Chopped Fiberglass Strands 1 Fiberglass Powder Chopped Stand Mat General Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Technique: | Chopped Strand Fiberglass Mat (CSM) | Dimensions: | 450gsm | Mat Type: | Continuous Filament Mat |

| Fiberglass Type: | E-Glass | Softness: | softness | Place of Origin: | Jiangxi, China (Mainland) |

| Brand Name: | cnbm | Model Number: | 450gsm | color: | white |

| fiberglass type: | E glass | product: | e-glass powder chopped stand mats | binder: | powder or emulsion |

| width: | 1040 or 1270mm, as your requirement | weight: | 30 or 45kg/roll | paper tube diameter: | 90mm |

| outer diameter of roll: | 256mm | packing: | plastic film+carton box + pallet |

Packaging & Delivery

| Packaging Details: | plastic film+carton box + pallet |

| Delivery Detail: | 15-20days |

Specifications

1.e-glass powder chopped stand mats

2.binder:power or emulsion

3.width:1040mm or 1270mm

4.weight:450gsm

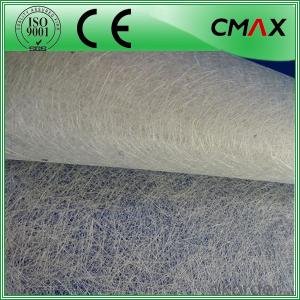

Picture

- Q: Can fiberglass chopped strand be used to reinforce concrete?

- Yes, fiberglass chopped strand can be used to reinforce concrete. It is commonly used as a replacement for traditional steel reinforcement due to its high tensile strength, corrosion resistance, and ease of handling and installation. The chopped strands are added to the concrete mix to improve its overall strength and durability.

- Q: Can fiberglass chopped strand be used in the production of consumer packaging?

- Indeed, fiberglass chopped strand can be utilized in the manufacturing of consumer packaging. Serving as a reinforcement material, fiberglass chopped strand consists of small pieces created by chopping strands of fiberglass. It finds wide application as a reinforcement material in various fields, including consumer packaging. When employed in consumer packaging, fiberglass chopped strand imparts additional strength and durability to the packaging material. This aids in preventing the packaging from tearing or breaking, thereby ensuring the secure and protected containment of the product within. Furthermore, fiberglass chopped strand enhances the overall structural integrity of the packaging, rendering it more resistant to external pressures and impacts. Moreover, fiberglass chopped strand possesses the qualities of being lightweight and versatile, making it compatible with diverse types of consumer packaging materials. It can be effortlessly incorporated into plastics, paper, or other packaging materials during the manufacturing process. Consequently, this allows for flexibility in packaging design and customization while still providing the essential strength and durability. In summary, the utilization of fiberglass chopped strand in the production of consumer packaging serves to elevate the quality and performance of the packaging material, effectively meeting the requirements and expectations of consumers.

- Q: Can fiberglass chopped strand be used for reinforcing rubber materials?

- Yes, fiberglass chopped strand can be used for reinforcing rubber materials. Fiberglass chopped strand is commonly used as a reinforcement material in various industries, including rubber manufacturing. When added to rubber compounds, it enhances the mechanical properties of the rubber, such as tensile strength, tear resistance, and dimensional stability. The fiberglass chopped strand is typically mixed with the rubber material during the compounding process, and it helps to improve the overall performance and durability of the rubber products. Additionally, fiberglass chopped strand provides excellent adhesion to rubber, ensuring a strong bond between the two materials. Therefore, it is a suitable option for reinforcing rubber materials.

- Q: How does the fiber alignment of fiberglass chopped strand affect the strength of composites?

- The strength of composites greatly depends on the fiber alignment of fiberglass chopped strand. If the fibers are aligned in a particular direction, they contribute to the overall strength and stiffness of the composite material. This alignment also affects how stresses and strains are distributed within the composite structure. In composites, the fibers reinforce the matrix material, providing strength and rigidity. When the fiber alignment is random or unidirectional, the composite becomes more isotropic, meaning the strength is the same in all directions. This is useful in applications where the load is applied from all directions, like pressure vessels. However, when the fibers are aligned in a specific direction, the composite becomes anisotropic, with higher strength in the aligned direction. This is advantageous in applications where the load is primarily in one direction, such as beams or columns. The aligned fibers can better resist tension or compression forces, enhancing the overall strength and stiffness of the composite material. Furthermore, fiber alignment also affects the bond between the fibers and the matrix material. Well-aligned fibers create a larger contact area, leading to improved load transfer and enhanced mechanical properties. This results in increased strength, toughness, and resistance to delamination. In conclusion, the fiber alignment of fiberglass chopped strand has a significant impact on the strength of composites. Whether the fibers are randomly dispersed or aligned in a specific direction, it determines the overall mechanical properties of the composite material, including strength, stiffness, and resistance to different types of loads.

- Q: Is fiberglass chopped strand biodegradable?

- Fiberglass chopped strand does not possess biodegradability. It comprises glass fibers and a polymer resin, forming a reinforced plastic. The glass fibers do not naturally disintegrate, and the polymer resin is commonly non-biodegradable too. Consequently, fiberglass chopped strand will endure in the environment for an extended period and will not undergo decomposition via natural mechanisms.

- Q: Is fiberglass chopped strand suitable for the production of marine components?

- Marine components can be effectively produced using fiberglass chopped strand. Fiberglass is widely recognized for its remarkable strength-to-weight ratio, resistance to corrosion, and long-lasting nature, making it an ideal choice for marine applications. Chopped strand refers to the short fibers of fiberglass that are combined with resin to create a composite material. This particular type of fiberglass is commonly utilized in the construction of boats, yachts, and other marine components. Fiberglass chopped strand brings forth several benefits when used in marine applications. Firstly, it offers high tensile strength and stiffness, allowing for the creation of lightweight yet resilient components. This is crucial for marine vessels and structures since they must withstand the harsh conditions of saltwater, waves, and impacts. Furthermore, fiberglass chopped strand exhibits exceptional resistance to corrosion and deterioration caused by water and sunlight exposure. Consequently, marine components made from fiberglass have a lengthier lifespan and necessitate less maintenance in comparison to other materials. Moreover, fiberglass chopped strand can be easily shaped into various forms and sizes, enabling the production of customized marine components. It can be employed for the fabrication of hulls, decks, bulkheads, and other structural parts. The versatility of fiberglass chopped strand also permits the integration of other materials or reinforcements to meet specific requirements. In summary, fiberglass chopped strand is a suitable material for manufacturing marine components due to its strength, corrosion resistance, durability, and versatility. Its numerous advantages have made it a favored choice in the marine industry.

- Q: What are the transportation considerations for fiberglass chopped strand?

- Transportation considerations for fiberglass chopped strand include ensuring proper packaging and securing the material to prevent damage during transit. Fiberglass chopped strand is typically packaged in bags or boxes, and it is important to choose packaging that is sturdy enough to withstand the rigors of transportation. In addition to packaging, it is essential to secure the fiberglass chopped strand properly to prevent shifting or movement during transport. This can be done by using straps or other secure fastening methods to hold the packages in place within the transportation vehicle. Another consideration is the weight and size of the fiberglass chopped strand packages. It is important to accurately estimate the weight and dimensions of the packages to ensure compliance with weight restrictions and to determine the appropriate type of transportation vehicle needed. Furthermore, it is crucial to consider any special handling requirements for fiberglass chopped strand during transportation. This may include protecting the material from extreme temperatures, moisture, or other environmental factors that could potentially impact its quality. Lastly, it is important to be aware of any regulations or guidelines that govern the transportation of fiberglass chopped strand. This could include compliance with hazardous materials regulations, if applicable, or following specific shipping requirements mandated by regulatory bodies. By considering these transportation considerations, it is possible to ensure the safe and efficient transportation of fiberglass chopped strand, minimizing the risk of damage or loss during transit.

- Q: What are the advantages of using fiberglass chopped strand over other reinforcement materials?

- There are several advantages of using fiberglass chopped strand over other reinforcement materials. Firstly, fiberglass chopped strand offers excellent strength and durability. It has a high tensile strength, which means it can withstand heavy loads and stresses without breaking or deforming. This makes it an ideal choice for reinforcing various materials and structures, such as concrete, plastics, and composites. Secondly, fiberglass chopped strand is lightweight. Compared to other reinforcement materials like steel or aluminum, fiberglass is significantly lighter. This makes it easier to handle and transport, reducing labor costs and increasing overall efficiency. Additionally, fiberglass chopped strand is corrosion-resistant. Unlike metals such as steel, which can rust and deteriorate over time, fiberglass is not prone to corrosion. This makes it suitable for applications in harsh environments or where exposure to moisture, chemicals, or saltwater is common. Another advantage of fiberglass chopped strand is its electrical insulation properties. Fiberglass is a non-conductive material, meaning it does not conduct electricity. This makes it a preferred choice for applications where electrical insulation is crucial, such as electrical equipment, circuit boards, or insulation for wiring. Furthermore, fiberglass chopped strand is highly versatile. It can be easily molded and shaped to fit various forms and configurations, allowing for customized designs and applications. It also has excellent adhesion properties, enabling it to bond well with other materials, further enhancing its versatility. Lastly, fiberglass chopped strand is cost-effective. Compared to alternative reinforcement materials like carbon fiber, fiberglass is generally more affordable. This makes it a cost-effective choice for many industries and applications, without compromising on performance and reliability. In summary, fiberglass chopped strand offers numerous advantages over other reinforcement materials, including excellent strength, lightweight, corrosion resistance, electrical insulation, versatility, and cost-effectiveness. These qualities make it a preferred choice in various industries, ranging from construction and automotive to aerospace and electronics.

- Q: What are the environmental considerations when using fiberglass chopped strand?

- When using fiberglass chopped strand, there are several environmental considerations to take into account. Firstly, the production of fiberglass chopped strand involves the use of raw materials such as glass fibers, which are derived from non-renewable resources. The extraction of these resources can have a negative impact on the environment, including habitat destruction and energy consumption. Additionally, the manufacturing process of fiberglass chopped strand requires the use of chemicals and binders, which can potentially pose a risk to human health and the environment if not properly managed. These chemicals can be released into the air, water, or soil during production or disposal, leading to pollution and environmental contamination. Furthermore, fiberglass chopped strand waste can be a concern. Proper disposal of waste materials is important to prevent them from ending up in landfills or being incinerated, which can release harmful substances into the environment. Recycling and reusing fiberglass chopped strand waste can help reduce its environmental impact. Lastly, the use of fiberglass chopped strand in various applications can have both positive and negative environmental effects. On one hand, fiberglass is known for its durability and longevity, which can reduce the need for frequent replacement and thereby minimize waste generation. On the other hand, the production and use of fiberglass chopped strand can contribute to greenhouse gas emissions and energy consumption. To mitigate these environmental considerations, various measures can be taken. This may include using alternative materials that are more sustainable and renewable, implementing more efficient manufacturing processes to reduce resource consumption and waste generation, and properly managing and disposing of fiberglass chopped strand waste. Additionally, promoting recycling and reusing practices can help minimize the environmental impact of fiberglass chopped strand.

- Q: What are the typical sustainability considerations when using fiberglass chopped strand composites?

- When utilizing fiberglass chopped strand composites, there are several sustainability factors that should be taken into consideration. Firstly, the extraction of silica sand, a non-renewable resource, is involved in fiberglass production. It is crucial to assess the environmental impact of mining and processing silica sand, as well as the potential for habitat destruction and water pollution. Another aspect of sustainability to consider is the energy consumption associated with manufacturing fiberglass composites. The production process necessitates high temperatures for melting and shaping the material, resulting in significant energy usage. This energy consumption contributes to greenhouse gas emissions and climate change. Moreover, disposing of fiberglass chopped strand composites can be challenging from a sustainability standpoint. Fiberglass is not biodegradable and can persist in the environment for an extended period. To minimize waste and environmental impact, it is important to consider proper disposal methods such as recycling or finding alternative uses for the material. Furthermore, the health and safety of workers during the manufacturing process of fiberglass chopped strand composites should be taken into account. The production and handling of fiberglass can release harmful fibers and chemicals into the air, posing health risks to workers if not appropriately controlled. Ensuring worker protection and implementing suitable safety measures are crucial for sustainability in this context. To address these sustainability considerations, various initiatives and technologies are being developed. These include the use of recycled fiberglass, the advancement of more energy-efficient manufacturing processes, and the implementation of stricter regulations and guidelines to ensure safe production and disposal of fiberglass chopped strand composites. Overall, achieving sustainability when utilizing fiberglass chopped strand composites requires careful consideration of the environmental impact of raw materials, energy consumption during production, disposal practices, and worker safety. By addressing these considerations, the use of fiberglass composites can be made more sustainable and environmentally friendly.

Send your message to us

Chopped Fiberglass Strands 1 Fiberglass Powder Chopped Stand Mat General Purpose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords