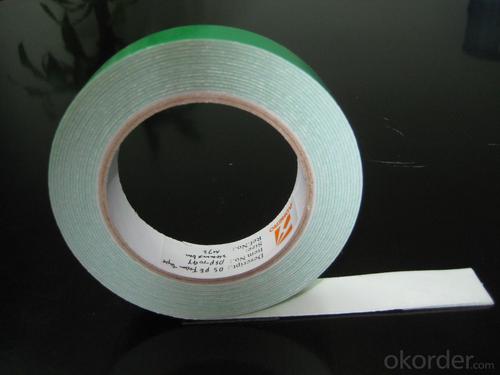

Clear Industrial Packaging Tape - Double Sided EVA Foam Tape with Acrylic Adhesive

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

CONSTRUCTION Of Double Sided Pothook Use EVA Foam Tape:

Backing: EVA Foam (Black/White)

Adhesive: Hot melt rubber adhesive.

Liner: White/Yellow

TYPICAL PHYSICAL PROPERTIES Of Double Sided Pothook Use EVA Foam Tape:

Total Thickness (adhesives + backing): 3 mm

Initial Tack: ≥12# (steel ball)

Peel Adhesion: more than 20 N/25mm (to steel)

Holding power(hrs): 50

Elongation(%): 100

Temperature resistance: 60 Degree Celsius

Sizes Of Double Sided Pothook Use EVA Foam Tape:

Jumbo Roll: 1.00 x 100m

Cut Roll: As per customer’s requirements

Application Of Double Sided Pothook Use EVA Foam Tape:

Holding of minor objects, bond between rough surfaces, reduce vibration & shock.

Bond & adhesion of various hooks, boards, mirrors.

Remarks Of Double Sided Pothook Use EVA Foam Tape:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and be kept away wet and/or heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

FAQ

Q 1:Do you have any MOQ of your adhesive tape ?

A:Yes, according to the size you need.

Q 2:What is the delivry time?

A:Sample time 7 days, 30 days for the mass production.

Q 3:Can we put our logo on the products?

A :Yes,welcome.

- Q: Is packaging tape easy to tear by hand?

- Yes, packaging tape is generally easy to tear by hand. Most packaging tapes are designed with a serrated edge or perforation, making it easy to tear off a desired length without the need for scissors or any other tools. This feature allows for quick and convenient packaging and sealing of boxes or packages without any hassle. However, it is important to note that the ease of tearing may vary depending on the brand and quality of the packaging tape.

- Q: How do I store packaging tape?

- To store packaging tape, it is best to keep it in a cool, dry place away from direct sunlight and extreme temperatures. A drawer, cabinet, or a dedicated storage box would work well to prevent the tape from getting damaged or losing its adhesive properties. It is also advisable to keep the tape in its original packaging or use a tape dispenser to keep it organized and easily accessible when needed.

- Q: Is packaging tape easy to tear by hand?

- Packaging tape is usually quite simple to tear by hand. Many packaging tapes have a serrated edge or perforation, enabling effortless tearing to achieve the desired length, eliminating the need for scissors or additional tools. This characteristic facilitates swift and convenient packaging and sealing of boxes or packages, without any complications. Nonetheless, it is crucial to acknowledge that the ease of tearing may differ based on the brand and quality of the packaging tape.

- Q: How many tapes do you need to make a tape? How do you calculate a mother roll and how many tapes do you make?To make a tape, you need a roll,1, how to calculate a mother roll, how many tapes do?2, now the mother rolls have what specifications?3. How much is the mother volume now?4, how do you calculate the profit of a roll of tape?

- 1 how much roll tape does a square of a mother roll divide by the square of a single adhesive tape. Of course, this includes lossExample: the square of a volume is 4800, and the square of a tape of a specification of 60*45.7 is about 2.74, then the volume of the tape isEqual to 1751 rolls, because there is a loss of about 1700

- Q: Can packaging tape be printed with custom logos or designs?

- Yes, packaging tape can be printed with custom logos or designs. This allows businesses to personalize their packaging and promote their brand identity. Custom printed packaging tape can also serve as a marketing tool by creating a professional and eye-catching appearance for packages.

- Q: How does packaging tape perform on rubber surfaces?

- Packaging tape performs relatively well on rubber surfaces. The adhesive on packaging tape is designed to adhere to a variety of materials, including rubber. When properly applied, packaging tape provides a strong bond to rubber surfaces, effectively securing packages or materials together. However, it is important to note that the effectiveness of packaging tape on rubber surfaces may vary depending on the specific type of rubber and the condition of the surface. In some cases, the tape may not adhere as strongly to certain types of rubber, especially if the surface is rough or dirty. It is always recommended to clean and dry the rubber surface before applying packaging tape for optimal adhesion. Additionally, extreme temperatures and moisture may affect the performance of packaging tape on rubber surfaces, so it is advised to store and use the tape within the recommended temperature range and avoid exposing it to excessive moisture. Overall, packaging tape can provide a reliable and secure bond on most rubber surfaces, making it a suitable choice for packaging and securing materials.

- Q: How do I prevent packaging tape from getting tangled?

- Here are several suggestions to prevent packaging tape from becoming tangled: 1. Invest in a tape dispenser designed specifically for packaging tape. This dispenser incorporates a built-in cutting blade and roller mechanism that will help maintain control over the tape and prevent tangling. 2. Before applying the tape, ensure that the surface is clean and free of dust, debris, or any other potential obstructions that could cause the tape to stick and tangle. 3. Minimize handling of the tape as much as possible, as each time it is touched, there is a greater likelihood of it twisting or tangling. Handle the tape only when necessary. 4. Use a sharp cutter or a dispenser with a cutting blade to make clean and straight cuts. Uneven or jagged cuts can cause the tape to twist or tangle as it is unrolled or applied. 5. Store the tape properly when it is not in use. Keep it in a cool and dry place, away from direct sunlight or extreme temperatures. Additionally, keeping the tape in its original packaging or a designated container can help prevent tangling. 6. When unrolling the tape, hold the roll firmly and apply a slight tension to keep it straight. Avoid jerky movements or pulling the tape too forcefully, as this can cause it to twist or tangle. By following these suggestions, you can reduce the likelihood of packaging tape becoming tangled, resulting in a smoother and more efficient packaging process.

- Q: Does packaging tape come in different colors?

- Yes, packaging tape is available in different colors.

- Q: What are the common price ranges for packaging tape?

- The pricing of packaging tape varies based on the type, brand, and quantity of tape you are buying. Basic packaging tape typically costs between $2 and $10 per roll, with lower quality or smaller rolls being cheaper. Mid-range packaging tapes, which may offer better durability or adhesive strength, can be priced from $5 to $20 per roll. Premium or heavy-duty packaging tapes, commonly used for industrial or professional purposes, can range from $10 to $30 per roll. Additionally, you can find bulk packaging tape options that come in packs of multiple rolls, which may have slightly discounted prices. To get the best deal, it is important to consider your specific packaging requirements and compare prices from different suppliers.

- Q: Can packaging tape be used for sealing envelopes?

- Yes, packaging tape can be used for sealing envelopes. It provides a strong and secure seal that helps protect the contents of the envelope.

Send your message to us

Clear Industrial Packaging Tape - Double Sided EVA Foam Tape with Acrylic Adhesive

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords