 |

Application | Packing | Transfer Box,mail box,display rack,partition,gift box,food packing,turnover box,dustbin,etc. | ||||||||

Advertising | Sign board,exhibition board,billboard,caution board,picture frame backing,digital printing and screen printing. | |||||||||

Decoration | Partitions,wall cladding,indoor and outdoor decoration,windows and false ceilings,floor cover,greenhouse roof. | |||||||||

Stationery and art design | It has multi-color,suitable for art design & various pattern box or delicate gift pack. | |||||||||

Feature | Light weight,rigid,strong and long time durable. | Waterproof,moisture resistance,excellent weather ability. | ||||||||

Chemical resistance,anti-impact,fade resistance. | Environmental friendly,recyclable,washable,non-toxic. | |||||||||

Easy to fabricate,custom-made cut shape. | Excellent surface for paints and inks easily,anti-corrosion. | |||||||||

Grade | Common,Corona Treated,Anti-Static,Conductive,UV Stabilized,etc. | |||||||||

Color | Clear,Black,White,Blue,Red,Yellow,Green,Pink,Or as required. | |||||||||

Advantage | Capacity:600MT per month; Prompt delivery; Factory Direct Selling; ISO-9001 | |||||||||

- Q: Is the packing box for express delivered by ourselves or by courier company?

- Express goods packaging boxes prepared by the customer himself, if you need to express delivery, you need to give certain fees: 1-5 yuanExpress packing box by the company unified order, its packaging box with the company logo, name, two-dimensional code, the official website and other related categoriesExpress package cost does not belong to mailing costs.Remarks: under normal circumstances, there are extra cartons for express outlets which are willing to offer to customers free of charge. If not provided, they are within the reasonable scope.

- Q: What's the square of the packing box?

- Material classification1. packing container made of wood and bamboo in wooden packing case2. non fumigating packing box made of composite material3. strong plastic packaging container safety box for patent engineering plastics made by special technology.4. corrugated packaging box is through die cutting, indentation, nail box or sticky box made of corrugated cardboard boxes. Corrugated box is one of the most widely used packing products.

- Q: How to calculate the cost of producing the packing box?

- Direct labor is the production workers the wages of workers, according to the actual amount of time each number is allocated if the time statistic is not accurate, can according to the actual price of the price is the variety of merchandise value as the standard for distribution, distribution of the selected standard, since the code in an accounting period do not change;

- Q: How can I remove the words from the wooden packing box?

- Only use the day to take water and other things, with a towel to get wet, and soak the place where the seal will be diluted. Because the materials of atomic and so forth are compounds, it is only the solvent of the compound that dissolves it.

- Q: How do I distinguish between package types?

- Classification of packaged goods: can be divided into food packaging, pharmaceutical packaging, light industrial product packaging, needle cotton fabric packaging, household electrical appliances packaging, mechanical and electrical products packaging and fruit and vegetable packaging. Classification of safety: for general cargo packing and packing of dangerous goods.

- Q: Where do you use wood containers?

- Can use wood packing box where we live from and be too numerous to enumerate, various related supplies and food to the processing plant products, machinery and equipment to, more far, expensive crafts packaging will also use wood packing box, wood box to loading watches, pen, large loading cars, large machinery and equipment that should be used in packaging box.In the final analysis, as long as the goods are to be transported, they need to be packed; to better protect the contents of the box, consider the use of load-bearing properties, compression, impact resistance of wood packaging box. Careful, you can also find that the bottom of the container is also wood.I hope my answer will help you. If you don't feel clear enough, you can add questions, and I will always pay attention to your problems.

- Q: What are the L and R stands for steel cord packages?

- The direction of the take-up is mainly related to the direction of the spindle's discharge in the tire factory, because the discharge system is in a direction, clockwise or counterclockwise.

- Q: What's the name of the material used in paper packing boxes?

- According to the structure of the corrugated section, can be divided into A, B, C, D, E five corrugated cardboard. In accordance with the number of layers of corrugated can also be divided into one layer, double, three, five, seven layers of cardboard (ie three corrugated cardboard). Corrugated cardboard is the main feature of:(1) corrugated cardboard boxes made of corrugated cardboard are usually transported in the form of folding or tiling, which is easy to handle, improves transportation efficiency and saves storage space.(2) the cost of making corrugated cardboard packing boxes is low, and the materials are saved.(3) the utility model has the advantages of high strength and good buffering performance, and can avoid the collision and impact of the packaged goods, and is especially suitable for the transportation and packing of heavy products such as machinery, electromechanical, etc..(4) the production of corrugated boxes can be carried out on highly mechanized and automated equipment with high efficiency.

- Q: What are the general requirements for packing the goods by air?

- In addition to B. packaging should be suitable for the nature of the goods, state and weight, but also convenient handling, handling and stacking; packing surface can not have protruding nails, thorn hook, etc.; packaging should be clean, dry, no odor and grease.

- Q: What are the requirements and procedures for exporting wooden packing boxes?!

- The export packing cases are made of wood as boxes and wooden boxes made of plywood. Plywood boxes are used in machinery, chemicals, electronics, hardware and other fields due to their flexibility in packing, adaptability to loading and reuse. Containing box plate and the fastening connector, and box board box adjacent box plate perpendicular to each other via the fastening connector, card stud connectors at the edge of each box plate are respectively fixed around the outer surface of a certain number of steel, the steel plate box adjacent card stud connectors respectively through angle at the adjacent board vertical junction connecting piece is provided with a long hole, and the end of the reverse bending fixed, the adjacent box plate is vertically fixed and connected, and a packing box.

Send your message to us

Anti-static Polypropylene Package Sheets Made of 100% Vrigin Material

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords